Solids handling and sludge dewatering are key processes in a wastewater treatment plant. In addition, water treatment dewatering and sludge handling are also required due to sludge from sedimentation processes. In all of the handling operations pumping is typically required to move the sludge from one process to another. The thickness of the sludge will determine if a centrifugal or positive displacement pump is required. Most primary and secondary sludge can be pumped with a centrifugal pump. Thickened or dewatered sludge may require a positive displacement pump. The pumps used for solids handling will require pump optimization and efficiency as needed for all pumping applications.

Energy efficiency and greenhouse gas reduction are going to continue to be a concern for all water and wastewater treatment plants. Operational cost reduction is required to offset rising energy prices, increased operational demand and reduction in infrastructure funding. In addition, to achieve a net-zero energy plant, water and wastewater treatment plants will require all process to become more energy or operationally efficient.

A CLOSER LOOK

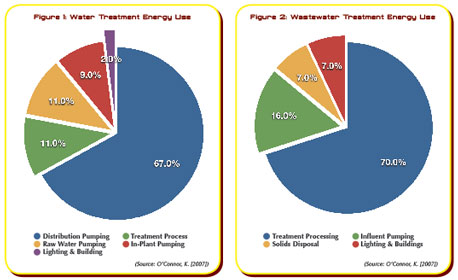

Let’s take a more in depth look at the solids handling and sludge dewatering processes in the water and wastewater Industry. These facilities must treat and move massive amounts of water for influent and distribution flow or risk various public health issues. Further, the solids that leave the plants must be treated and integrated or disposed of properly in the environment. A review of energy usage for water and wastewater treatment plants reveal that solid handling and dewatering are a small amount of the overall energy usage of a plant. See figures 1 and 2.

However, the operational costs can make a significant contribution in providing energy for the plant and reducing landfill and transportation costs. In addition, sludge reuse can be a benefit to other products that can be sold to the public.

SLUDGE PROCESSING

The first step in sludge processing is mixing the primary and secondary sludge and then thickening it before transferring to digestion. A typical process of thickening is a sedimentation process and uses a clarifier. NEMA Premium® efficiency motors can be installed on the thickener to gain energy efficiency. Sludge transfer pumps move the thickened sludge to the digester. The pumps for the thickened sludge may be positive displacement type; however, with specific gravity of the sludge at 1.3 to 1.05, centrifugal pumps could be used. The PD pumps are a better application because of possible grit in the sludge. VFDs and NEMA Premium® efficiency motors used on positive displacement pumps will enhance energy efficiency.

AEROBIC DIGESTION

Aerobic digestion is the biological oxidation of sludge under aerobic conditions. The volatile solids loading and percent solids destruction are about the same as in anaerobic digestion (Reynolds and Richards 1996). A thickener could also be supplied after the aerobic digestion with recycle pumps and is similar to the operation of a secondary clarifier. The recycle pumps will require positive displacement pumps.

Energy requirements will be higher than anaerobic digestion; however, operation of the system will be simpler. VFDs and NEMA Premium® efficiency motors will give some energy efficiency benefits. Additionally, as in activated sludge, aeration needs to be controlled with a dynamic control system with feedback from DO sensors to VFDs for the blowers. Note that GHG production will also be greater than anaerobic digestion.

ANAEROBIC DIGESTION

Anaerobic digestion degrades organic sludge by biological oxidation by microorganisms under anaerobic conditions. Further, it is the most common type of sludge treatment (Reynolds and Richards 1996). A thickener could also be supplied after the anaerobic digester before processing the sludge to dewatering. Further, a recycle pump could be provided to mix digested sludge with fresh sludge. The recycle pump will require positive displacement pumps. Mixing will be required for anaerobic digestion and is accomplished with mechanical mixers or gas recycle with compressors. Anaerobic digesters will also require sludge temperatures of 86 to 89 degrees Fahrenheit (30 to 32 degrees Celsius). The digester gas produced is used for heating the sludge. VFDs and NEMA Premium® efficiency motors will give energy efficiency benefits for recycle pumps and mechanical mixers. Figure 4 is a picture of anaerobic digesters.

Anaerobic digesters are more efficient than aerobic digesters. Additionally, the methane gas produced in a digester can be used for energy production. WEF reports 195 kilowatts of electricity can be produced per 10 dry tons (9.07 tonnes) of sludge processed (Water Environment Federation 1997). The digester gas can be used to drive engine generators or micro turbines; or; engines for pumps and blowers. The heat off of the engines can be used to heat the anaerobic sludge. Additionally, providing a dynamic control system with monitoring and feedback capability for sludge recycling and mixing will assist with energy efficiency.

In the second part of this feature, we’ll examine the sludge handling and dewatering implications of belt filter presses and other filtering processes, with careful attention paid to their effect on energy consumption. ■

REFERENCES

O’Connor, K. (2007). “Improving Energy Efficiency of Your Municipal Treatment Facility.”

Reynolds, T. D., and Richards, P. A. (1996). Unit Operations and Processes in Environmental Engineering, Second Ed., PWS Publishing Compan. Boston, MA.

Water Environment Federation. (1997). Energy Conservation in Wastewater Treatment Facilities, Manual of Practice no. MFD-2, Water Environment Federation.

_________________________________________________________________________

ABOUT THE AUTHOR

Lee E. Ferrell, P.E., BCEE, CEM, is a water and wastewater energy and process consultant for Schneider Electric’s Water Wastewater Competency Center. He has more than twenty-five years of industry experience and serves as the chairman for the AWWA Energy Management Committee.

_________________________________________________________________________

MODERN PUMPING TODAY, May 2013

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!

![]()