In 1978, an innovation occurred in centrifuge technology that changed the market. The dominant centrifuge technologies of the time, the nozzle disk centrifuge and continuous batch, imperforate basket centrifuge were replaced by a re-invented continuous decanter centrifuge using a hydraulic assist. This feature significantly increased throughput while improving performance at reduced O&M costs to the end user.

Thirty years later, another significant breakthrough has occurred. A new generation sludge thickening technology, the THK, is the Centrisys re-interpretation of the synergistic hybridization of the “hydraulic assist” and “Type B” continuous decanter centrifuge. This is historically predicated upon the following considerations.

First, the Type B design demonstrated superior no polymer performance versus the hydraulic assist method (compare figure 1B to figure 2 in our article “History Repeats Itself,” Modern Pumping Today, Feb. 2013: 33-34). There is more cylinder for clarification purposes (sigma is proportional to the clarification length). In particular, the nozzle approach was more effective in larger centrifuges due to practical constraints on the size of the nozzle needed for smaller designs. Hydraulic assist technology ended with unresolved scale-up issues in the commercial transition from Polymizer to the more expensive Maximizer designs.

A PROBLEM OF SCALE

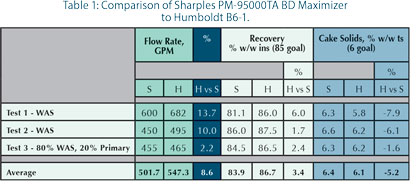

Table 1 is a comparison of the largest size hydraulic assist design competitively evaluated against the largest size Type B design. Three tests took place over 1000 hours targeting 6 percent cake solids and 85 percent recovery levels. Testing was conducted at 2050 G-level versus 802 G-level operations, respectively.

As seen in table 1, the Maximizer design boasted enhanced Sigma capabilities versus the Type B Humboldt design. However, this measure of clarification capability did not translate to additional throughput but instead only resulted in higher power consumption—that is, 0.38 horsepower/gpm on the Maximizer versus 0.31 horsepower/gpm on the Type B (approximately 18 percent less on Type B at 500 gallons per minute).

The hydraulic assist design was more reliable from the O&M standpoint. The gamble was taken in increasing the bowl angle for the Type B design improved capacity but often resulted in the back-up of trash and grit causing excessive wear and/or downtime. In short, the Type B design often operated without the functional ability to convey large amorphous trash and grit from the design resulting in either plugging of nozzles or the milling of trash and grit to a level that could be discharged through the small nozzles (resulting in excessive wear). In the above comparison and despite superior process performance, Type B was disqualified when the nozzles plugged once (after over 1000 hours operation).

THE BEST OF BOTH WORLDS

Specifically, the Centrisys THK uses proprietary technology that re-engineers both designs to enhance the strengths of each precursor while eliminating the weaknesses demonstrated at that time. These changes are schematically represented in figure 1. First, capacity per unit size is further increased by eliminating the cone section of the centrifuge via proprietary technology (patent pending), which efficiently conveys grit and trash radial and inward.

Also, elimination of the cone section negates the commercially rationalized steeper beach designs that compromise process stability in favor of additional cylinder length and/or pool depth. Nearly the full cylinder is used for clarification. In addition, deeper pool depths are now possible which also add to capacity and can be estimated as being proportional to the additional G-volume for clarification.

Furthermore, the THK offers precise control of cake discharge solids (patent pending) by means of hydro-pneumatic flow control of the thickened WAS. In short, higher cake solids can be efficiently traded for additional capacity based on the operating lines characteristic of thickening centrifuges.

APPLIED INNOVATION

Finally, design innovation is applied to push the envelope of technology. These factors are summarized as follows:

- Current thickening designs have not resolved the issues of earlier designs such as why additional Sigma did not provide the capacity boost predicted for the Maximizer design.

- The effects of “Hydro-Pneumatic” control versus hydraulic assist of soft cake solids discharge is analogous to comparing “rear wheel drive to four-wheel drive” on slippery slopes. Higher rates can be maintained because better control can be easily automated.

- Commensurate with significantly increase throughput for the same bowl Outer Diameter (OD) and length/ diameter (L/D )ratio, the Centrisys THK uses proprietary technology to reduce the Total Brake horsepower/gpm by 50 percent compared to earlier designs.

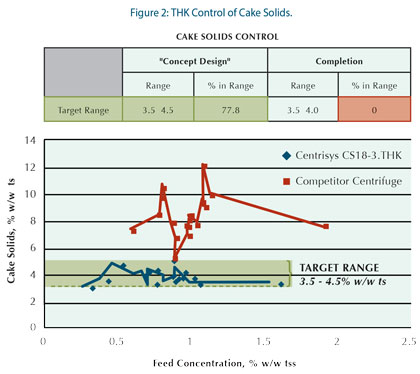

Less obvious but documented herein is that the Centrisys THK design has much better control over maintaining the cake consistency than either the Humboldt Type B or the Maximizer design. The hydraulic assist approach had difficulty on larger centrifuges maintaining thickened cake consistencies between 4 to 6 percent. Instead, recent comparative data (table 2) demonstrated the clear advantage of the Centrisys THK design for maintaining targeted cake solids versus the current version of a Maximizer design (XM-706).

The cake solids range targeted in the test was 3.5 to 4.0 percent wastewater with plant personnel operating the equipment and conducting the data analysis. The Type B centrifuge did have better control of cake solids versus the hydraulic assist approach but would not have performed much better for the same comparison because the flow rate to both centrifuges was kept relatively constant.

The ability to maintain consistent cake solids on the Type B design was based upon keeping the volume of solids through the nozzles constant. Therefore, the flow rate needed to increase/decrease proportionally to the feed concentration. In the example from table 2, feed concentrations ranging from 0.33 to 1.62 would require over a 5:1 ramp up / turn down capability of the equipment. Type B would have fluctuated significantly under those scenarios. Instead, the Centrisys THK design uses hydro-pneumatics to control (patent pending) the level of cake solids in a much more narrow range (figure 2) than possible before.

Air is injected through the axial center of a Viscotherm Rotodiff via a rotary air transfer seal integrated into the design and then functionally distributed into the thickened cake solids which promotes grit and trash transport while controlling the cake discharge rate via volume displacement.

In summary, the relationship between the liquid and solids discharge is set to allow for the benefits of hydraulic assist through an adjustable nozzle on the headwall. In this mode, the Centrisys THK centrifuge can maintain cake solids relatively independent of flow rate. The pneumatic injection of air is then applied to give precise control over the desired level of cake solids. As such, control over the discharged cake solids can be maintained over a widely fluctuating feed flow rate and solids concentrations.

NEWFOUND RELIABILITY

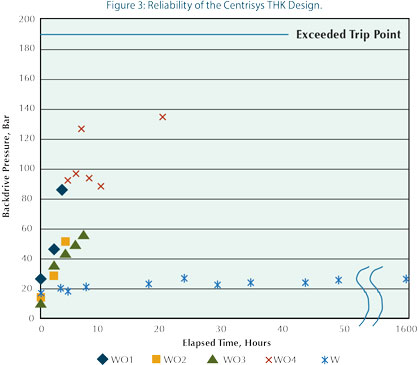

The ability to operate without a conical section of the bowl is not new. However, to be able to do so reliably with grit and trash in the system is unique. The Centrisys THK development not only overcame the problem of a torque build-up on the Type B design (see figure 3), but demonstrated better performance reliability than the hydraulic assist method. Specifically, the THK design was operated continuously over a two month period alongside a Maximizer design.

As discussed earlier, the hydraulic assist approach has proven extremely reliable across the country. However, the plant tested at has “sugar sand” in the process which was seen to randomly slug the centrifuges with up to 6 percent concentrations of grit laden WAS. Under these conditions, the XM 706 plugged up with solids and was down for weeks while the Centrisys THK technology kept the plant operational. In summary, the THK demonstrated improved reliability versus the commercial benchmark.

CONCLUSIONS

Three decades ago, the design innovations of the hydraulic assist method redefined what plant operators could expect in centrifuge technology. The Centrisys THK design is poised to duplicate that feat again. At significantly higher flow rates (per square foot of floor space) in a more cost-effective design, turn-key installation costs are reduced by 40 to 60 percent versus current centrifuge technology. Operating costs are reduced by a better control of cake solids, by increasing “no polymer” commercial capacities and by reducing power consumption (up to 50 percent at 0.08 to 0.2 horsepower/gpm estimated range). Maintenance costs are reduced by minimizing unnecessary downtime and the time between re-builds on the equipment. Both cause and effect are factored into the serviceability of the equipment by making most wear parts replaceable in the field.

_________________________________________________________________________

ABOUT THE AUTHOR

Michael Kopper is the president and Robert G. Havrin is the director of technology for Centrisys Corporation, an award-winning, certified, a global provider of separation equipment, parts, repair, and service. Learn more by visiting www.centrisys.us.

_________________________________________________________________________

MODERN PUMPING TODAY, March 2013

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!

![]()