WAGO CORPORATION

750-538 Module

Via internal system voltage, WAGO Corporation’s new 2-Channel Relay Output Module directly activates Intrinsically Safe circuits, powering actuators in hazardous locations. Unlike traditional solid-state hazardous location relays, the unique 750-538 carries two changeover contacts for activating Zone 0/20 and 1/21 devices, for example, relays, solenoid valves, contactors or optical/acoustic signal generators. This supports diverse hazardous location applications in oil and gas processing, wastewater treatment, brewing/distillation, and more. The electro-mechanical 750-538’s switching voltage/current is rated 125 VAC/0.5 A and 30 VDC/1 A; the maximum permissible limits depend on the actuator’s location per EN 60079-11. 750-538’s Normal Open (NO) contacts are electrically isolated; on-board LEDs indicate relay switching status. 750-538 joins WAGO’s growing EX i portfolio of nearly 20 Intrinsically Safe Modules and power supplies. Highly modular digital, analog and specialty modules are available 1-, 2-, 4- or 8-channels—users only purchase the I/O needed. All EX i devices are compatible with WAGO-I/O-SYSTEM buscouplers, PLCs and IPCs. For additional information, visit www.wago.us, call 800.DIN.RAIL, or email info.us@wago.com.

ROTORK VALVEKITS

LNG Mounting Kits and Spool Pieces

In one of Valvekits’ latest international contracts, the company is supplying over 250 valve mounting kits and spool pieces for a liquefied natural gas (LNG) facility under construction in America. Designed and manufactured at the Valvekits UK factory, the mounting kits and spool pieces will provide adaptation for fluid power actuators on ball valves ranging in size from 3 to 42 inches (75 to 1000 millimeters), including a number of cryogenic valves. The Valvekits products are being supplied in batches to Rotork’s group facilities in Bilbao, to meet the production schedule of the Spanish valvemaker Poyam Valves, located at nearby Idiazabal. The final destination is a new LNG production plant being built by Bechtel International Inc. for Cheniere Energy Inc. on the Sabine River in Cameron Parish, Louisiana. All Valvekits mounting kits are manufactured in accordance with their BSI ISO9001:2008 certification. Designs are produced in-house using the latest Solid Edge software and manufactured with machinery that is the focus of a continuous investment plan to keep the company at the forefront of technology. For more information, email sales@rotorkvalvekits.com or visit www.valvekits.co.uk.

HAYWARD FLOW CONTROL

Pleated Filter Cartridges

Hayward Flow Control announces the expansion of its pleated filter cartridges to complement our industry leading CFLV Series filters. Manufactured in either polypropylene or cellulose media, the new high efficiency cartridges provide high surface filtration and comprehensive service life. the cartridges are designed for use with Hayward’s CFLV and MFLV cartridge adapter kits. The Hayward pleated filter cartridges offer the right product choice for multiple liquid purification requirements. The high-tech pleated media provides excellent particulate removal as well as low pressure drops. The greater surface area ensures longer service life than most filter bags due to higher flow and particulate holding capacity. All cartridges feature DOE Plastisol PVC End-Caps for maximum sealing capability. Typical applications or installations include but not limited to waste and water treatment, chemical processing, aquatic and animal life support systems, manufacturing processes, marine and off-shore filtration applications and systems. For more information, contact Dave Stewart at 336.712.9900.

VAL-MATIC

SuperValve

Val-Matic® Valve and Manufacturing Corporation’s air valve SuperValve line offers premium water and wastewater air valves featuring type 316 stainless trim and bolts, internally and externally fusion-bonded epoxy coating, holiday testing, and clean water valves with EPDM seats and orifice buttons. Val-Matic’s Air Valve SuperValves are certified lead-free in accordance with NSF/ANSI 372 along with the clean water SuperValves certified to NSF/ANSI 61 for drinking water system components. Contact Val-Matic to get your premium SuperValve today. For more information regarding the Val-Matic air valve SuperValve line, visit www.valmatic.com.

ABBA PARTS

Bladeless Single Channel Impeller

ABBA’s “bladeless” single channel impeller will dramatically reduce or virtually eliminate clogging problems associated with unscreened raw sewage. The single channel or “bladeless” impeller that typically replaces a standard 2 vane impeller is best suited for smaller pumps, 3 inches up to 5 inches discharge, and is an ideal solution for pump stations with low sewage flows as well as unmanned pump stations. ABBA’s “bladeless” single channel impeller will handle 10 to 25 times more solids compared to a standard 2 vane impeller and is designed to efficiently handle stringy, fibrous trash. Benefits include reduced clogging problems, higher efficiency at low flows, less maintenance time required, and improved reliability. Also, retrofits are available for many pump makes and models and it is cost effective when compared to other solutions for clogging. To learn more, visit www.abbaparts.com, email wendy_j@abbaparts.com, or call 800.268.5142.

ASHCROFT INC.

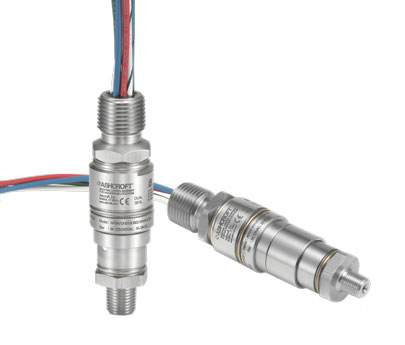

A-Series Miniature Pressure Switch

Ashcroft introduces a new compact stainless steel explosion-proof pressure switch. The new A-Series miniature pressure switch is now available in a SIL capable explosion- proof configuration for hazardous areas. With 316 stainless steel construction, an IP67 rated enclosure and an operating temperature range from -40 to 192 degrees Fahrenheit (-40 to 89 degrees Celsius), the rugged dual-seal rated A-Series explosion-proof pressure switch stands up to the most extreme environmental conditions. Agency approvals and certifications include FM, UL, ATEX, IECEx, CSA, CRN, CE, RoHS, as well as SIL 3 capability. Pressure ranges from vacuum through 7500 psi are offered along with a broad selection of pressure inlet fittings. Learn more about Ashcroft® A-Series pressure switches by visiting www.ashcroft.com or calling the Ashcroft ActionLine® at 800.328.8258.

RFG PETRO SYSTEMS

RFG Box-Guide

RFG Petro Systems, a designer and manufacturer of specialty tools and equipment for oil and gas well production, today announced the introduction of the RFG Box-Guide™, a guided coupling for down-well sucker rods that incorporates Martin Polymer™, a new advanced material which provides industry-best wearability in this demanding application, and a unique guide design that helps keep the rod string centered in the tube while eliminating steel-to-steel contact between the coupling and tubing wall. The RFG Box-Guide coupling is precision-machined from 8630 USA steel and over-molded with the proprietary Martin Polymer in an exclusive manufacturing process, using an array of highly specialized equipment, according to Steve Ostermann, president, RFG Petro Systems. He notes that the design incorporates durable and robust fins that serve to help keep the rod string centered, adding that this unique product and its specialized manufacturing process are patent-pending. For more information about RFG Petro Systems products or becoming a distributor, visit www.rfgpetrosystems.com.

ARMSTRONG FLUID TECHNOLOGY

Compass Circulator

Armstrong Fluid Technology has introduced a new circulator featuring industry-leading Design Envelope technology. The new Compass circulator helps contractors and wholesalers with easy selection, fast installation and extremely broad performance capabilities for application to a wide variety of installations. The new Compass circulator also helps homeowners reduce energy consumption and operating costs. In “auto” mode, (one of eight operating modes available for selection) the Compass circulator adjusts operating speed to match HVAC demand at any given moment. Over time, the Compass circulator also learns a system’s patterns of demand and appropriately adjusts output to reduce energy usage even more. For more information on the innovative new Compass circulator and to see a video on its energy savings benefits, visit www.armstrongpumps.com/compass/literature.asp and www.armstrongpumps.com/compass/index.asp.

JET EDGE, INC

iP60-50 Waterjet Intensifier Pump

Jet Edge’s iP60-50 waterjet intensifier pump is a 50-horsepower water jet intensifier pump rated at 60,000 psi (4,100 bar). It is capable of producing output pressures from ,000 to 55,000 psi (3800 bar) with flow rates of 0 to 1 gallons (3.8 liters) per minute to a variety of abrasive waterjet and waterjet cutting systems and UHP surface preparation equipment. Jet Edge offers a wide range of precision water jet cutting systems, mobile waterjet cutters and surface preparation tools, including precision waterjet cutting machines, portable waterjet cutting systems, ultra-high pressure intensifier pumps, waterjetting tools and waterjet parts and accessories. Jet Edge has the widest range of waterjet pumps on the market, from 25-280hp, including 36KSI (2500 bar), 60KSI (4100 bar) and 90KSI (6200 bar) models. Electric and diesel pumps are available. Jet Edge also offers custom engineering and OEM integration support. For more information, visit www.jetedge.com or call 763.497.8700.

_________________________________________________________________________

MODERN PUMPING TODAY, August 2013

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!

![]()