In part one of this article, we offered a detailed look at the theory of operation for Coriolis flow meters, also known as mass flow meters, for applications requiring very precise delivery of high-value liquid product. In this concluding entry, we’ll examine the testing results as well as introduce some valuable observations from the field.

FLOW PRECISION

A test was designed to demonstrate and compare the accuracy of the Coriolis mass flow meter and the positive displacement meters historically used at Blackmer’s Research and Development Laboratory. To provide an alternate method of measuring flow, a 300-gallon (1135 liter) tank was placed on four 500-pound (226 kilogram) precision NIST-traceable load cells. The load cells and electronic instrumentation were selected so that the precision of the weight-flow measurement would have a tighter tolerance than the mass flow meter at some of the lower flow rates.

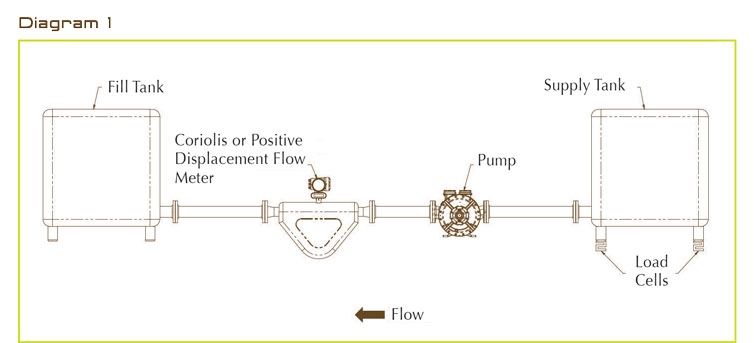

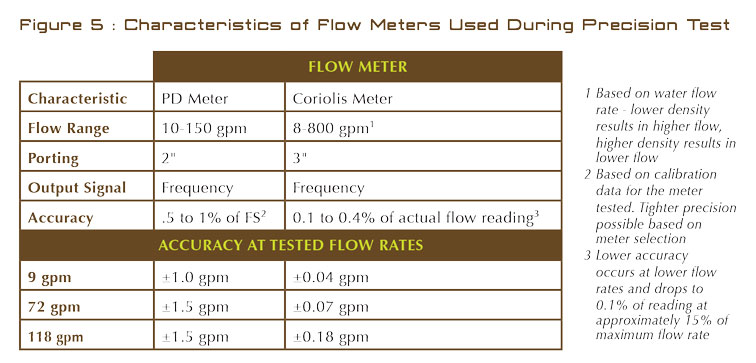

A pump and the test flow meter were piped to another tank such that all the flow moving from the supply tank was metered as it entered the fill tank. The test pump was operated at constant speed with minimum back pressure (no valve throttling) to obtain a constant flow rate while emptying the supply tank. The weight of the supply tank was recorded every 0.1 seconds so that a mass flow rate could be directly recorded. The density of the water was measured with an NIST-traceable hydrometer so the mass flow rate (measured in pounds per second) could be converted into a gallons-per-minute flow rate. A drawing of the test setup is depicted in Diagram 1, as well as a chart of the characteristics of the flow meters tested (see figure 5).

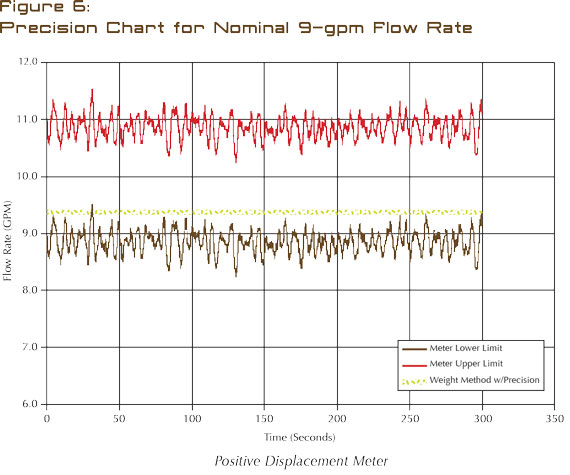

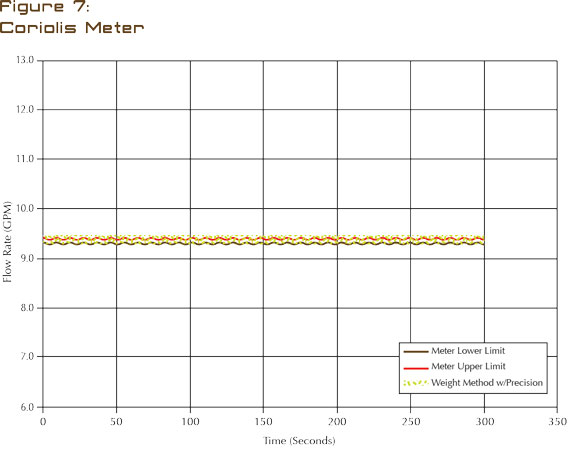

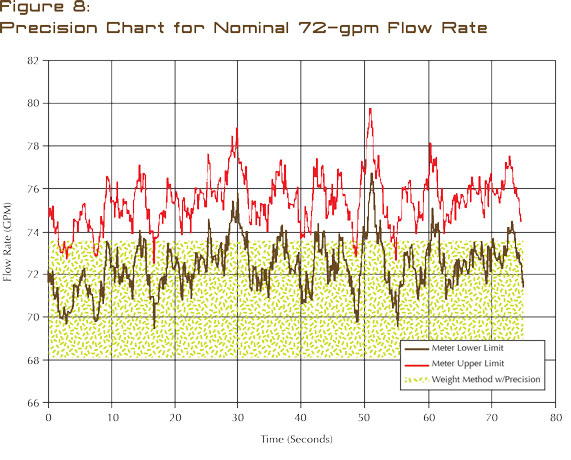

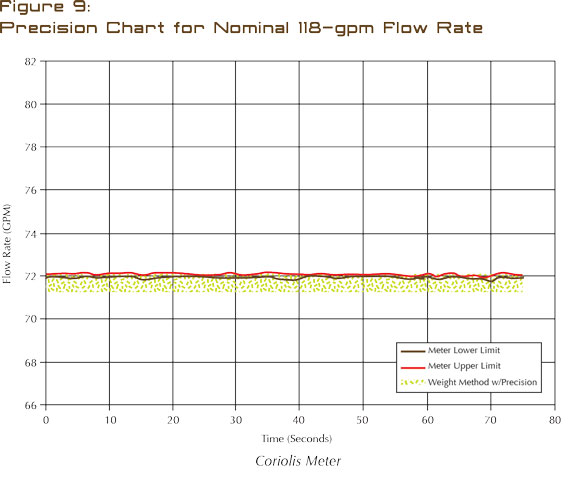

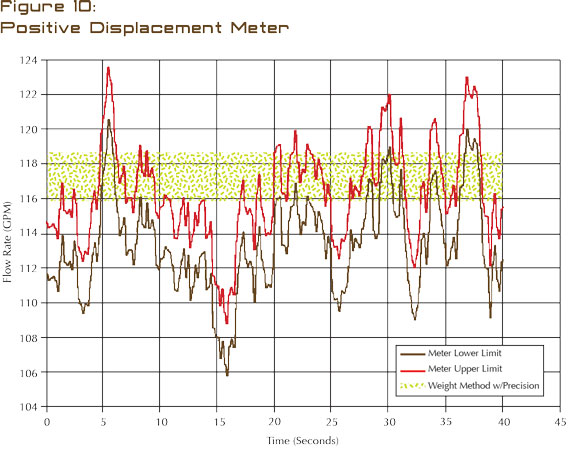

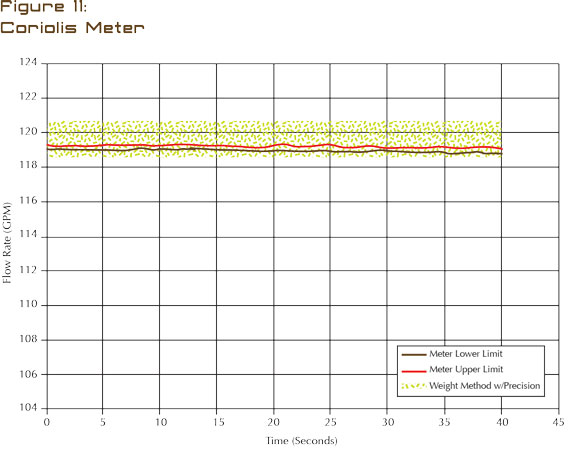

Three basic flow rates were tested: 9, 72, and 118 gallons per minute. Data was collected the entire time the pump was in operation, recording flow-meter readings and the weight of the supply tank. About five seconds after pump startup, flow became very consistent until the supply tank was nearly emptied. The data from the steady-state flow intervals is shown in figures 6 through 11.

The graphs show the precision of each test meter and the precision of the weight method of flow measurement. Precision of the flow meters is the published calibration/ accuracy specifications at the tested flow rates. The weight-method precision is a function of the accuracy of each load cell, the amount of weight that was moved during the measurement and the amount of time required to move the measured weight. The low flow rate (9 gallons per minute; or 34 liters per minute) produced the most precise weight-measured flow because more time was required to remove the approximately 900 pounds (408 kilograms) of water. As flow rate was increased, less time was required and the weight-method precision tolerances increased.

As can be seen, the precision of the Coriolis meter is much tighter than the positive displacement meter, and was as precise as the weight method at 9 gallons (34 liters) per minute and more precise at the higher flow rates. The Coriolis flow meter and the weight method have a high degree of correlation and statistically are indistinguishable over the entire time and range of flow measured. On the other hand, the positive displacement meter, with a much wider precision range, does not conform as well to the weight method of flow measurement.

An unanticipated error of the weight method did occur during the precision tests. It was observed that the weight measurements fluctuated much more than the precision of the load cells would indicate. The tank of water, sitting on four load cells, inadvertently became a spring-mass system. The weight on the load cells fluctuated with system vibrations, such as mechanical vibration and pressure pulses from the pump. To correct for this, the weight uncertainty was estimated by comparing the theoretical mass flow (overall weight change compared to overall time passed) to the actual observed weight loss for each recorded time interval. The average fluctuation for all of the time intervals was added to the overall precision of the weight method, increasing the tolerance of the flow rate. The interesting thing about this is that the positive displacement meter consistently produced more weight variation than the Coriolis flow meter.

As can be seen on the precision graphs, the tolerance of the weight-method flow rate is larger for the PD meter than the Coriolis flow meter, even though the flow rates are nearly identical. The widest discrepancy was observed at the mid-range flow rate. Earlier discussion of how pressure pulses may affect the Coriolis flow meter showed that this was not observed in the tests conducted. The system did not seem to affect the meter. The opposite of that was proven during the weight-method precision test; the meter has an effect on the system. While the effects of the Coriolis flow meter could not be separated from pump variations, the positive displacement meter effects are quantifiable.

OBSERVATIONS FROM THE FIELD

The decision to invest in Coriolis mass flow meter measurement technology in Blackmer’s Research and Development Laboratory and production facilities was based on observations from Blackmer’s customer base. Many Blackmer customers have evaluated Coriolis flow meters and found them to be the best flow-measurement solution in systems where Blackmer pumps are applied. Increased flow-measurement precision and higher reliability were the most common improvements cited by end-users. For example, EMCO Chemical Distributors, Inc. of Pleasant Prairie, Wisconsin, reports excellent results using Blackmer sliding vane pumps in systems that use Coriolis flow meters for flow measurement. A recent multiple pump installation at EMCO for railcar unloading has yielded highly reliable system performance and excellent measurement accuracy with no reported problems after eighteen months in operation.

Blackmer sliding vane pumps are often applied in fuel-transfer applications. Blackmer provides pumps to major petroleum distributors that have switched from positive displacement meters to Coriolis mass flow meters in systems where Blackmer pumps were installed. Again, information from the field is positive in the installed base where Blackmer sliding vanes pumps are used in conjunction with the Coriolis flow meters. This further supported Blackmer’s decision to investigate—and, ultimately, invest in—the technology.

DISCUSSION AND CONCLUSIONS

Flow meters from two highly respected equipment manufacturers were purchased in an effort to eliminate possible bias between “brands” of the same technology.

One unexpected observation that was discovered during testing was in noise generation. In both LPG and solvent tests, Coriolis mass flow meters (from both manufacturers) operated with less airborne noise than the positive displacement (PD) meters that Blackmer had been using. The PD meter devices generated their own pressure pulses in the discharge line. We had become accustomed to the noise and had accepted it. We were very favorably impressed with how quiet the new meters were in operation.

We attempted to operate the sliding vane pumps at speeds where the pressure-pulse frequencies would be at the same resonant frequencies as the Coriolis flow meters themselves. We then varied the speeds to levels (pressure-pulse frequencies) above and below the meter’s published natural frequency. We could not induce any constructive or destructive interference into the vibrating Coriolis tubes by intentionally operating them in the natural frequency range of the tube spring/mass system. Nothing we could do within the normal operation of the pumps caused any degradation of meter accuracy.

Proper mounting of the meter was found to be critical for accurate and reliable meter performance at low flow rates. Mounting the meter horizontally was the only application parameter that we determined to have an effect on the meters.

Measurement precision and repeatability were markedly better with the Coriolis flow meters than Blackmer’s PD flow-measurement technology. This was determined by measuring the weight (mass) of the liquid pumped with highly accurate NIST-traceable load cells to verify the actual performance of both the PD meter(s) and the Coriolis mass flow meters.

Blackmer’s customer base has a great deal of experience using Blackmer pumps with Coriolis mass flow-measurement technology. We have had no reports from the field of any incompatibilities or other issues to date after many years of service.

The meter test results from Blackmer’s Research and Development Laboratory have been compelling enough to convince us to install the Coriolis flow meters on our production test stands. We have installed an Endress+Hauser mass flow meter on one of our production pump test rigs. This rig tests three different sizes of Blackmer sliding vane LPG pumps daily. We have experienced greatly improved measurement accuracy and very good reliability in a production environment. ■

About The Author

Jeff Sietsema is the Research & Development Lab Manager, and Richard E. Foster is Director of Engineering for Blackmer®, the leading global brand of innovative and high-quality rotary vane and centrifugal pump, and reciprocating compressor technologies for the transfer of liquids and gasses. Part of PSG®, a Dover Company, Blackmer pumps and compressors are used in a multitude of applications in the Process, Energy, and Military and Marine markets. For more information, visit www.blackmer.com.

MODERN PUMPING TODAY, February 2015

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!