Since over 80 percent of electrical maintenance testing involves evaluating insulation integrity, Insulation Resistance Testing (IR) is a very important test. This is because electrical insulation begins to age as soon as it’s manufactured and aging causes deterioration in the performance of the insulation. Harsh operating environments will also cause further deterioration, especially where the electrical insulation is exposed to extreme operating temperatures, moisture, and chemical contamination. As a result, personnel safety and operating reliability can both be compromised. It’s extremely critical to always know the electrical condition (IR) of the insulation in your equipment at all times.

WHAT IS AN INSULATION RESISTANCE TEST?

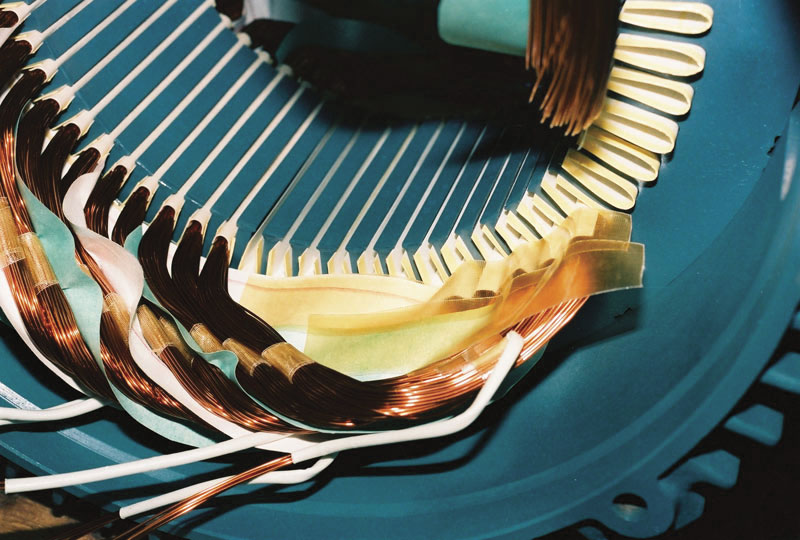

The Insulation Resistance (IR) test, commonly known as a “Megger” test, is normally used as a “Spot type” test to measure the insulation’s dielectric condition at a given moment in time. The test is performed by applying a current limited DC test voltage between the conductors (Windings) and the chassis of the equipment (Ground), and then measuring any current leakage across the insulation’s dielectric materials. The current may be measured in Milli-amps or Micro-amps and then calculated into Meg-ohms of resistance. The lower the current level measured, the greater the insulation resistance.

The Insulation Resistance test is always the first test performed before doing any other type of electrical testing on equipment. The IR test results are critical in first determining if the insulation will be able to withstand any other type of electrical testing, such as Hi-pot or Surge testing. If the equipment does not pass the IR test, then no further testing should be done until the problem is corrected. In order to perform a “True” IR test on electrical equipment, the equipment always needs to be offline and isolated from the input power source.

USING THE CORRECT DC TEST VOLTAGES FOR IR TESTING:

A critical component of the IR test itself is the DC test voltage level used during the process. The amount of leakage current that can be measured in an insulation’s dielectric material is directly dependent on the test voltage level being applied. IEEE, NETA, and ABS standards all confirm that when performing an IR test, the higher the test voltage level used the greater the ability will be to detect any defects that may be present in the insulation materials. Those defects, such as dirt or moisture, are what breakdown the insulation materials causing the insulation resistance to drop to an unacceptable level and eventually making the equipment unsafe to operate. Typically, a 500 VDC or 1000 VDC test voltage is used for low voltage equipment and either a 2500 VDC or 5000 VDC test voltage is used for medium and high voltage equipment. IEEE Std.43-2000 and NETA MTS-2011 both contain industry standard guidelines for choosing the correct minimum test voltage to be used when performing IR testing on equipment operating at various voltage levels. These minimum IR testing voltages must always be adhered to in order to accurately measure the Insulation Resistance in all electrical equipment. Any test done at a lower test voltage level is considered to be inaccurate and misleading at best.

UNDERSTANDING THE IR TESTING RESULTS:

The IR test measurement obtained is intended to indicate the integrity of the electrical insulation, whereas the higher the IR level the better the condition of the insulation. Ideally, an IR test reading should be at an infinite level. However, since no insulators are perfect and leakage currents will flow through the dielectric material, between the conductive parts, it ensures that a finite resistance value can be measured. When performing IR testing there are generally three types of current flow detected. It is important to understand all three types of current and how they affect the IR readings:

- Capacitive Charging current is the current that flows upon application of the DC voltage to charge the capacitance between the insulation system under test and earth. This current level will be high in the first instance before dropping off quickly to zero as the capacitor is charged (i.e. within 1 second).

- Dielectric Absorption current is the polarizing current that is drawn by the insulation system to align the dipoles within the dielectric material, with the applied electric field. This current level is high initially but then gradually drops off as the dipoles in the insulation become increasingly polarized (i.e. on the order of 10 minutes to hours).

- Leakage current is the resistive current that continuously flows through the insulation to ground via any leakage paths that may exist in the dielectric materials. Obviously, a low leakage current level implies that an insulation system is in good condition. The leakage current level should also stay more or less constant over time in good insulation materials.

While it can be useful to monitor all three types of current during IR testing, both the Leakage current and Dielectric Absorption current are the two measurements that are most commonly used in evaluating the insulation’s overall integrity. However, the Capacitive charging current measurement is also a useful indication of the age and performance of the insulation’s dielectric materials. It is very difficult to detect that type of current unless you are using a permanently installed automatic (PIA) IR testing system to test the equipment. That’s because the capacitive charging current causes the IR reading to initially be very low and then it will quickly rise to a higher reading within seconds. This occurrence indicates that the insulation is in good condition and the operating life expectancy is also good. If the IR reading were to drop immediately to a very low level and then not quickly raise up higher, it would indicate that the insulation is aging and the operating life left has been diminished due to defects in the insulation materials.

The Dielectric Absorption or Polarization current measurement is time dependent, because the current decreases slowly over time while the DC test voltage is being applied. This type of current measurement is commonly referred to as a Dielectric Absorption Ratio (DAR) or Polarization Index (PI) ratio test. When performing these tests, the IR reading is used to create a ratio between a 30 second and a 60 second IR reading for the DAR test, or a one minute and a ten-minute IR reading for the P.I. test. A minimum ratio of (1.6) for the DAR test or a minimum ratio of (3) for the PI test indicates that the insulation is in acceptable condition. Any ratio less than these minimum values indicates that there are parallel leakage paths through the insulating materials which indicates that there is a problem. The most common cause of insulation degradation is surface moisture on the dielectric insulation materials. The moisture creates parallel leakage paths to ground through cracks or defects in the insulation materials. These tests are very useful in determining the present “Real Time” electrical condition of the insulation materials.

The Leakage current measurement is the most commonly used value to indicate the overall dielectric condition of the insulation, and is the current being measured during an IR test. Leakage current is time and frequency dependent, which means the number of tests performed and the duration of time that the testing is performed affects the testing results. Ideally, the IR test reading should increase slowly over time and then maintain a stable consistent level. This type of test, when done manually, is typically performed as a “spot type” test and is affected by the ambient temperature of the insulation at the time of the test. The IR reading then requires a temperature conversion to obtain the true leakage current at that time.

However, with the new style permanently installed automatic (PIA) type of IR testers, the leakage current testing is done continuously over long periods of time. The numerous test results then become averaged over time, resulting in leakage current readings that are therefore temperature independent, meaning these IR readings do not require a temperature correction and the resulting value is the “True” leakage current of the insulation. A low IR leakage current reading that is maintained over a long period of time and does not fluctuate is, in theory, in acceptable condition, even if the IR reading is below the recommended minimum safe level as outlined in IEEE Standard 43-2000. An IR test reading that begins at a high level and then has a significant decrease over time is then considered to be unacceptable and an indication of defects in the insulation. An IR test reading that begins at a low level and then slowly rises to a level greater than four times the initial level, indicates that the insulation is in new or excellent operating condition. The new method of permanently installed automatic (PIA) IR testing is far more accurate and has become a more reliable method of determining the “true” IR leakage current in the insulation.

A LOOK AHEAD

In the following two installments of this series, we will dive deep into the problems with manual IR testing along with the advantages of permanently installed automatic (PIA) IR testing equipment. The conclusion of this series will specifically focus on the effects of long term continuous IR testing on electrical equipment and their benefits. ◆

Richard J. Zelm is vice president of engineering at MegAlert, Inc. MegAlert is committed to making the workplace safer and more innovative than ever before. With over three decades of experience in the process control instruments industry, customers count on MegAlert to provide high-quality products and excellent service. For more information, visit www.megalert.com.

____________________________________________

MODERN PUMPING TODAY, August 2017

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!

![]()