By Mark Magda, Mueller Water Products

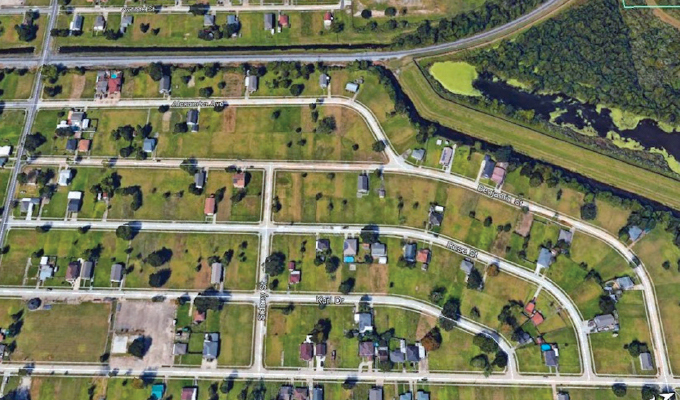

St. Bernard Parish is situated southeast of New Orleans in the state of Louisiana. In 2005, hurricane Katrina caused great devastation to the area and cut its population from 67,000 to 45,000. With spotty redevelopment and more water capacity than is needed for today’s residents, the Parish has been paying close attention to maintaining its water quality.

The Department of Health and Hospitals (DHH) notified the water department that there had been two deaths related to Naegleria Fowleri, colloquially known as the “brain-eating amoeba” in St. Bernard Parish. This free-living bacteria-eating amoeba is found in warm unchlorinated freshwater such as ponds, lakes, rivers and hot springs. If contracted by humans, this pathogen can cause a deadly infection in the brain.

Jacob Groby, superintendent of quality control for the parish, worked together with the DHH to collect water samples from over 100 points in the distribution network. The Parish has always been vigilant in monitoring water quality, but working together with DHH, they determined that their sampling protocols were no longer adequate as some areas reported lower than acceptable levels of CL2 and higher levels of Nh3 which can be conducive to bio-film growth.

TESTING BEGINS

Testing for Naegleria Fowleri requires analysis in specialized labs such as the Center for Disease Control (CDC) and Biological Consultants Services. In addition, monitoring of other factors that exert pressure on water quality need to be checked and addressed. For example, the parish does additional testing in low residential population sections of the distribution system for total chlorine, mono-chlorine, free ammonia, nitrite, pH, dissolved oxygen, and temperature using a portable Hach SL-1000 Portable Parallel Analyzer. Nitrate levels are monitored with a HACH Colorimeter II Filter Photometer. Both units are portable and easy to use, providing quick in-the-field analysis. Additionally, each sample is tested for adenosine triphosphate (ATP) levels. By tracking trends, not just daily results, water operators are able to change water conditions before they become a problem.

Groby explains, “Because our problem is unique to a surface water system, we had no prior cases to fall back on for experience. We had to rethink the age and time of water in our system, so the only logical way to do that is to cause the water to move through the system, identifying the point before we lose the chlorine residual which causes an increase in nitrification levels which is favorable for bacteria.”

To move water through the distribution system, the Parish installed 50 Hydro-Guard TAPS flushing stations with a custom 2-inch Singer valve that optimizes the flushing process for their pipe size providing the correct velocity to pull fresh water into each zone. This, coupled with the pressure sustaining feature, scours and cleans the pipes which reduces corrosion and improves the water quality.

SEAMLESS INTEGRATION

In order to reduce the physical appearance of an industrial device in front of someone’s home, a valve box is used to conceal and protect the flushing unit. Each location has a custom poured slab with the discharge tied directly into the subsurface drainage system so as not to cause unsightly or hazardous conditions. Each unit includes a water sampling port so that onsite clarity and testing can be easily seen and sampled without disrupting the process.

Due to the depopulation of the parish, the water system has too much water to routinely turn over in twenty-four hours as it did pre-Katrina. With spotty redevelopment, they cannot turn off sections of the system, rather they need to determine where the water flows and how fast it takes to get there in order to affect a flow pattern change. To do this they have 2,000 reference points for pressure calculations that measure the mean C-Factor of residual pressure loss to determine water usage. This allows waterworks operators to reduce flushing and water loss in areas when usage is high.

SMART MODELING AT WORK

St Bernard Parish has now developed a water demand model that helps fine tune flushing times. Daily data is compared with historical data to optimize decision making. When chlorine (1.0 minimum) begins to fall off, as well as Nitrite (0.4-0.5ppm) and ATP results (>10.0 count), a warning point is reached that triggers automatic flushing or heightened testing for the identified section. Once flushing is required, velocity measurement and gallons flushed are recorded for future modeling.

The parish has designed a flush cycle to create a wave action to force flush 27 miles of the distribution system as needed. “The programming is easy, the hard part is deciding how to set them so that we can use them in the best manner possible—this is where our water demand modelling proves to be valuable,” says Groby.

With regulated flush cycles and perfected velocity at each individual installation point, fresh water is effectively drawn into areas where water quality falls below acceptable levels. Flushing every dead-end in the system is vital to ensuring the removal of this poor water. The Hydro-Guard TAPS Station also has a unique pressure sustaining feature to ensure minimum upstream pressure is maintained for system needs and, in the event, that fire flow is needed.

The programming allows the Parish to activate flushing at any given time of the day or week. The best time to do this is at night when the demand is low. This prevents cloudy water, low pressure and standing water complaints that are associated with conventional high volume, daytime flushing activities. This also enables distribution of the discharged water over several hours, if necessary, by programming the units to activate for shorter multiple durations throughout any given day. “By using these flushing units, we have been able to use our greatly reduced personnel in a more efficient manner and save on our limited utility resources,” adds Groby.

SAFE WATER DELIVERY FOR ALL

Jacob Groby is an advocate of safe water delivery and speaks on the topic at many industry events. “All southern water systems that experience high temperatures (+72 degrees) need to be aware that they should be routinely flushing their water systems and using the new testing tools for all water quality indicators to ensure a consistent level of protection and maintain fresher water,” says Groby. With many states experiencing higher than normal temperatures, his message needs to be heard.

While it is common knowledge that routine flushing is an excellent solution to maintaining fresh water in a distribution system, outdated practices can amount to large losses of precious water and require many man hours if required to do manually. The Hydro-Guard TAPS automated flushing unit uses the least amount of water to get the job done and is easily programmable to minimize man hours and do much of the work during low demand, which is typically at night time.

“Our distribution system has shown a marked improvement on most factors with improved chlorine residuals, lower total trihalomethane and haloacetic acid values, plus reduced consumer complaints,” concludes Groby.

FOR MORE INFORMATION

Siemens Digital Industries Software, a business unit of Siemens Digital Industries, is a leading global provider of software solutions to drive the digital transformation of industry, creating new opportunities for manufacturers to realize innovation. With headquarters in Plano, Texas, and over 140,000 customers worldwide, we work with companies of all sizes to transform the way ideas come to life, the way products are realized, and the way products and assets in operation are used and understood. For more information, visit www.sw.siemens.com.

Mark Magda is global sales manager for Mueller Water Products. Mueller Water Products is a leading manufacturer and marketer of products and services used in the transmission, distribution, and measurement of water in North America. The company’s broad product and service portfolio includes engineered valves, fire hydrants, metering products and systems, leak detection, and pipe condition assessment. It helps municipalities increase operational efficiencies, improve customer service, and prioritize capital spending, demonstrating why Mueller Water Products is “Where Intelligence Meets Infrastructure.” For more information, visit www.muellerwaterproducts.com.

MODERN PUMPING TODAY, October 2019

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!