Following the acquisition of natural gas production rights off the northern coast of Mozambique by a French oil company, modules to avoid hydrate formation needed to be set up for compression of the gas and its later conversion into LNG (liquefied natural gas). The MEG (mono-ethylene glycol) used for this purpose is injected directly at the delivery line under the sea. The company needed powerful pumps that could transport the MEG from the coast to the offshore units. The main challenge was to achieve a sufficiently high flow rate despite the high back pressure in the pipes. At the same time, maintenance work was not to lead to interruptions in production, as this would have resulted in heavy financial losses.

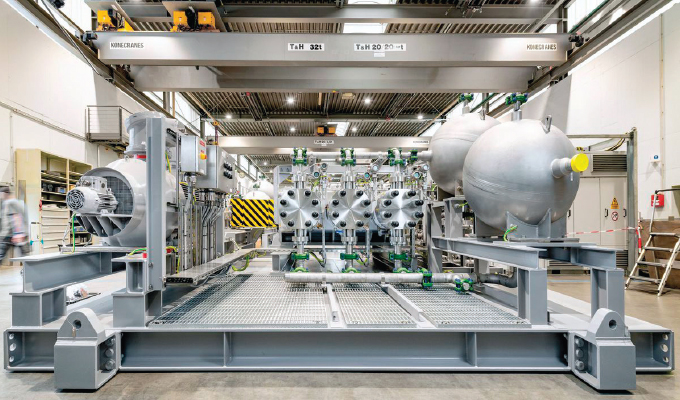

Due to its internationally renowned expertise in the oil and gas sector, LEWA Nikkiso America Inc., a subsidiary of German LEWA GmbH, was awarded the contract in November 2019. Six G3U triplex pumps were chosen because they are specially designed for the high-pressure range of over 500 bar. By using the M800 pump head, this model enables a flow rate of 635 cubic feet per hour per pump. Two of the six pumps are kept on stand-by for maintenance or repair work. The pumps are manufactured at the main Leonberg, Germany plant, and the base plates and resonators are supplied by LEWA Nikkiso Middle East.

GREAT CARE NEEDED IN UNPREDICTABLE CONDITIONS

When natural gas is extracted at sea, adverse weather conditions, rough seas, and high pressure under water must be taken into account, and the quality of the extracted raw material must be ensured. Natural gas contains water, which in combination with methane can form methane hydrate. This is done under high pressure and low temperature in the pipeline. If too much hydrate is formed, the pipeline can become clogged—to prevent this, glycol is injected. MEG functions here in a similar way to antifreeze. Glycol injection is also necessary in a French mineral oil group’s current project. Since acquiring production rights off the north coast of Mozambique, the group has begun preparations for extensive LNG production.

Since the offshore units through which the natural gas is produced are not located on a platform but underwater, the glycol is pumped from the coast via pipelines directly to the production sites. LEWA Nikkiso America Inc. was commissioned to provide the pumps required for this purpose. It is a subsidiary of LEWA GmbH, which is known for its expertise and has been active in this field for over sixty years. For the time being, two of a total of seven planned production trains were to be equipped with process diaphragm pumps.

The biggest challenge in this project is certainly the combination of high back pressure from the production site and the large amount of monoethylene glycol required, which has to be conveyed to the well around the clock. The MEG must be injected continuously despite this pressure. At the same time, we have to ensure that the pumps are 100 percent reliable so that even maintenance does not lead to an interruption in the gas drying process and thus to a costly delay of the entire pumping process. Last but not least, the aggregates should function as economically as possible.

A POWERFUL, STABLE SOLUTION

To counter these problems, the responsible persons at LEWA decided to use the proven triplex pump with pump heads specially modified for this application. The G3U variant in combination with the M800 pump head enables a flow rate of 635 cubic feet per hour per pump, despite the high back pressure of 517 barg. A total of three pumps will be installed per production train, with one pump being kept available as a stand-by unit. On the one hand, this results in a flow rate of about 1,270 cubic feet per hour MEG and on the other hand, the reserve pump can step in if maintenance work has to be carried out on one of the other pumps. Reliable, constant injection is thus ensured and interruption of natural gas production is largely excluded.

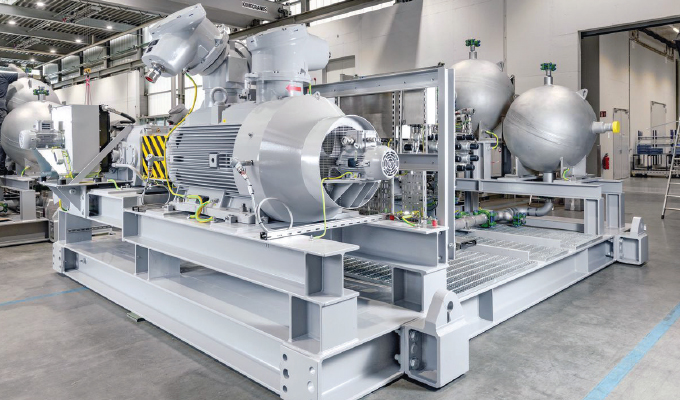

The pump heads are special models that can also work with a PTFE sandwich diaphragm, thanks to a diaphragm clamping system designed for high pressures. Comparable pumps must otherwise be equipped with a metal diaphragm to withstand the high pressure. However, for design reasons, such diaphragms are hardly feasible in the size for the drive unit used in this power class.

At the same time, the pump head takes up less space and is more compact than models with the stiffer metal diaphragm, which would require a much larger diaphragm diameter for the same degree of displacement. This would automatically lead to a larger pump head diameter. In order to reduce pulsation and avoid vibration-induced damage, resonators are also used to ensure that the medium flows evenly. Like the base plates, they are manufactured at the LEWA Nikkiso Middle East plant in Sharjah, United Arab Emirates. The final assembly, including the piping, took place in Leonberg.

LOOKING TO THE FUTURE

After the first three pumps were successfully accepted by the customer and the operator with a final acceptance test (FAT) in October 2020, this was also done for the second pump delivery in December. FATs are required by the operator for such big equipment to ensure that there are no surprises on site. The first three pumps were sent out in November of that year. The second delivery has also been packed and shipped to our customer in the United States. Our customer installed the pumps in larger modules and then shipped the completed modules to Mozambique.

FOR MORE INFORMATION

LEWA develops technologies and provides solutions for the vast array of applications among its customers. Its products are used mainly in the oil and gas industry, in gas odorization, in refineries and petrochemicals, as well as in the production of plastics, detergents, and cleaners. Additional application areas include the chemical industry, cosmetics industry, pharmaceuticals and biotechnology, food and beverage industry, and energy utilities. For more information, visit www.lewa.com/en/applications/gas-drying-with-glycol.

MODERN PUMPING TODAY, January 2022

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!