Over the past six years, Vesconite Bearings has witnessed a significant uptick in its supply of bearings to Mexico—a testament to the growing recognition of Vesconite Hilube’s superiority over bronze.

LEAVING THE BRONZE AGE BEHIND

For decades, bronze had been the go-to material for manufacturing plain pump bearings in Mexico. Numerous local bronze foundries had historically been the backbone of the pump industry, supplying the industry with the various components that it needed.

However, as demands are growing more stringent, especially in sectors such as mining, where acidic water poses challenges to corroded traditional material components, the limitations of bronze as a bearing material have become apparent.

STANDING UP TO HARSH CONDITIONS

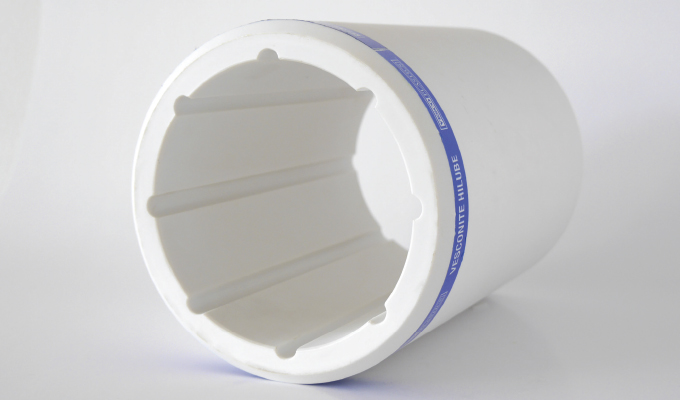

Vesconite Hilube is a bearing material that is resistant to acidic environments and the chemicals typically found in copper and gold processing. Where water acidity can wreak havoc on traditional materials, Vesconite Hilube stands resilient, maintaining its integrity and performance even in the harshest conditions.

In addition, unlike bronze, Vesconite Hilube bearings excel in dry start conditions, eliminating the need for external feed lines to prime pumps before startup and reducing wear and failure during startup—a common challenge in pump operations.

SERVICE YOU CAN COUNT ON

Besides these operational advantages, Vesconite Bearings has been able to back up its products with exceptional service and lead times, ensuring that manufacturers receive what they need when they need it, thus becoming a trusted supplier to various Mexican original equipment manufacturers.

While the merits of Vesconite Hilube are undeniable, Vesconite Bearings’ success in Mexico is also attributed to the company’s proactive approach to customer engagement, says Monique Potgieter, an application engineer with Vesconite Bearings.

She has been instrumental in fostering relationships with Mexican pump manufacturers and has undertaken five visits since 2021 to understand the unique needs and challenges of the market.

Potgieter says that Vesconite Bearings offers a comprehensive range of pump components to the Mexican market, including line shaft bearings, bowl bearings, suction inlet bearings, stuffing box bearings and casing wear rings.

FIT FOR YOUR APPLICATION

Vesconite Hilube is specifically recommended for moist and underwater applications. These include the pump and marine industry, where regular maintenance is not practically feasible or cost-effective. Displaying superior wear life, especially in poorly lubricated and dirty conditions, Vesconite Hilube has extended the life-cycle of components across myriad applications.

KEY FEATURES OF HILUBE

Vesconite Hilube is our flagship bearing material, designed for particularly difficult operating environments.

- No water swell

- Extended wear life

- Low friction

- High load-bearing strength

- Dimensional stability

- Shaft friendly

- Chemical resistance

FOR MORE INFORMATION

Vesconite Bearings is a world-leading manufacturer of low-friction, low-wear bearing materials for a wide range of industries. Selling to over 100 countries, these include the pump, agriculture, railways, mining, heavy transport, hydro, renewable-energy, earthmoving, marine, and construction industries. For more information, visit www.vesconite.com.

MODERN PUMPING TODAY, June 2024

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!