By Benson Hougland, Opto 22

In last month’s installment of this article, we introduced how the new groov RIO® family from automation manufacturer Opto 22 offers a simple solution in an increasingly complex era of connectivity and technical capabilities. In this concluding segment, we’ll focus on some of the details that best illustrate the product’s use in the real world.

EDGE I/O IN ACTION

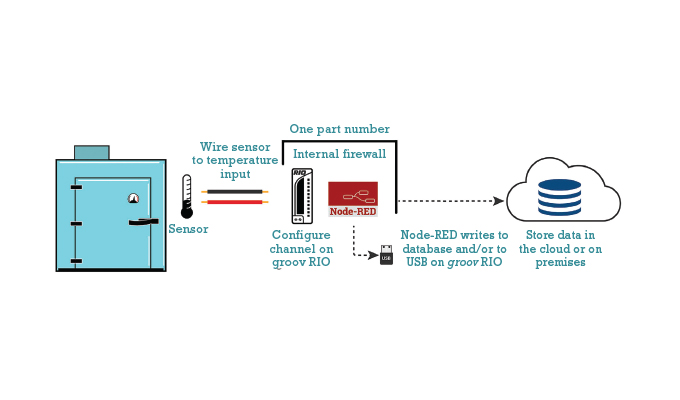

First, specifying I/O for a particular application becomes much simpler. Because groov RIO supports thousands of unique I/O configurations from a single device, you no longer need to identify and procure specific I/O modules. You can order just one part number. Second, mounting the unit and connecting it to a standard Ethernet network are easier.

You place groov RIO near the sensors or equipment with the signals you want. RIO’s operating temperature is -4 to 158 degrees Fahrenheit (-20 to 70 degrees Celsius), it is UL Hazardous Locations approved and ATEX compliant, and it can be panel or DIN-rail mounted. An enclosure may not be required, especially in low-voltage applications.

groov RIO attaches to an Ethernet network through one of its two switched Gigabit interfaces. You can use power over Ethernet (PoE) with a PoE switch, or provide 10-32 VDC power. The device automatically receives an IP address from your corporate LAN’s DHCP server, just like most other smart devices on an Ethernet network. Note that wireless LAN networking is also supported through optional USB WiFi dongles.

Once the unit is in place, you open a web browser and create a secure user account, configure I/O channels, and set up data communications for your application. The following sections list the steps to complete three of our simple applications.

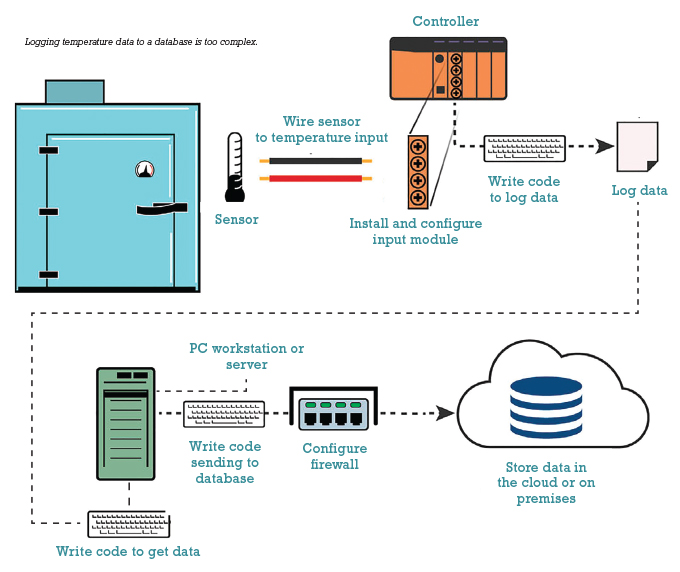

LOG REFRIGERATION UNIT TEMPERATURE TO A DATABASE

- Wire one of the first eight channels to a low-cost, simple two-wire ICTD (integrated circuit temperature device) temperature sensor and place the sensor in the refrigeration unit.

- From a computer or mobile device, securely log into groov RIO and use the browser-based groov Manage software to configure the channel as an ICTD input sensor.

- Still in your web browser, open the embedded Node-RED editor. Use pre-built nodes to create a simple flow that moves the temperature data to an on-premises or cloud-based database, like MariaDB, Microsoft SQL Server, or PostgreSQL.

You could also write a flow to log the temperature to local on-board, power-fail-safe flash memory, or to an installed USB memory stick connected directly to groov RIO’s USB port—especially handy if the remote location has no internet connection.

SEND COMPRESSOR ON-TIME TO A CLOUD ANALYTICS SYSTEM

- Wire one of the first two I/O channels to the compressor’s run/stop contact. In a web browser, configure the channel as a discrete input with the on-time totalizing feature. groov RIO automatically totals the amount of time the compressor is running.

- Open Node-RED and create a simple flow to move totalized data to the analytics system.

PUBLISH DATA TO A SCADA SYSTEM

- Wire process instrumentation transmitters (like level, flow, or pressure) to the first four I/O channels and configure as analog inputs (voltage or current).

- In groov Manage, configure MQTT communications to publish channel data to an MQTT broker. SCADA systems can then subscribe to data from the broker.

If you have Ignition from Inductive Automation®, you can use the Cirrus Link MQTT Distributor module to publish directly to Ignition, and use the MQTT Engine module to subscribe to MQTT Sparkplug-B payloads, which Ignition understands.

An efficient publish-subscribe method of communication like MQTT reduces security concerns by eliminating open network ports, and provides a high-performance, two-way communications path for both monitoring and control.

WHAT’S YOUR PROJECT?

These three examples point out some key ways in which an edge I/O product can simplify your IIoT projects. Do you have a simple idea you’d like to realize without the complexity and cost of a typical IIoT project? Take a look at newer I/O products like groov RIO and see if they’ll do the job for you.

FOR MORE INFORMATION

Opto 22 was started in 1974 by a co-inventor of the solid-state relay

(SSR), who discovered a way to make SSRs more reliable. Opto 22 has consistently built products on open standards rather than on proprietary technologies. The company’s latest product line, groov RIO®, provides compact, autonomous remote I/O

that is ideal for communicating field data in IIoT applications. All Opto 22 products are manufactured and supported in the USA. Most solid-state SSRs and I/O modules are guaranteed for life. The company is especially trusted for its continuing policy of providing free product support and free pre-sales engineering assistance. For more information, visit www.opto22.com.

MODERN PUMPING TODAY, July 2020

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!