By Roger Ingemey, Circor

When process operations depend on 100 percent running time, control valve actuators must offer unrivaled performance together with low maintenance requirements. Ideal for processes that depend on these conditions in multiple industries—including industrial, chemical, and power applications—Circor International’s RTK® REact EQ-L electric intelligent linear actuators are built for high-range force output. Corrosion-resistant variants have been specially designed for offshore applications. The REact EQ-L electric actuator offers an all-in-one intelligent package for applications with opening/closing forces from 3,380 pound-force up to 6,750 pound-force.

REPLACING THE OLD SCHOOL WITH INNOVATION

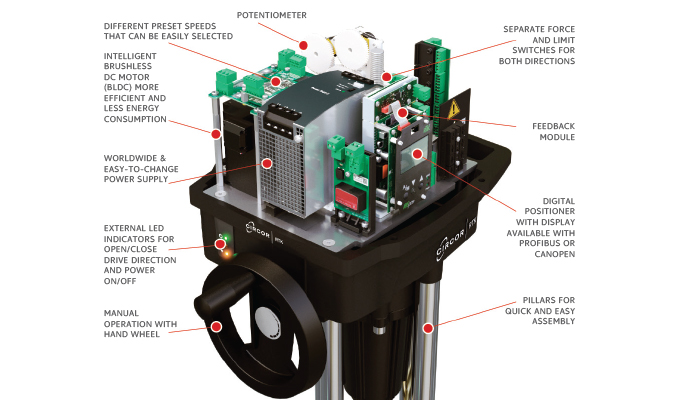

RTK REact EQ-L offers system-protecting functions for medium-to-heavy applications with higher pressure drops or large or unbalanced valve trims. The new actuator makes it easy to replace old-school synchronous drive technology for industrial, chemical, power, and process actuation requirements. Using the newest brushless DC (BLDC) motor system, REact EQ-L offers high force and delivers up to 60 percent energy savings compared to synchronous drives.

Other cost-saving features include over-force protection to prevent damage to the valve and actuator; reduction in maintenance due to 100 percent running time; and external LEDs indicating actuating direction for easy monitoring. Also included is a smart controller with several adjustable and easily selectable preset speeds.

AT-A-GLANCE SYSTEM STATUS

REact EQ-L’s external LED clearly displays operating directions and power status for easy monitoring. Outfitted with RTK’s optimized REpos digital positioner, this actuator offers data logging functions and the possibility for remote control through Profibus or CANopen. Using field device notification of diagnostic status, users can expect to conduct timely, status-based intervention to promote higher system availability and reduced maintenance costs.

The new REact EQ-L opens the door for Industry 4.0 functionality and flexibility for multiple signal exchange systems in open digital protocols for process automation. REact EQ-L is also programmed with over force limiting technology to protect the valve and actuator, allowing the motor to self-regulate and serve as a built-in safety feature. Unlike other electric actuators, it works to help ensure 100 percent running time, 24/7.

SAY GOODBYE TO COSTLY SURPRISES

Approved for protection rating IP 66 and NEMA 4x, CE design and NRTL certification, REact EQ-L’s single gear unit-motor combination offers three different open/close force outputs; easy setup for worldwide voltage inputs and actuator protocols; and different speeds for different applications with only one gearbox.

When force outputs are high, keep damages to valve parts and actuators low with RTK’s REact EQ-L. It’s an innovative system-protecting solution that combines RTK’s signature modular design with more efficient, adaptable, and connected actuator technology.

FOR MORE INFORMATION

Roger Ingemey is vice-president for power and process at Circor International, Inc. Circor RTK is an international leader in the design, manufacture, distribution, and service of control valves and related equipment. In its fourth decade, the company continues to engineer innovative and reliable control technology for optimization of customer control circuits. RTK produces high-quality control and shut off valves ideal for industrial, process, petrochemical, and power applications. It also offers effective electric and pneumatic linear actuators, sensors, and controllers. For more information, visit www.circor.com/rtk.

MODERN PUMPING TODAY, October 2021

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!