When locals are asked to describe the sweeping landscape of West Texas, some smile and offer, “It’s like Mars . . . but near New Mexico.” However, this rocky and open terrain is far from barren. Just as oil fields have become synonymous with boom towns like Houston and Dallas, other parts of Texas are striking out for alternative sources of energy. With miles and miles of exposed territory, West Texas is an optimal wind farm location and, in the coming years, more of their sleek turbines can be seen dotting the horizon.

The Department of Energy (DOE), Sandia National Laboratories (SNL), National Wind Institute of Texas Tech University (NWI/TTU), and Group NIRE (NIRE) formally commissioned the Scaled Wind Farm Technology (SWiFT) test facility in Lubbock, Texas. ABB’s solutions in the turbines included three ACS800 wind converters and three matching Baldor induction generators, and earned recognition for improving the wind farm’s performance.

SWIFT AND SURE

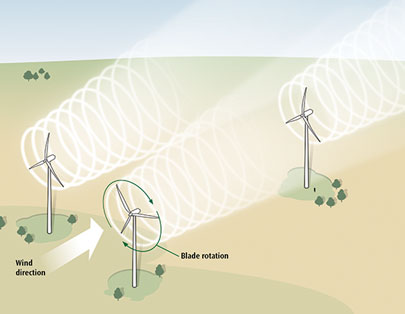

The SWiFT facility is the first public facility of its kind in the world to use multiple wind turbines to measure how wind turbines generate turbulence and how that airflow disruption affects the performance and reliability of other turbines in a wind farm. This testing allows research and collecting data on new turbine blade designs, the flow of wind through and past the wind farm, and on the equipment inside the nacelle. The project retrofitted three older, fixed speed Vestas V27 turbines with ABB’s latest technology, turning them into scientific instruments.

SWiFT’s primary research objectives are to

- reduce power loss and damage caused by turbine–turbine interaction through study of complex wake flows through study of complex wake flows;

- enhance wind farm energy capture and damage-mitigation potential of advanced rotors;

- improve the validity of aerodynamic, aero-elastic, and aeroacoustic simulations used to develop innovative technologies; and

- improve wind plant reliability with new technology.

The turbines are heavily instrumented with state-of-the-art control and data-acquisition systems featuring GPS-based, sitewide time synchronization. The site instrumentation provides hundreds of channels of structural and aerodynamic data to fully understand the instantaneous state of the rotor, wind turbines, and wind farm for advanced control strategies, such as rotor-based active aerodynamic load control.

EARNING RECOGNITION

The facility construction included the raising of the three towers and turbines over the course of several weeks. The retrofitted wind turbine served as backdrop for the commissioning event where Kent Hance, Chancellor of the Texas Tech University System spoke to the group. The turbines contain ABB wind converter and Baldor induction generator technology. A tower on site measures wind velocity, while Doppler Radar domes will further serve to study how wind conditions affect the turbine performance.

ABB was invited to attend the special event and was recognized as among the companies that provided key equipment to the facility. Bob Simon, product manager for ABB’s Renewables Power Conversion business, and Marty Mates, Baldor’s industry account manager for power generation, both attended the commissioning.

“ABB’s advanced generator and converter technology allows each turbine to operate at variable speeds and still be connected to the electrical grid,” explains Simon. “This flexibility allows for a larger data set to be gathered during testing, and a full speed range analysis performed on the turbine blades.”

WHERE THE WIND IS BLOWING

By accumulating and analyzing this data, the business, government and non-profit groups supporting SWiFT aim to reduce power loss and equipment damage caused by turbine–turbine interaction. This equates to enhanced wind farm energy capture and further improves wind plant performance, industry-wide.

Rising energy costs, increasing global demand, and greater awareness of environmental responsibilities have made wind farms a rising star for alternative energy proponents. As more energy consumers come to rely on wind energy, the data collected as SWiFT and other research facilities will be the basis for the next generation of production and capture. However those facilities of the future make use of technology, their roots were planted in the soil of West Texas. ■

_________________________________________________________________________

ABOUT THE AUTHOR

Ken J. Graber is the marketing communications manager for ABB Inc.—a leader in power and automation technologies that enable utility and industry customers to improve their performance while lowering environmental impact. He can be reached at ken.j.graber@us.abb.com. For more information about ABB, visit www.abb.com.

_________________________________________________________________________

MODERN PUMPING TODAY, August 2013

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!

![]()