The oil and gas industry is increasingly relying on electromagnetic flowmeters, commonly known as magmeters, as a crucial tool to address the ever-growing challenges of managing produced water—the water that is brought to the surface during oil and gas extraction operations. Not only is the volume of produced water surging, but at the same time, the industry faces mounting constraints on its use and disposal.

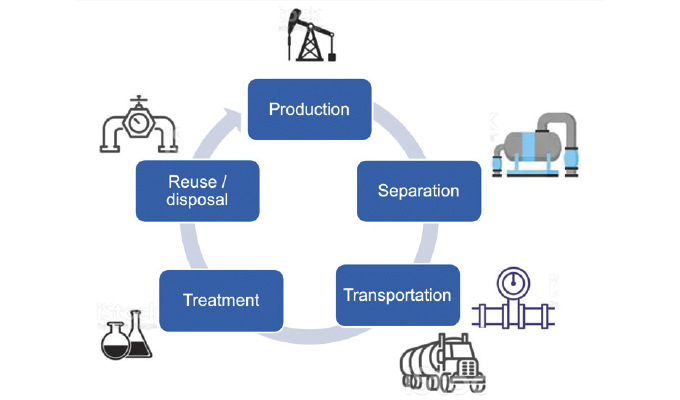

These growing financial and environmental pressures have heightened the importance of accurate and reliable measurement of produced water flow at every stage—from extraction and separation to transportation, treatment, and eventual re-use or disposal. Consequently, the industry is transitioning from conventional mechanical meters to intelligent electromagnetic flowmeters, enabling more efficient and effective management of produced water.

SURGING VOLUME OF PRODUCED WATER

The dramatic growth in the volume of produced water in North America follows the overall expansion of oil and gas extraction activities. As global energy demands intensify, the industry continuously seeks out new reserves and employs methods to tap into previously inaccessible oil and gas fields.

Extraction methods now include the exploitation of unconventional reserves such as shale formations, which often involve hydraulic fracturing or fracking. This process requires large volumes of water to fracture the shale rock and release hydrocarbons, leading to a significant increase in the quantity of water that needs to be managed after the extraction process.

Another important factor contributing to the rise is that as fields mature, more water is produced for each volume of oil or gas extracted.

CHANGING PERSPECTIVES

Previously considered an inconvenient byproduct, produced water has begun to be recognized as a critical component of the industry’s operations. This evolving view of produced water in part reflects a broader shift toward a more sustainable and circular economy approach within the oil and gas industry.

Advances in technology enable more effective treatment and use of produced water, potentially transforming it from a cost center to a potential asset. Some companies are exploring innovative ways to convert the water’s constituents into valuable products or for reuse in operational processes.

Increasingly, in the USA and elsewhere around the world, federal, state or local governments endeavor to effectively manage produced water to safeguard surface and groundwater resources while alleviating the future demand for fresh water. By pursuing the pollution prevention hierarchy of “Reduce, Reuse, and Recycle,” the industry is exploring traditional and innovative approaches including the reuse of treated produced water for irrigation of non-edible agriculture, such as cotton or biofuel crops.

In addition to protecting freshwater resources, regulators seek to mitigate seismicity risks by imposing stringent production limits and requiring strict monitoring and precise measurement of the water injected as part of the oil and gas extraction process since it has been determined that reinjection of water can exert stress on fault lines and potentially cause earthquakes.

METICULOUS MONITORING

Therefore, accurate measurement of water is crucial at every stage. The quantities must be reconciled to ensure no loss occurs at any point of the process. This meticulous monitoring helps maintain water integrity and sustainability throughout its lifecycle.

Moreover, accurate flow measurement is essential for controlling costs and ensuring optimal operational efficiency. This is particularly evident in the transportation and treatment of produced water. Transportation, especially when done by truck, represents a significant expense and requires effective flow management. The treatment of produced water, removing the cocktail of organic and inorganic compounds, also necessitates precise flow measurement to maintain cost-efficiency and operational effectiveness.

MAGMETERS: IDEAL FOR MEASURING PRODUCED WATER

The operational principle of electromagnetic flowmeters makes them particularly well-suited to flow measurement in produced water applications in the oil and gas industry due to the saline nature of the water.

Magmeters function based on Faraday’s Law of electromagnetic induction, where the voltage induced is directly proportional to the speed of the fluid, the magnetic field’s strength, and the length of the conductor. In a magmeter, the salty water serves as the conductor. Since produced water is high in salinity, it enhances the electrical conductivity of the water, leading to highly accurate measurement.

Moreover, the non-intrusive design of magmeters enables them to operate efficiently even in corrosive saline water environments, without experiencing degradation. As a result, they provide a cost-effective and dependable solution for managing and monitoring produced water systems.

A LOOK AHEAD

Next month, we’ll walk through some of the details for and benefits of transitioning from mechanical flowmeters. Not only do magmeters offer higher accuracy, more reliability, and ease of maintenance, but they also open the door for smart meter capabilities that include leak detection, online diagnostics, and data collection and analytics. Lastly, we’ll also include a quick guide for selecting the right magmeter for your application needs.

Ron Garcia is strategic business director for Krohne, a world-leading manufacturer and supplier of solutions in industrial process instrumentation. Krohne offers supporting products and services for one-stop-shopping and in industries as widespread as oil and gas, water and wastewater, chemical and petrochemical, food and beverage, power, minerals, and mining and marine. For more information, visit www.krohne.com.