The Algerian Ministry of Water Resources took up a project to create a reliable supply of water to the city and area of Tamanrasset in the Sahara Desert. This water supply is important to the region as the 660 miles of pipeline and six pump stations are expected to encourage development of an urban city with agricultural perimeters. The water will come from aquifers near the city of In Salah and will be transported through a pipeline with a capacity of 26.4 million gallons per day.

THE CHALLENGE

The Algerian Government awarded the contract for the execution of the project to a Chinese contracting company, which approached one of Sulzer Pumps’ customers to tender the entire order for pumping units. With only limited experience in water pipelines, the Finland-based engine manufacturer contacted Sulzer Pumps for tendering support. Based on the successful execution of joint projects for oil pipelines in the past, our Finnish customer was confident we could work together to meet the challenges of the Sahara project.

THE SOLUTION

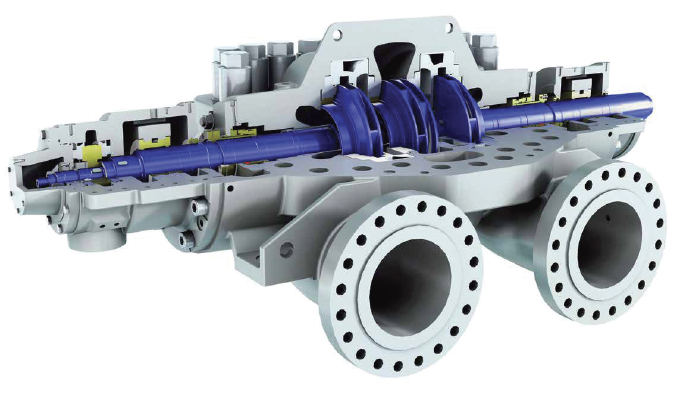

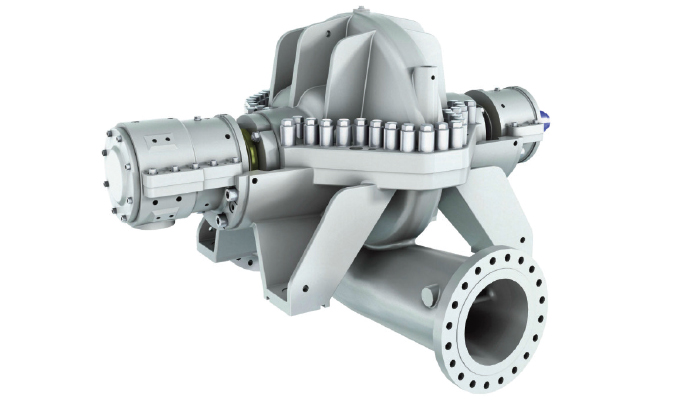

For each of the six pump stations, Sulzer Pumps proposed three axially split HPDM pumps—two in constant operation and one in stand-by—a supply of eighteen pumps in total. Sulzer Pumps has the experience and know-how to deliver a reliable and competitive solution. Led by engineers from the Sulzer Pumps Water and Wastewater segment based in Winterthur, we worked with the customer from the beginning to develop technically optimal solutions, and worked closely with our manufacturing site in Brazil to coordinate production timing and delivery. 3D design has been used throughout the project to enable better arrangement of all accessories on the skid. Such full and fast support helped to win and fulfill the project.

HPDM axially split volute pumps are tailor-made and are extensively used to transport large volumes of liquid over long distances and high geodetic heights as in water and oil pipelines. They are available in single stage or various multistage configurations with single- or double-suction impellers.

CUSTOMER BENEFITS

Our customer received intensive engineering and tendering support from the beginning of the project. The end-user received the best hydraulic fit for the requirements, with efficient, cost-effective solutions that are easy to operate and maintain for reliable water pipeline operations.

THE SULZER DIFFERENCE

Sulzer Pumps tendering and application engineers worked towards finding the best and most competitive solution for this project. We are applying our hydraulic and mechanical experience and knowledge to provide the most reliable and cost-effective products. Continuous improvements and special designs for special needs make the range of HPDM pumps ideal for water applications.

FOR MORE INFORMATION

Sulzer’s core is flow control and applicators. The company specializes in pumping solutions, services for rotating equipment, and separation, mixing and application technology. Sulzer’s customers benefit from a network of over 180 production and service sites around the world. For more information, visit www.sulzer.com.

MODERN PUMPING TODAY, May 2019

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!