For mechanical design of a fluid film bearing, the bearing designer must not only consider the proper sizing of the bearing to handle the loads and minimize the power loss but also incorporate features such as preload and offset that optimize the formation of film and tune the dynamic characteristics of the bearing. In the first half of this series, we examined the basic operating principle of hydrodynamic fluid film bearings and the selection of bearing materials. We conclude the series with a closer look at the options available in the mechanical design of the bearing, including the method by which lubricant is introduced and removed from the bearing, a factor that significantly affects bearing performance.

Taper land fixed profile thrust and tilt pad journal combination bearing.

BEARING DESIGN TOOLBOX

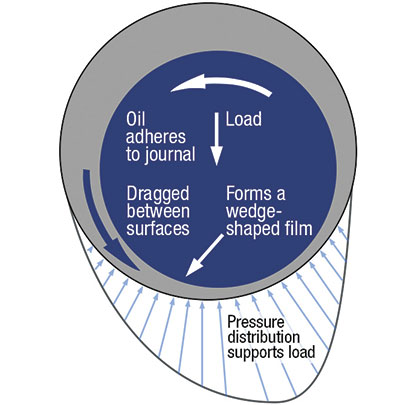

The formation of film is critical to the life and performance of a fluid film bearing. A viscous lubricant, the relative motion between the surfaces, and the converging geometry of the bearing are critical factors for the film’s development. Together, these create the pressure to counteract gravity and other forces operating on the shaft.

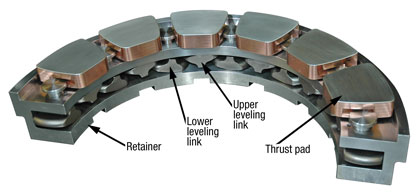

Although axial loads can be supported with flat bearing faces, typically a geometry is machined into the surface of a fixed profile thrust bearing to create a converging wedge and increase the bearing load capacity. A fixed geometry is designed for a specific condition; therefore, tilt pad thrust bearings are often used to accommodate changing conditions. Self-leveling tilt pad thrust bearings accommodate misalignment between the bearing and the collar by equalizing load between pads.

Self-leveling tilt pad thrust bearing to accommodate misalignment.

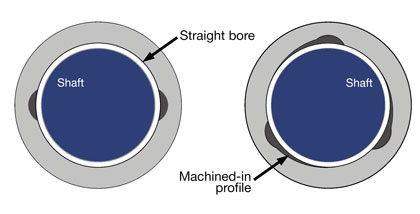

A journal bearing, due to the dissimilar diameters of the bearing and shaft, naturally has a converging wedge when the shaft is not centered in the bearing. For improved static and dynamic performance, a defined profile can be machined into the journal bearing to develop the proper film. If stability is still an issue, if varying conditions must be accommodated, or if other bearing performance parameters require optimization, journal tilt pads are often used.

Two of the many defined profile options for fixed geometry journal bearings: straight bore (left) and machined-in taper (right).

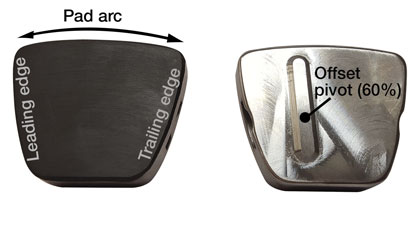

Thrust and journal bearings are sized to handle application load requirements and fit the given envelope. Other features can be optimized to achieve specific dynamic and static performance. Pad arc, the portion of the pad that develops pressure, can be adjusted to affect power loss and temperature. The offset, the distance from the leading edge to the pivot as compared to the pad arc, has a significant effect on the formation of the film and can impact bearing temperatures, power loss, and, in the case of journal bearings, dynamic performance.

Journal and thrust pads illustrating pad arc, leading and trailing edges, and offset pivots. The journal pad (left) is an integral rib tilt pad; the thrust pad (right) is a line pivot tilt pad.

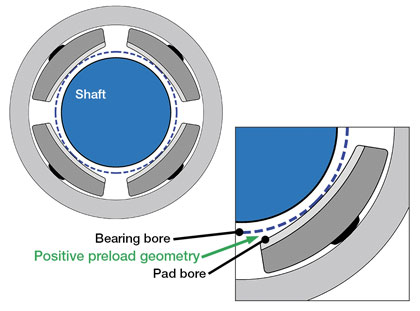

In tilt pad journal bearings specifically, temperatures, power loss, and dynamic performance can be greatly affected by the bearing clearance (the difference between the bearing bore and shaft diameter), by the length of the bearing, and by preload. Preload represents the deviation of the pad bore to the bearing bore. It can be positive (pad bore is greater than bearing bore), zero (pad and bearing bore are the same), or negative (pad bore is smaller than bearing bore). If the preload is positive, a converging wedge forms. A negative preload restricts flow into the pad and is not recommended.

An exaggerated view of positive preload geometry (applicable to journal bearings only).

On both journal and thrust tilt pad bearings, the pivot is selected based on specific needs, such as the required life of the pivot (stress), stiffness, and ease of pivot tilt in one or more directions. Common pivot types are point contact, line contact, ball and socket, and Flexure Pivot®. Each of these has distinct benefits. For example, the integral construction of the Flexure Pivot design’s pad and housing achieves tighter control of clearance and preload, as well as the desired tilt without pivot wear.

Flexure Pivot tilt pad journal bearing.

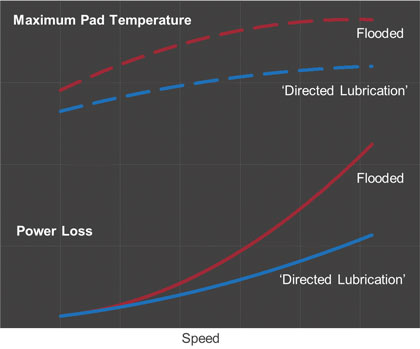

Another design option that significantly affects bearing performance is the method by which lubricant is introduced and removed from the bearing. By supplying lubricant to the leading edge of the tilt pad and allowing the lubricant to freely leave the bearing and its housing, ‘Directed Lubrication’ bearings operate with lower power losses and at lower operating temperatures than flooded bearings, where the lubricant is typically introduced into the bearing away from the film and flow out of the bearing is restricted. Flooded lubrication creates lubricant shearing outside the film that does not contribute to the load carrying capacity of the bearing.

Examples of trend lines for power loss and maximum pad temperature with flooded versus ‘Directed’ lubrication.

BRINGING IT ALL TOGETHER

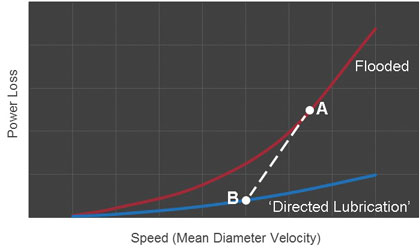

Combining select materials and design features will optimize performance further than either materials or design features on their own. For example, combining ‘Directed Lubrication’ with advanced material bearings—which are capable of handling thinner films, higher temperatures, and therefore, higher loads—can greatly reduce power loss compared to a flooded design with traditional bearing materials such as babbitt. Using advanced materials allows for a smaller bearing and lower viscosity fluid (even process fluid), thus reducing power loss. If power loss reduction is not required, a higher safety margin can be achieved.

Switching from a lightly loaded bearing with flooded lubrication (point A) to an optimized smaller bearing with ‘Directed Lubrication’ (point B) can significantly reduce power loss.

With the right material(s) and design, fluid film bearings can offer first-rate dynamic performance, low friction, minimal to no wear, and long life, making them the right choice to meet the demands of today’s process equipment. ◆

For More Information:

Barry J. Blair is chief engineer at Waukesha Bearings, headquartered in Pewaukee, Wisconsin. He has responsibilities for fluid film bearing research and development, including new products and the refinement of bearing design tools and methods. For more information, visit www.waukeshabearings.com.

____________________________________________

MODERN PUMPING TODAY, August 2016

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!

![]()