In the past, Stallkamp has repeatedly implemented projects for sewage treatment plants and the wastewater industry. In addition to various sludge tanks, this also included complex wastewater treatment plants such as a stainless-steel tank with a stainless steel floor or a funnel-shaped secondary clarifier. Stallkamp’s appearance at IFAT this spring is intended to strengthen its position in the wastewater segment.

Featured Image: Two stainless steel and one corrugated stainless-steel tank for the paper industry in Bavaria

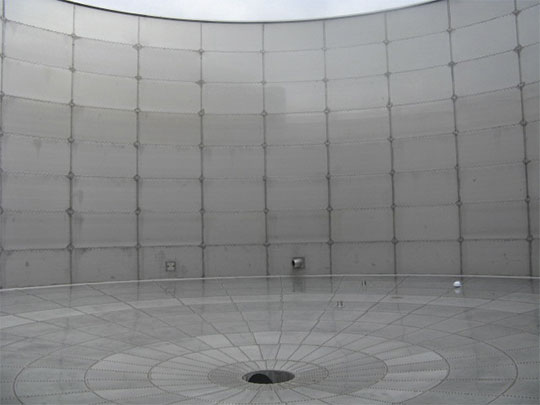

Above: Self-supporting stainless steel roof

MANY PROJECTS SUCCESSFULLY IMPLEMENTED

Erich Stallkamp ESTA GmbH has the necessary know-how is proven by various projects from the last twenty-five years. For example, an extensive wastewater treatment plant with two steel tanks (Ø15.52m, h=8.78m) was designed and installed in Bavaria as a wastewater collection tank. In addition, a corrugated steel tank (Ø2.75m, h=8.78m) serves as an equalising tank for the paper industry.

Larger wastewater pre-treatment plants have also been installed for the food industry, as a reference plant in North Rhine-Westphalia shows. A stainless-steel tank (Ø16.29m, h=10.03m) with self-supporting ribbed dome roof and various add-on parts was realised.

EXPERIENCE WITH SPECIAL DESIGNS

Stallkamp has also proved to be a reliable partner for special designs. In Herzebrock, for example, a sewage treatment plant with several clarifiers (Ø outside 24.00m, Ø inside 3.88m, h=4.18m) was developed, which is controlled by means of overflow heights. Also, the funnel-shaped secondary clarifiers (Ø top 7.65m, Ø bottom 1.40m, h=5.00m) with toothed gutter for a private brewery convinced with their stability and longevity.

Currently, a wastewater project with three stainless steel tanks for an automobile manufacturer in Ingolstadt is being implemented. One of the tanks is a sludge storage tank for flocculated sludge, which is equipped with many attachments and agitator technology. In addition, two clean water tanks are supplied. All three tanks are constructed with a self-supporting stainless-steel roof.

Stainless steel tank with stainless steel floor

STAINLESS STEEL IS WORTH IT

The decision for stainless steel is always worthwhile: the follow-up costs for maintenance and repair are reduced to a minimum. At the same time, the lifespan of the Stallkamp stainless steel tanks is almost unrivalled. Stainless steel owes its resistance to corrosion to a simple chemical reaction: due to its chromium content, an ultra-thin chemically resistant passive layer forms on the surface in conjunction with oxygen in the air or water. If the passive layer is damaged by external influences, it will form a new layer from the matrix of the stainless steel. Unlike other materials or material combinations, stainless steel can be completely and easily recycled after use.

Wastewater tank with self-supporting ribbed dome roof

EVERYTHING FROM ONE SOURCE

In addition to high-quality stainless-steel tanks, Stallkamp also offers the associated pump and agitator technology. For special use in waste and clarification tanks, a full stainless-steel mixer is recommended, which is designed for stirring liquids with a variable pH value, generally from pH 5.3 to pH 8.1 at room temperature. The Stallkamp portfolio also includes separation technology, which is produced for a wide variety of applications and dry matter contents.

From May 14 through 18, Stallkamp will be exhibiting at IFAT in Munich, a world-leading trade fair for water, sewage, waste, and raw materials management, to promote the wastewater business. Exhibition devices and references will be presented at booth 208 in hall A1 and qualified consulting services will be offered.

Benjamin Budde serves as head of sales for Erich Stallkamp ESTA GmbH and can be reached at marketing@stallkamp.de. As a specialist for construction, production and assembling of high quality stainless steel products such as tanks, pumps, agitators and separators, Erich Stallkamp ESTA GmbH is the competent partner for almost every industry. Our variety of goods is successfully applied all over the world for forty five years in the agriculture sector as well as in the industry.

_______________________________________________________

MODERN PUMPING TODAY, March 2018

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!

![]()