Low pressure sewer systems using semi-positive displacement grinder pumps have been employed extensively to provide central sewer service to areas where gravity sewer could not be installed and to provide a solution for the renewal of failed gravity systems.

A low pressure sewer system consists of a network of small diameter pressure pipes and individual pumping units that convey wastewater directly to a treatment facility or central sewer. Developed more than forty years ago, low pressure sewer systems have a large body of well documented experiences that show dependable operation, long term reliability, and lower life-cycle and social costs when compared to gravity sewers.

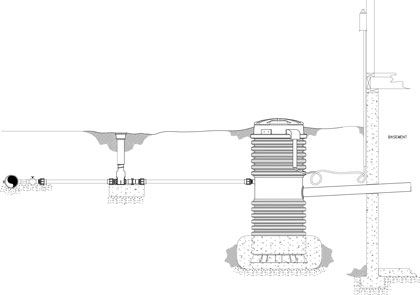

The primary component of a low pressure sewer system is a grinder pump station installed at each individual property in the system. The grinder pump station collects the wastewater, grinds the solids into small particles, and discharges it to the pressurized pipe network. Because the system is closed and pressurized, the grinder pump is capable of transporting sewage over two miles, depending on the topography and other system parameters. The pump unit is generally smaller than a household washing machine. Because it does not rely on gravity flow, the system provides more options and flexibility for siting.

Several manufacturers offer grinder pumps for low pressure sewer systems with a semi-positive specifically designed for household wastewater applications in low pressure sewer systems.

In addition to allowing for the passage of the ground solids without clogging, the geometry of a semi-positive displacement pump produces a nearly vertical pump curve. The flow from the pump is generally constant, and is somewhat independent of the pressure in the system. In practical terms, the pump characteristics means that, unlike a system using centrifugal pumps, when a semi-positive displacement pump is activated, it will deliver essentially the same flow rate, no matter where the operating point is within the allowable range of operating pressure.

The choice of the semi-positive displacement principle was made with input from the ASCE Staff and Steering Committee more than forty years ago based on these irrefutable hydraulic fundamentals. The development of the wastewater pump began with no vested interest in any particular technology, so the developers were free to start from the “ground floor” and devise a unique class of pump, tailored in every respect to the specific needs of pressure sewer systems.

In evaluating the equipment for use in pressure sewer systems, the designing engineer should begin with two main choices: first, select the pump characteristic (H–Q curve), either centrifugal or semi-positive displacement; second, select the equipment manufacturer based on additional pump characteristics, including:

- Performance features

- Reliability and track record in the “field”

- Ease of installation

- Serviceability

- Preventive maintenance requirements

- Real estimates of operating and maintenance costs

- Initial cost

- Life-cycle cost

LOW PRESSURE FOR SEWER RENEWAL

Most central sewer systems installed in the past use gravity as the moving force to transport wastewater to treatment facilities. Most systems, however, cannot convey the wastewater solely by gravity. Gravity sewers may not always be the best choice of a new or rehabilitated central collection system because of terrain, soil type, groundwater, and other factors. Excessively hilly or flat terrain requires deep excavations and large pump stations. Low pressure sewers using semi-positive displacement grinder pumps can be a cost effective solution to sewer renewal.

Over time, gravity sewers fail. Root intrusion, pipe cracks, joint failures, and other deficiencies allow excessive groundwater and stormwater to enter the system. Referred to as infiltration and inflow (I/I), this excessive flow has detrimental environmental and economic effects on the overall operation of the wastewater collection and treatment system. The excess flows, or essentially clean groundwater and rain water, can quickly overload the collection system capacity, resulting in sanitary sewer overflows (SSOs), backups of raw sewage into basements, and high operating costs and equipment wear due the transport of the excessive flows.

Limiting the amount of I/I in sewer systems through infrastructure renewal measures provides many economic, social, environmental, and public health benefits. Renewal of the collection system infrastructure includes options to return the system to an acceptable level of performance. Repair, rehabilitation, and replacement are a progression of the activities employed to address and renew failing infrastructure. Sewer replacement is an extensive approach to infrastructure renewal. Replacement involves the complete abandonment of the existing sewer pipe and the installation of a new pipeline. Unlike replacement with a gravity collection system (replace in kind) the replacement of a failed gravity sewer with a low pressure sewer system using semi-positive displacement grinder pumps can be viable and cost effective option.

Using small diameter pressurized pipe buried just below the frontline, a low pressure sewer system can be installed with low impact excavation techniques or with trenchless directional drilling methods. Additionally, a low pressure system eliminates essentially all excessive flows over the entire service life of the new system. Repair and rehabilitation methods used in sewer renewal can achieve limited I/I reduction. Because the wastewater in low pressure sewer systems is pumped under pressure through flexible sewer pipe, manholes are not required to change the direction or alignment of the mainline sewers. This eliminates the need to maintain and rehabilitate these ancillary structures.

Low pressure sewer systems used to replace failed gravity sewers can provide a complete sewer renewal with fewer disturbances to the community and have minimal environmental impact. Based on more than forty years of project comparisons, typical capital costs for low pressure sewer systems repeatedly range from 40 to 80 percent lower than gravity systems. This low capital cost advantage is enhanced by the lower social costs including less business disruption, traffic disruption, damage to adjacent surfaces, structures, and utilities, and noise and dust pollution, low pressure sewers provide.

Grinder pumps are typically installed outside of each home on the pressure sewer system. Only the access lid and alarm panel are visible to the homeowner.

CASE STUDY: ELWOOD, KANSAS

Elwood, Kansas, sits in the northeast corner of the state, just across the Missouri River from the city of St. Joseph, Missouri. It’s a residential and light commercial town built on alluvial sand soils deposited over thousands of years. The gravity sewer system was barely functional because of the groundwater infiltration in the deeply dug system, 15 to 20 feet (4.6 to 6 meters) in some places. Nine lift stations kept groundwater out of the system. Manholes and sections of main were constantly sinking.

The town suffered a devastating flood in 1993. Following an unusually large snowpack over the winter, wet weather continued throughout the spring, saturating soil and elevating rivers and streams well into the summer. Storms dumped heavy rainfall across Kansas—amounts achieving 75- to 300-year frequencies produced record flooding on the upper Mississippi and lower Missouri rivers. Levees protecting Elwood were breached, and the entire town was washed out. The soft, sandy soil became a porous, shifting hydrography that destroyed many structural foundations and the gravity sewer system.

Gravity sewer main in need of repair.

The Federal Emergency Management Agency (FEMA) helped Elwood dig out and patch up its severely compromised sewer. With funding from FEMA, the entire system was videotaped and shown to be nearly beyond repair. At this point, plans were laid to rebuild with a more sensible solution for this vulnerable area.

Instead of installing another gravity sewer system, the city decided to use LPS. Other towns nearby had used the system with great success. The flat topography and soil type further made the case against a gravity system. The new sewer system was installed in two phases. The first phase, installed in 2004, consisted of 245 grinder pump stations. The second phase, completed in 2008, added another 139 grinder pump stations.

The gravity system had required extreme depths to maintain a downgrade. This, in turn, created groundwater inflow problems that led to mains collapsing, manholes sinking and sections of roadways sinking. A constant repair requirement accompanied the system and was a constant strain on the Public Works Department budget. With nine lift stations pumping groundwater inflow around the clock, a breakdown of a single station had a catastrophic effect, as the entire system then backed up.

Due to this constant operation, Elwood’s lift stations wore out quickly. Between the electricity to run the lift stations and the repairs, the old gravity system was literally sending money down the drain. With the pressure sewer system, the grinder pumps run for shorter duration and the closed system doesn’t allow groundwater infiltration, eliminating collapses of roadways, mains, or manholes.

CONCLUSION

As existing infrastructure in the United States ages, many communities are replacing their gravity sewer systems with low pressure systems. A grinder pump- driven LPS is a viable and cost-effective alternative to I/I challenges. The right pump and a well-designed system mean elimination of I/I resulting in lower operating costs, and a satisfied and secure customer base. ■

_________________________________________________________________________

ABOUT THE AUTHOR

Keith McHale, P.E., is a professional engineer with more than twenty years of experience in wastewater collection and treatment, including gravity and pressure sewer design, and infiltration and inflow (I/I) evaluations. Keith is the I/I project manager for Environment One Corporation. He holds a BS in civil engineering from the University of Massachusetts at Amherst and is a member of WEF and NEWEA. For more information about E/One products, call 518.346.6161, email eone@eone.com, or visit www.eone.com/sewer.

_________________________________________________________________________

MODERN PUMPING TODAY, January 2014

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!

![]()