Part 2 of a 3-Part Series

In part 1 of this series, we looked at many of the ways in which pumps can be mounted—introducing some of the practical and financial considerations for best practices in base plate installation options. In this installment, we’ll examine more closely some of the “Best-in-Class” users’ decisions and an important exception to the general guidelines for secure-in-place installation.

EPOXY-FILLED OR FULLY-MOLDED EPOXY BASE PLATES

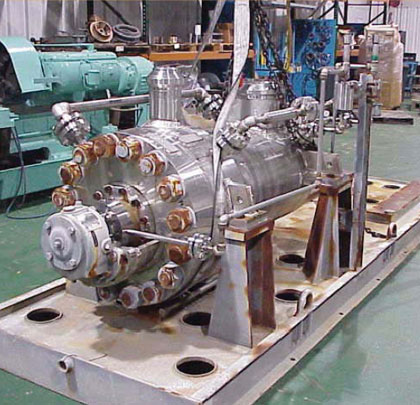

Best-in-Class users often specify and generally insist on full epoxy or epoxy pre-filled steel base plates. Both full epoxy and epoxy pre-filled base plates dispense with the labor-intensive conventional grouting procedures that will be needed with old-style hollow base plates. Much labor and corrective maintenance can be eliminated by buying either solid epoxy or steel base plates pre-filled with epoxy. The latter can also be fabricated in-plant. The conventional hollow base plate in figure 4 is being prepared for filling with epoxy. Once filled, this base plate becomes a monolithic block that will never twist and never get out of alignment (see reference 4). The overall cost of this superior mounting is usually below that of conventional leveling and grouting methods. In other words, the life cycle costs of full epoxy or epoxy pre-filled steel base plates can be overwhelmingly attractive (see reference 3).

Since about 2000, Best Practices Companies (BPCs) have increasingly used “monolithic” (all-in-one, and/or epoxy pre-filled steel) base plates in sizes approaching about 5 feet by 8 feet (1.5 meters by 2.5 meters). Larger sizes become cumbersome due to heavy weight.

In the size range up to about 5 feet by 8 feet (1.5 meters by 2.5 meters), conventional grouting procedures are being phased out in favor of base plates pre-filled with an epoxy resin or grout (see reference 3). The epoxy filling process includes five successive stages, all done under controlled conditions. The entire process is most often done before shipment to the site; at other times a competent work team is entrusted with items 3 through 5 at the destination or owner’s plant site:

- Base plate fabrication. (No pour holes are needed for pre-filled base plates, although figure 4 shows these large openings)

- Stress relieving

- Pre-grouting (grit blasting followed by primer application) in preparation for pre-filling. (If there are large pour holes, the inverted base plate must be placed on a sheet of plywood, figure 4)

- Fill with epoxy grout and allow it to bond and cure

- Invert and machine the mounting pads to be flat; then verify flatness before

shipment. Protect and ship—possibly even with pump, coupling and driver mounted and final-aligned.

The advantage of pre-filling is notable. Jobs with pumps in the 750 kilowatts category and total assemblies weighing over 24,600 pounds (~11,000 kilograms) have been done without difficulty on many occasions. In contrast, a conventionally grouted base plate requires at least two pours, plus locating and repair-filling of voids after the grout has cured. Epoxy pre-filled base plates travel better and arrive at the site flat and aligned, just as they left the factory. Their structural integrity is better because they do not require grout holes. Their installed cost is less and their long-term reliability is greatly improved.

SECURING PUMPS IN PLACE—WITH ONE EXCEPTION

Again, and for general emphasis: Proper field installation of pumps has a measurable positive impact on pump life. Even a superb design will give poor results if poorly installed. A moderately good pump design, properly installed, will give good results (see reference 2). Proper installation refers to a good foundation design, no pipe strain and good shaft alignment, to name just a few. No pump manufacturer designs its pumps strong enough to act as a solid anchoring point for incorrectly supported piping, or piping that causes casings and pump nozzles to yield and deflect. Also, pumps have to be properly secured to their respective base plates and these base plates have to be well-bonded to the underlying foundation. Epoxy grout is used to do this bonding in modern installations.

There is one exception, however: Vertical in-line pumps (figure 5) are not to be bolted to the foundation. They are intended to respond to thermal and other growths of the connected piping and must be allowed to float or slide a fraction of an inch in the x and y-directions. The foundation mass under vertical in-line pumps can be much less than that under the more typical horizontal pump. For vertical in-line pumps it is acceptable to make the concrete foundation about one-and-a-half to twice the mass of the pump-and-driver combination (see reference 3). A decade-long rule of thumb for horizontal pumps aims for a foundation mass of 3 to 5 times the combined mass of pump, driver and base plate.

A LOOK AHEAD

In the conclusion of this series, we will look at what pump users need to know about with regard to the best-practice specifications for alignment jacking provisions and create an adaptable checklist for base plate installation options and guidelines. No installation checklist can cover the entirety of pump users’ experiences and specifications, but some concerns remain worthy of attention in the majority of applications. ■

REFERENCES

Bloch, H. P., and A. R Budris. Pump User’s Handbook: Life Extension, 4th Edition (2013). Fairmont Press (ISBN 0-88173-720-8).

Bloch, H. P., and F. K. Geitner. Major Process Equipment Maintenance and Repair,” 2nd Edition. Gulf Publishing Company (ISBN 0-88415-663-X).

Bloch, H. P. Pump Wisdom: Problem Solving for Operators and Specialists

(2011). John Wiley & Sons (ISBN 978-1-118-04123-9).

Monroe, Todd R. and Kermit L. Palmer. “Methods for the Design and Installation of Epoxy Pre-filled Base Plates” (1997 Marketing Bulletin). Stay-Tru® Services, Inc., Houston, Texas.

Barringer, Paul, and Todd Monroe. “How to Justify Machinery Improvements Using Reliability Engineering Principles,” Proceedings of the Sixteenth International Pump Users Symposium (1999). Turbomachinery Laboratory, Texas A&M University, College Station, Texas.

■ ■ ■

[divider]

ABOUT THE AUTHOR

Heinz P. Bloch, P.E., is one of the world’s most recognized experts in machine reliability and has served as a founding member of the board of the Texas A&M University’s International Pump Users’ Symposium. He is a Life Fellow of the ASME, in addition to having maintained his registration as a Professional Engineer in both New Jersey and Texas for several straight decades. As a consultant, Mr. Bloch is world-renowned and value-adding. He can be contacted at heinzpbloch@gmail.com.

MODERN PUMPING TODAY, June 2014

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!