As industrial communication has shifted from wired Ethernet to wireless RF and broadband connections, Digi International has led the way in addressing the technical hurdles many companies face in this new arena. Aaron McNally, a market development manager at Digi International, spoke with Modern Pumping Today about the challenges, changes, and advantages of wireless industrial communication systems.

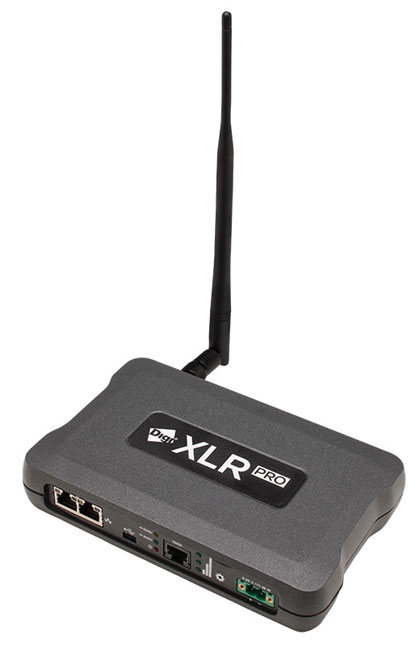

Modern Pumping Today: At many remote sites, users are looking to send huge amounts of field data over long distances. How do wireless data transmitters like Digi’s XLR PROTM help fill that need?

Aaron McNally: First, any time you have a wired line—especially out in the middle of, for example, an oil field in remote parts of Texas or North Dakota—there is a risk of an electrical overload travelling. Often these remote sites do not have many trees in the vicinity, and oil field equipment will be frequently hit by lightning strikes. If the site is using copper, those lines will carry that electrical charge between products, and mobile systems and sensors that are connected could all blow out. By going wireless, users can eliminate that issue. There’s nothing for lightning to travel through.

Also, most of these systems are not transmitting gigabytes of data per second. Industrial data is made of small bits and pieces of data coming in from a number of devices, collecting at a central point, and then being transmitted back to a remote location. In total, these systems collect and use a tremendous amount of data but these devices themselves are not producing a lot.

MPT: How does the Digi XLR PRO compare with typical radios, such as those using frequency-hopping spread spectrum (FHSS)?

Aaron McNally: Many systems in the field today are frequency-hopping spread spectrum. In fact, Digi offers frequency-hopping models in the 900 megahertz range and on other wireless devices, but the XLR PRO uses chirp spread spectrum, which is a different frequency modulation than frequency-hopping. For frequency-hopping spread spectrum devices, as data is being transmitted across a range of frequencies, the device is detecting interference and literally “hops” that data transmission across these various channels to make sure nothing is lost by avoiding that interference and “noise.”

However, instead of hopping across frequencies, chirp spread spectrum “sweeps” its transmissions across frequency bands to send its data. It’s the XLR PRO’s Punch2™ Technology that leverages the chirp sequence to the whole spectrum of frequencies available in the unlicensed 900 MHz ISM band, broadcasting a signal that breaks through the noise, filtering and suppressing it away, and reliably delivers its data.

MPT: How does the XLR PRO’s Punch2™ Technology overcome noise-saturated RF environments?

Aaron McNally: Punch2™ is the magic that sits on top of this chirp spread spectrum technology. It improves receiver sensitivity and interference immunity, but it also improves multi-path recovery when a signal has physical obstacles in the way of transmission bouncing signals at different angles and sending them back.

The XLR PRO has a much better recovery potential than other types of systems. Users can also turn up or turn down the transmission from 9600 baud to 3 megabytes, and as they turn down from 3 megabytes they will improve their signal-to-noise ratio and interference immunities go up.

MPT: What can users in the oil and gas exploration/production industries expect from the XLR PRO?

Aaron McNally: The true story I give comes from an oil and gas company who set up a bunch of wells in an area with a series of frequency-hopping 900 megahertz radio systems, but not soon afterward a competing company set up one well with another 900 megahertz radio system nearby. Initially, the signal had some degradation but nothing too bad. But as their competitors added more wells, the environment became so noisy that both companies were having trouble sending and receiving signals.

That leaves only one practical solution: buying space in the privately licensed range from the FCC—along with the generally more expensive equipment that comes with it. However, the XLR PRO’s Punch2™ Technology filters out that noise in these frequency-saturated environments allowing for more consistent data transmission while maintaining high performance levels in the unlicensed 900 megahertz band.

MPT: How well is it suited for use in utilities?

Aaron McNally: With utilities, the problem is not just noise but distance. XLR is shorthand for “extra-long range,” and it is phenomenal technology. For example, I have worked with a family farm in southern Minnesota and their substation is in the middle of nowhere. Cellular coverage is often spotty at best and data may need to be transmitted to the next town or further for remote access to these systems.

Getting signal to these remote locations is key, and there is outstanding distance offered by the XLR PRO—upwards of 150 miles (241 kilometers) distance in between line of sight. Many of our engineers are based in Utah, where they conducted a mountaintop-to-mountaintop test achieving over 1 megabyte of throughput in excess of 100 miles. I’ve worked with wireless technology for twenty years and this is one of the best solutions I’ve ever seen. ■

MODERN PUMPING TODAY, March 2015

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!