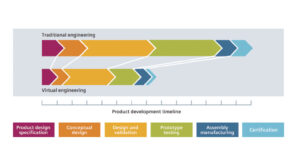

Frontloading computational fluid dynamics benefits everyone: Part 2 of 2

see Part 1 here

The benefits of simulating early as a part of the design process have been documented extensively. The cost of each engineering...

How Vibration Monitoring and Preventive Maintenance Increase Efficiency

In most scenarios, preventive maintenance is a more cost- and time-effective solution to increase efficiency rather than waiting for it to fail and having...

Acorns, User Experience, and Optimization

Along the Tampa Riverwalk, while attending the Electrical Apparatus Service Association (EASA) convention, I saw the following quote from Ralph Waldo Emerson: “The creation...

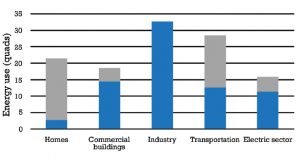

Energy Efficiency and Corporate Sustainability

By Lowell Ungar and Andrew Whitlock, ACEEE

Many U.S. companies are taking steps to reduce their impact on the environment, and especially on climate change,...

Controlling Dangerous Dusts in the Chemical Processing Industry: Part 1 of...

By David Steil, Camfil Air Pollution Control

Effectively controlling toxic and combustible dust generated in chemical processing facilities is essential to protecting employee health, maintaining...

Repair, Rehab, Reimagine

Technological advancements are constantly providing better, faster, and safer solutions to the industry’s most challenging obstacles. Quickflange™ is a unique technology that specializes in...

Taking the Heat at Arkansas Sawmill: Part 2 of 2

Modern sawmills are a far cry from their early predecessors, although the basic need for lumber has not changed. Today’s sawmills are massive, sophisticated...

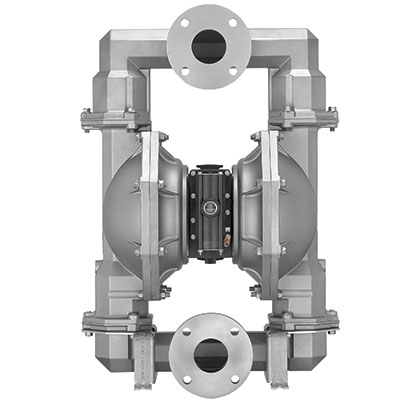

The Proper Pump, Maintenance, and Air Line Accessories Mitigate Problems Caused...

Pump operators should use filters and regulators when needed to condition the air supply. This encourages more reliable pump performance and reduces equipment wear...

Come Hail or High Water: Part 1 of 2

Whether it’s wildfires, hurricanes, or hail, natural disasters devastate solar power infrastructure. Particularly for asset owners of utility PV, extreme weather can cause significant...

Safety controller simplifies designs

Machine safety will always be a concern across myriad fields in the industrial sector. However, despite technological advances and careful regulatory oversight, some operators...