By Rob Martindale, Watson-Marlow Fluid Technology Group

Last month, we stressed that the importance of water and the impact of mining on local and regional water quantity and quality cannot be underestimated, and consequently all mines must carefully choose the pump equipment and systems they will use. In a peristaltic pump, such as a Bredel hose pump, nothing but the hose touches the fluid, eliminating the fluid contaminating the pump. The hose is at the heart of peristaltic operations, and in the following conclusion to this article, we’ll highlight its benefits as well as calculate savings of using a peristaltic hose pump over a rubber lined centrifugal pump.

THE HEART OF PERISTALTIC OPERATIONS

Fluid is drawn in and trapped between two shoes before being expelled. The complete closure of the hose, which is squeezed between a shoe and the track, gives the pump its positive displacement action. The result is a pump ideally suited for the transport of typical mining slurries including pyrite, copper, zinc, uranium, nickel, cobalt, silver, platinum, lime, and gold concentrate.

Pumps like the Bredel range are virtually maintenance-free as there are no impellers, liners, or mechanical seals to replace, no check valves to clog, and no rotors or stators to wear out. The only wear-part is the hose, which can be replaced in a matter of minutes with no special tools.

The hose is the secret at the center of peristaltic technology. This is the part in direct contact with the slurry—so it needs to be both flexible and tough. At the heart of all Bredel hose pumps is a composite hose constructed from compounded rubbers reinforced with four individual layers of braided nylon, and finished by precision machining for enhanced suction, pressure and flow performance over its expected lifetime.

Design features such as these are important because over-occlusion of the hose stresses both the pump and hose, reduces hose life, and places unplanned loads on the pump bearings. Similarly, under-occlusion results in loss of pump efficiency and damaging back-flow, which also reduces hose life.

CALCULATING THE BENEFITS

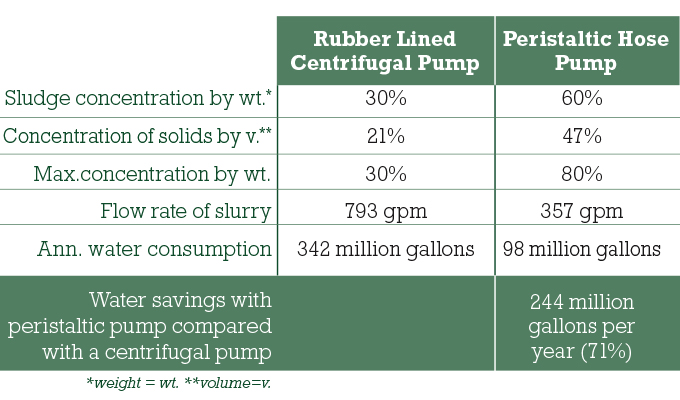

In a thickener underflow application, consider an example of copper extraction based on froth flotation. Using a hose pump, higher slurry densities can be achieved compared to centrifugal alternatives. This ultimately introduces savings against process water and filtration equipment.

A typical slurry density goes up to a maximum of 194 pounds per cubic foot: Based on 35 cubic feet of slurry, and assuming that the ore is chalcopyrite (CuFeS2) at a density of 268 pounds per cubic foot, it is possible to calculate volumetric solid content of 63 percent.

Based on published data for centrifugal pumps, it is known that the maximum dry solid content (by weight) will be 27 to 29 percent before efficiency begins to drop. Thus, assuming a maximum dry solid content of 30 percent by weight for a centrifugal pump, it can be shown that for the transfer of 70 tons of ore per hour (for example), a centrifugal pump will require a flow rate capacity of 6,390 cubic feet per hour, some seven times greater than that of a Bredel 100 to perform the same task, which offers 918 cubic feet per hour.

ANNUAL WATER USAGE: PERISTALTIC COMPARED TO CENTRIFUGAL PUMP

EVIDENCE OF GROWING UPTAKE

More and more mining industry customers are turning to peristaltic technology to provide solutions to specific problems. This is because peristaltic pumps can help mine operators face up to key challenges, which include:

- Reducing downtime

- Reducing operating costs

- Meeting environmental regulations

- Managing and reducing water inventories

- Reducing chemical usage

- Lowering maintenance costs

One beneficiary of peristaltic technology is a large copper and gold mining company in Arizona that had to frequently replace components on hard chrome iron centrifugal pumps used in a difficult tailings slurry application. The pump impellers were wearing out every two weeks, causing significant downtime and costly repairs. The mine considered several different pump technologies, finally selecting Bredel 100 hose pumps. In this application, the hose pumps transfer tailings slurry almost 2,200 feet to a separate plant. With no seals to flush and the ability to pump tailings with a high solids concentration (80 percent) the mine uses much less water with Bredel hose pumps, achieving considerable savings in both maintenance costs and water usage. Another example can be seen at Jaguar Mining Inc., which operates four gold mines in Brazil. The company first adopted Bredel hose pumps at its Turmalina mine when it was faced with pumping paste backfill comprising 4 percent cement and 69 percent solids. No centrifugal pump could handle the task.

To overcome the challenge presented by paste backfill, the mine operator installed a Bredel 100 on a trial basis and the results were so impressive that it subsequently purchased the pump, which is now transferring the mix with an S.G. of 2.8 at a rate of 1,765 cubic feet per hour over a distance of 1,378 feet. Today, the Turmalina site has installed multiple Bredel hose pumps for applications including backfill operations, flotation processes, leaching processes, and working with reagents.

A similar success story at a large mine in New Brunswick, Canada, saw centrifugal slurry pumps replaced with Bredel hose pumps. The 65 percent solids of the zinc and lead thickener underflow slurries was too high to allow the centrifugal pumps to deliver the desired flow rate, while abrasive wear was causing an unacceptable frequency of costly repair. Because the abrasives in the slurry do not affect Bredel pump life, the mine is now able to minimize downtime and achieve reliability at the desired flow rate.

ACCURATE CHEMICAL METERING

Another potential area of saving is through accurate chemical metering. The range of chemicals used in mining processes is vast and includes copper sulphate, xanthate, SIBX/ MIBX, GUAR, cyanide, sulphuric acid, lime, flocculants, zinc sulphate, aerophine, sodium silicate, BIOX, surfactants, and sulphides to name but a few. However, by using microprocessor-controlled brushless DC drive technology, Bredel hose pumps will properly maintain the flotation rates of ore extracts to ensure economical use of expensive chemicals and create significant process efficiencies. Bredel hose pumps have become first choice in mines throughout the world for applications that include dosing process reagents and pumping shear-sensitive polymers for flocculation and coagulation, abrasive lime slurries for pH control, or corrosive chemicals like cyanide for gold recovery.

Ores, of course, have different mineral contents and pumps must consistently vary their dosing rates to optimize chemical usage and maintain plant throughput. Additionally, process reagents such as cyanides and acids are often highly corrosive but as the chemically resistive hose of a Bredel peristaltic pump is the only part in contact with the pumped product then there are no working parts exposed to the chemical.

The world’s largest trona soda ash mine in Wyoming was experiencing problems with its diaphragm metering pumps used for dosing flocculant into the trona processing lines. The diaphragm pumps would last only five to six months due to the highly corrosive nature of the flocculant. Even after trying to add large amounts of water to the flocculants, which subsequently had to be removed from the process, the diaphragm pumps would still fail.

The mine purchased several Bredel hose pumps to address pump maintenance and flocculant wastage problems. The hose pumps’ inherent corrosion resistance allows the mine to pump pure flocculant into the discharge lines and holding tanks. With no need to add water, the mine is saving money in water usage, process downtime, and maintenance costs.

CONCLUSION

Moving ores, concentrates, and residues in slurry form are essential parts of industrial mining processes. In an effort to reduce water, energy and chemical consumption, and improve slurry transportation reliability, more and more mining operators are discovering the simplicity and benefits of peristaltic hose pumps. With thousands of Bredel hose pumps already at work around the world, there is little doubt that hose pumps are the solution.

FOR MORE INFORMATION

Watson-Marlow Fluid Technology Group (WMFTG) is the world leader in niche peristaltic pump manufacture and associated fluid path technologies. Founded on nearly sixty years of supplying engineering and process expertise and with over one million pumps installed worldwide, WMFTG pumps are tried, tested, and proven to deliver. For more information, visit www.watson-marlow.com.

MODERN PUMPING TODAY, June 2020

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!