By Tom Korte, Rodem

A REVOLUTIONARY PUMPING TECHNOLOGY

Twin screw pumping technology has proven to be a viable alternative for transferring multiphase products, and it is designed to be capable of running at much higher speeds than conventional positive displacement pumps. For the sanitary market, Axiflow pumps set a new benchmark for a variety of pumping and mixing applications and offer viable solutions to many difficult processing problems often experienced with positive displacement pumps.

Keeping pace with twenty-first century consumer demand while maintaining operational costs and production schedules is trickier than ever. In today’s fast-paced society, food and beverage producers face rapidly changing consumer tastes, constantly emerging flavor trends and the demand for a variety of choices on supermarket shelves everywhere. As a result, these producers must find creative ways to incorporate flexibility into their processing systems and production lines, while adhering to tight operational budgets

and schedules.

To meet these ever-changing trends and high consumer expectations, savvy food producers leverage twin screw pumping technology to create the in-house flexibility their processes and consumers’ demand. The Axiflow twin-screw positive displacement pump has a non-contacting feed screw design, that facilitates a speed range of less than 50 and up to 4,000 rpm. This means that the Axiflow twin screw pump is able to process high-viscosity food products as well as low viscosity fluids like clean-in-place (CIP) solutions used for cleaning.

See how one Midwest yogurt producer was able to improve their flavor changeover process to meet customer demand, while controlling operating costs, improving efficiency, and eliminating downtime by incorporating twin screw pumping technology into their process for both product and CIP duties.

THE CHALLENGE

Prior to incorporating the twin screw technology, this producer was using manual swing connections to flush out between flavor changes in their yogurt process several times daily. Breaking the lines for flavor changeovers was negatively affecting production schedules due to the downtime necessary to disconnect, clean, and reconnect.

This producer faced other factors that contributed to unwanted downtime associated with manual connections and pump changes. For each flavor change, they needed manpower to manually break lines and make connections. The need to rely on manual labor also opened the door for other factors to impact production efficiency—from human error to safety concerns as operators navigate both over and under vessels to make the swing connections.

THE SOLUTION

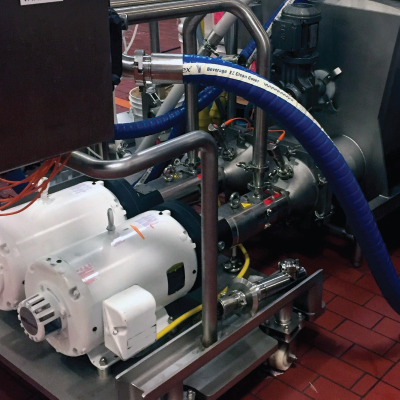

In order to meet consumer tastes and keep pace for production demands, this producer incorporated Axiflow twin screw pump technology into their yogurt process to serve as both process and CIP pump. On viscous products, twin screw pumps can run at a relatively low speed providing a gentle yet very high suction capability and extremely low, if any, pulsation.

On thin, water-like products, the Axiflow pump can be sped up to overcome the slip to maintain high velocities to perform CIP and CIP return pump functions. Since the cleaning medium flows completely through the pump at the required velocities, outstanding cleaning results are achieved. The pump is also cleaned successfully by CIP even under the most difficult operating conditions, as with viscous dairy products.

Because the Axiflow twin screw pump can perform double duty, both process and CIP, they were able to eliminate the need to break lines and do manual swing connections to flush out between flavor changes, enabling greater uptime for production.

When it is time to clean between flavors, they simply ramp up the Axiflow pump that is also being used for process and are able to flush the lines and pump out water flush from process vessels without switching to another pump. This has also done away with the need to have a separate CIP pump to purchase, maintain, control, and operate.

THE RESULT

The elimination of manual swing connections results in less downtime and more up time to meet production goals. With the number of flavor changes daily, the ability of the Axiflow pump to perform both process duty on viscous products and overcome slip on thin products like CIP has significantly increased process efficiency.

The result is faster processing from one flavor to the next, coupled with a variety of other benefits that accompany incorporating twin screw pump technology into their process. In addition to the boosted productivity, this producer has utilized Axiflow twin screw pump technology to:

- Eliminate product-to-product carryover

- Decrease labor expense due to the elimination of manual line breaking

- Improve pump performance from human errors or manual mistakes

- Improve operator safety

- Ensure product quality through minimizing contamination risks that are present during manual line breaking

The Axiflow pump does have a higher initial cost than traditional pump alternatives, but it makes up for that with an extremely low cost and simplicity of ownership. Because one pump performs two duties, spare parts and maintenance needs are simplified and there is no need for duplicate pump controls. Axiflow twin screw pumps can operate in the field for years before requiring any spare parts.

Faster processing, boosted productivity, improved safety, the added flexibility through Axiflow twin screw pump technology helped this yogurt producer maintain the uptime required to keep up with their production schedule and meet the rapidly changing consumer demands of the twenty-first century.

FOR MORE INFORMATION

Tom Korte is director of sales for Rodem. 2021 marks Rodem’s fiftieth year in business in the sanitary processing industry. Rodem credits its success to a talented workforce, loyal customers, dedicated partners, and the drive to provide valued clients with the best possible solutions and service. For more information, visit

www.rodem.com.

MODERN PUMPING TODAY, September 2021

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!