Electromagnetic flow meters, or “mag meters,” are the most widely used meter technology to measure the flow of water in the world today. As populations expand, water measurement and management is becoming increasingly critical to preserve our water resources. To complicate the equation further, many existing water treatment and distribution systems that need to upgrade their technology cannot shut down or stop service to the communities they serve. The result is unmetered lines or inaccurately metered systems which leads to costly water loss.

In 2011, McCrometer Inc., an innovator in flow measurement technology for over fifty-five years introduced the FPI MagTM electromagnetic flow meter. The FPI Mag promised to give the same specified accuracy of traditional “full bore” or “flanged” mag meters but with the ease of installation of insertion type meters. In addition, the FPI Mag promised to be “hot tapped” or installed while the system was running at normal capacity, preventing costly shut downs and the loss of service. While the hot tapped feature of the meter has been proven and documented in customer experiences, the third party proven testing had not previously been published. This paper will examine the accuracy claims for the FPI Mag and present testing performed. All testing presented in this paper was done at an independent third party test lab.

FPI MAG TEST PROTOCOL

The claimed accuracy for a calibrated FPI Mag meter is as follows:

- +/- 0.5 percent for Velocity 1 foot (0.3 meters) per second to 32 feet (9.8 meters) per second

- +/- 1.0 percent from 0.3 feet (0.1 meters) per second to 1 foot (0.3 meters) per second

Testing was done at Utah State Water Research Laboratory (USWRL) in Logan, Utah. USWRL was chosen to perform these tests because they are a well-known, reputable water lab and because they have a very large range of line sizes and flow rates they can achieve.

McCrometer chose to test the accuracy of a 30 inch (750 millimeter) FPI Mag at USWRL. This size was chosen instead of a smaller size due to the sheer volume of water a 30 inch (750 millimeter) line carries. In service, accuracy matters more in larger pipe sizes: in a smaller line in the 4 to 10 inch range, if the measurement is off by 1 percent at high flows, the meter would be off by a few hundred gallons, which represents a low cost in lost revenue. In a 30 inch line or larger, the amount of water flowing is much greater, so a 1 percent error can mean thousands of gallons of water unaccounted for, leading to significantly more lost revenue to the plant or district.

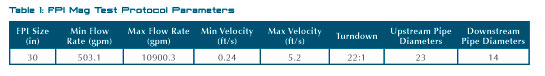

Testing was done over a wide 22:1 turndown with 23D upstream piping and 14D downstream piping. The long upstream and downstream pipe lengths simulate an infinite straight pipe section to establish the baseline performance of the meter without obstructions. Flow rates reported by the FPI Mag were compared against the flow rates reported by a 20 inch (508 millimeter) master Venturi flow meter owned by USWRL for the moderate and high flows. Flow rates reported by the FPI Mag were compared against a traditional 12 inch (304.8 millimeter) full bore mag master meter owned by USWRL for the low flow rates.

The complete detail of the accuracy test is found in table 1.

RESULTS

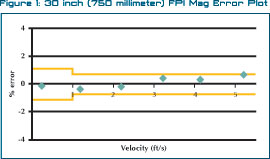

The results of the tests are best summarized in the accuracy plot below. The accuracy is expressed as the difference in the reading reported by the FPI Mag compared against the actual flow rate. The actual flow rate was established by the Venturi and full bore mag meter as described in figure 1. The orange bars represent the accuracy of the complete measurement system.

Tested accuracy of the 30 inch (750 millimeter) FPI Mag compared against the master flow meter is better than +/-1.0 percent for velocities between 0.3 feet (91 millimeters) per second to 1 foot (304.8 millimeters) per second. Tested accuracy above that was better than +/-0.5 percent within uncertainty of the system. For the test point at 5.2 feet per second, the tested FPI Mag accuracy was 0.66 percent. This is less than the total accuracy of measurement of 0.71 percent for the combined system.

Results of the 30 inch (750 millimeter) FPI Mag test prove the FPI Mag meets the accuracy claims. The measured error of the 30 inch (750 millimeter) meter was equal to or better than the specified accuracies for a wide range of flow. Not only was the meter accurate at low flow rates where accuracy is often difficult to achieve, but it was also very accurate at high flow rates where inaccuracy equals lost revenue.

We should highlight that two reference meters were necessary to measure the reference flow rate of one FPI Mag meter. In addition, one of the pipe systems had to be reduced from 30 inches (750 millimeters) inches to 20 inches (508 millimeters) to employ the Venturi, and again reduced to 12 inches (304.8 millimeters) to employ the full bore mag. Not only did the FPI Mag measure the full range of the Venturi and full bore mag, it did so without needing to reduce or change the pipe system. The FPI Mag allows operators to put the meter where they need it without making modifications to the piping system.

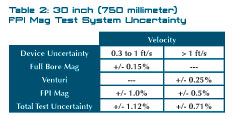

ACCURACY OF MEASUREMENT

When evaluating the accuracy of a flow meter, we must take into account the uncertainty of both the test meter and the system determining the actual flow rate. For the moderate and high flow rates of the 30 inch (750 millimeter) FPI Mag, the reported flow was compared against the flow rate of a USWRL Master Venturi flow meter. Venturi flow meters are a differential pressure type flow meter. Differential pressure (DP) type flow meters use a pressure drop across the primary element to determine a volumetric flow rate. The stated uncertainty of the Venturi master flow meter is +/-0.25 percent of flow rate.

For the low flows, the 30 inch (750 millimeter) FPI Mag was compared against the flow rate of a traditional full bore mag meter.

The stated accuracy of the full bore mag is +/-0.15 percent of flow rate.

SIMPLIFIED INSTALLATION AND SPEEDY SET-UP

Furthermore, the FPI Mag electromagnetic flow meter is easier than ever to install and set-up for use. With its precision multi-point flow sensing technology and efficient hot tap installation method, which eliminates the need for extra labor, heavy equipment, or line shut down, this next generation mag meter delivers superior performance, convenience and installation cost savings of up to 45 percent.

Now available with Quick Connect cabling, the FPI Mag flow meter’s set up process is simplified even further. The detachable Quick Connect Cable can be sent to the plant ahead of the sensor to allow for advance completion of wiring assembly work prior to sensor installation. Once the prep work is done, technicians can quickly install the sensing element without having to carry or manipulate extended lengths of heavy cable. Disconnect is also easy should the cable need to be removed from the sensor for maintenance or any reason.

The Quick Connect Cable for the FPI Mag flow meter is compliant with the International Electrotechnical Commission’s (IEC) IP68 standard. That means McCrometer customers can be assured the meter’s cable connection meets international requirements with regard to protection from both solid particles and liquid ingress. The durable cable connection is resistant to dust and water-tight to a depth of 3 feet (1 meter).

Unlike all other insertion mag meters, which only have a single point of measurement, the FPI Mag flow meter’s advanced multi-electrode sensor compensates for variable flow profiles including swirl and turbulent conditions. The electrodes, which are placed across the entire sensor body, continuously measure and report the average flow rate across the full diameter of the pipe, delivering accuracy comparable to the-performance of a full-bore mag meter.

Multi-point sensing technology makes the FPI Mag flow meter ideal in cramped plant retrofit equipment layouts or in confined space areas with limited straight pipe run availability. The sensor’s body also is hermetically sealed and protected by NSF certified 3M fusion-bonded epoxy coating.

Available for forward-flow only or a bi-directional measurement, the FPI Mag flow meter supports line sizes from 4 to 138 inches (101.6 millimeters to 3.5 meters). The flow sensor comes pre-calibrated from McCrometer’s NIST traceable Calibration Lab and requires no recalibration in the field.

The FPI Mag flow meter supports liquid flow measurement requirements in municipal water plant applications, including: distribution, wells and booster stations, disinfection dosing, filter balancing and backwash and effluent. Wastewater applications include effluent treatment and recycle/reclaim.

For industrial processes, the FPI Mag flow meter’s applications include: intake water, feed water, chilled water, cooling water, fire water, water recycling and effluent discharge. Such applications are found in diverse industries: chemical, electric power, food/beverage, oil/gas refining, metals/mining, pulp/paper and more, as well as chilled water and HVAC applications in large campus facilities. Given the ease of installation and the testing presented here, the FPI Mag meter is the next generation in water flow measurement. ■

ABOUT THE AUTHOR

Nicholas Voss is the product manager for the FPI Mag electromagnetic flow meter. McCrometer’s products and systems are found in thousands of installations worldwide and meet many of the world’s most demanding industrial, safety, and quality standards. For more information, visit www.mccrometer.com.

_________________________________________________________________________

MODERN PUMPING TODAY, February 2014

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!

![]()