Whether it’s at product launches, factory tours, or trade shows, the staff at MPT is afforded an up-close look at the newest offerings for our industry, and each December, we look back on the year that was and present our choices for the Top Products spanning the industrial pump and rotary equipment markets.

In the pages that follow, MPT shares its selections for the products that speak to the industry’s needs for efficiency, reliability, and innovation. Each of our Top Products was chosen through submissions from our staff, advertisers, and readers like you. The products range from large multinationals you’re likely familiar with to smaller, regional suppliers worthy of your attention.

Regardless of their size or reputation, they all offer value you can take into the new year. Enjoy!

AUTOMATIONDIRECT

Stratus Vortex Cooler Kits

AutomationDirect has added complete vortex cooler assemblies to its enclosure thermal management lineup. New Stratus® vortex cooler kits include everything needed to implement enclosure cooling. The kits include Stratus vortex cooler with distribution tube and muffler, a Stego adjustable thermostat, a NITRA pneumatic filter/regulator with NITRA 5-micron filter element and a NITRA two-way, two-position solenoid valve. Stratus vortex cooler kits are priced at $349.

Stratus vortex coolers have cooling capacities from 500 to 2,500 BTUH; vortex cooler advantages include small physical size, cools without refrigerants (no CFCs, HCFCs), exceptionally reliable with no moving parts and vortex coolers are suitable for harsh environments.

The all stainless-steel Stratus vortex cooler mounts in a single 3/4-inch electrical conduit knockout, and relief valves and seals are built-in which enable the units to maintain the sealed nature of NEMA 4, NEMA 4X, and NEMA 12 enclosures.

For more information, visit www.automationdirect.com/enclosure-vortex-coolers.

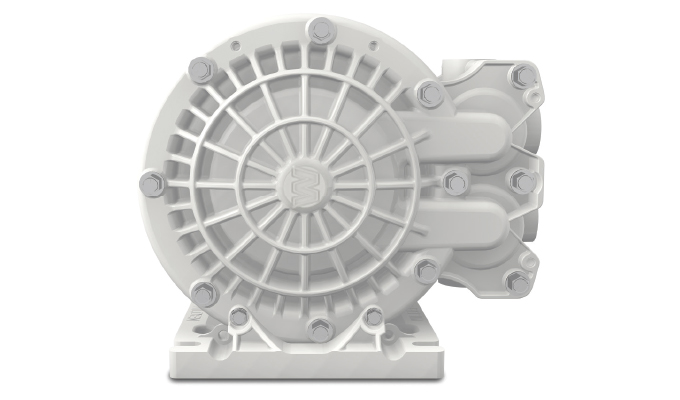

WILDEN®

V150 Velocity Series Pump

Featuring a unique detachable mounting foot, Velocity Series pumps can easily be reoriented into a vertical or horizontal position with multiple inlet and discharge port options. With this innovative and versatile design, the pump can be installed in multiple orientations, a critical consideration for systems and skids.

The Velocity Series features a bore-seal design that eliminates leaks that can result from torque decay. In addition, Wilden Velocity Series pumps incorporate a proven and simple air distribution system (ADS) with only two moving parts that reduces the risk of downtime for long-term reliability.

Velocity Series pumps are available in polypropylene and PVDF construction, as well as an Accu-Flo™ (solenoid) option, with elastomer options that include PTFE and Wil-Flex™. Velocity Series pumps feature an interchangeable footprint with previous Wilden designs (P.025, P25, P1, and P100) for user convenience.

For more information, visit www.wildenpump.com.

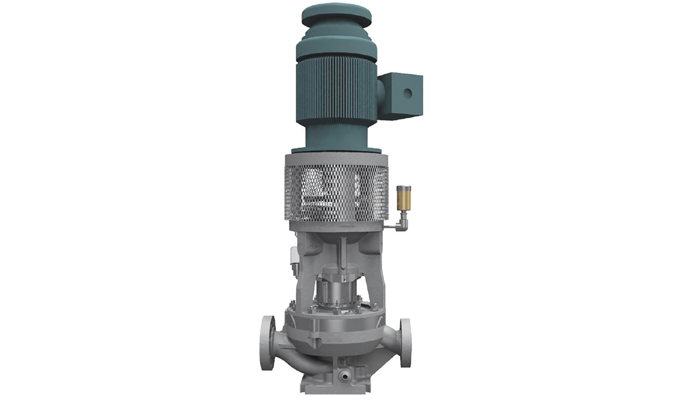

SUNDYNE

LMV 801 Direct Drive Centrifugal Pumps

This year Sundyne delivered a series of upgrades to its line of LMV 801 vertical direct drive centrifugal pumps, which are used in a wide range of applications across the upstream oil and gas, midstream gas processing, and downstream refining, petrochemical, and general industrial markets. New enhancements include:

New additions to the line of LMV 801 direct drive pumps include:

801CS (API 682 Cartridge Seal) is a self-contained unit consisting of a shaft sleeve, seal, and gland plate that fits seamlessly onto the pump shaft as a single assembly—providing a convenient and economical alternative to standard seals, while also eliminating errors in installation while preventing many of the common causes of seal failure.

801S (API 685 sealless magnetic drive) combines the hydraulics of Sundyne’s direct-drive pumps with the magnetic drive technology pioneered by HMD/Kontro 70 years ago.

Flexible Mechanical Seal and Sealless Configurations mean any LMV-801 pump can be converted in the field to an ultra-reliable, API 682 cartridge seal, or leak free API 685 sealless magnetic drive configuration.

For more information, visit www.sundyne.com.

GAS CLIP TECHNOLOGIES

Multi Gas Clip Simple Plus

Introducing Multi Gas Clip Simple Plus, a new portable four-gas detector with three-year continuous run time. Once activated, this unique multi-gas detector is warranted to provide rapid gas detection 24/7 for three full years. Just turn it on and it’s good to go. Gone are the days of charging your multigas detector every day. This detector never needs charging. Continual calibration is not necessary either. Battery and sensors last the life of the detector. It even detects in oxygen-depleted or oxygen-enriched environments. Reliably test for hydrogen sulfide (H2S), carbon monoxide (CO), oxygen (O2) and combustible gases (LEL) with this simple-to-use and simple-to-maintain detector.

Audible, visual, and vibrating alarms alert instantly when the gas level you set is detected. From the moment gas is detected, until it is no longer present, data is stored on the detector in one second intervals providing the full picture of an event. Bump tests and calibrations are also stored. Full access to this needed information is available to your management team using a laptop or computer and a GCT IR Link or MGC Simple Dock. Data is automatically formulated on a simple-to-read Excel spreadsheet, which saves you the unnecessary expense of outside record maintenance.

What makes this ultra-durable detector able to perform this well for this long even under the harshest of conditions? The secret is the sensor technology. The MGC Simple Plus uses energy-efficient Infrared Sensor Technology inside the LEL combustible gas sensor. Gas is detected with an infrared beam of light which doesn’t require the presence of oxygen and doesn’t rapidly drain the battery enabling the battery to last for years instead of hours. The infrared LEL sensor is immune to sensor poisons eliminating the need to regularly calibrate to offset signal loss. The sensor won’t burst if suddenly exposed to high gas levels and it doesn’t contain fragile parts that can easily break. Operation is fail-safe. All these features add up to a durable and dependable detector that lasts for years and years.

Gas Clip Technologies’ continued development and refinement of advanced low-power photometric infrared technology for LEL measurement found in this newest member of their gas detector family makes gas detection simpler and safer than ever! Detectors are available through distributors worldwide.

For more information, call 972.775.7577 or 877.525.0808, email info@gascliptech.com, or visit www.gascliptech.com.

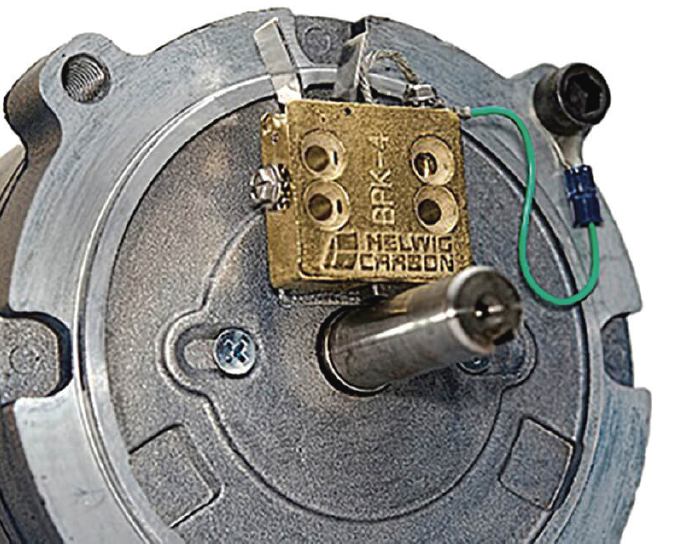

HELWIG CARBON

BPK-4 Bearing Protection Kit

Premature bearing failure is a major cause of motor downtime and costly repairs. Helwig Carbon uses proven carbon brush technology in a variety of bearing protection kits for motor shafts. Helwig Carbon kits effectively divert induced electrical currents away from the bearings, protecting them from damage and failure.

Helwig Carbon’s bearing protection minimizes shaft voltage and electrical noise. When comparing induced shaft voltage with the Helwig BPK-4 versus a carbon fiber ring, lower value equals more effective bearing protection. Peak-to-peak voltage for Helwig’s solution is more than five times lower than the fiber ring, which significantly reduces the risk of current flowing through the bearing.

For more information, visit www.helwigcarbon.com.

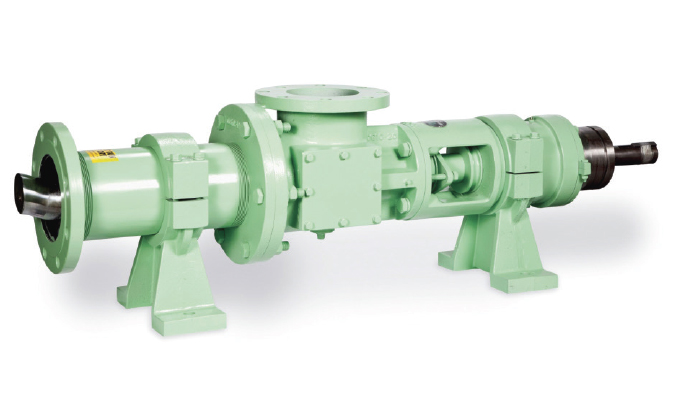

CONTINENTAL PUMP COMPANY

Gear Joint Pumps

A Crown Gear Joint Pump, like Continental’s CG and CK Models, are designed to handle the heavier applications of sewage, industrial waste, polluted liquids, and slurries. It consists of a splined connecting rod with a ball and ring gear, along with front and rear thrust plates which help make a very strong connection between the rotor and drive shaft.

For more information, visit www.continentalultrapumps.com.

MELTRIC

DSN Series Electrical Connections for Pumps

Meltric’s DSN Series switch-rated plugs and receptacles with Decontactor™ technology and push-button circuit disconnection provide exceptional safety and convenience. Type 4X/IP69 environmental ratings help ensure watertight connections; ideal for wet or wash-down environments. Silver-nickel contacts, stainless steel components, and chemical resistant housings help withstand corrosion. Butt-style pressure contacts ensure excellent electrical connections even in dusty or dirty environments. DSN devices are UL/CSA switch- and HP-rated; available in models from 20-150 amps. Lockout/tagout capability and optional integral pilot contacts help make plant operations safer and more efficient.

For more information, visit www.meltric.com.

SULZER PUMPS

BLUE BOX™ Data Analysis Package

Operators of large-scale pumping systems face a number of challenges, not least minimizing energy and maintenance costs. Sulzer’s BLUE BOX. a recent development in data analytics aims to provide real-time information on pump performance.

Pumping installations require large amounts of energy to drive the pumps, so any improvement in efficiency or availability will have a significant effect on the revenue and profitability of the operation. As one of the world’s leading pump manufacturers and an expert in maintenance, repair and retrofit solutions, Sulzer is at the forefront of pumping technology. The most recent development from the company is an advanced data analysis package that uses existing data to identify assets that would benefit from repairs or adjustments in design to make them more efficient. Known as BLUE BOX™, this innovative solution leverages the Internet of Things (IoT) and uses expert analysis to support asset investment decisions.

OPTIMIZING EFFICIENCY

Pump performance is determined by many factors, not least the design and suitability to the application. In the first instance, this will be an ideal match, but conditions change over time. However, there comes a point where the performance, and therefore the efficiency, of the pump is beyond the preferred range. The challenge is to determine the ideal time to take the pump out of operation and implement the necessary changes to make it more efficient. This “break-even” point occurs when the maintenance costs are outweighed by the cost of lost production due to the lack of pump performance.

OPTIMIZED DECISION MAKING

BLUE BOX is designed to analyze existing data, creating a comprehensive performance picture for every pump in a process and identifying weak points in the chain. Better utilization of historical data that already exists, coupled with a live data stream, enables the software package to optimize the decision-making process. This enhances the predictive maintenance model by allowing assets and personnel to be in place when a repair or retrofit project is undertaken.

SIMPLE IMPLEMENTATION

All large-scale pumping installations have a continuous stream of telemetry data that is processed by a supervisory control and data acquisition (SCADA) system and programmable logic controllers (PLCs). Gathering this live and historical data directly or via a process historian and combining it with geometry and simulation data enables a complete digital twin representation of pump and system performance to be created. Using a secure access link, BLUE BOX passes the existing data through its advanced analytics engine to create visualizations and trends of all pumping assets.

REAPING THE BENEFITS

The additional insight by BLUE BOX enables operators to have a better understanding of pump performance, efficiency and reliability on both an individual and collective basis. Single-digit improvements in efficiency can make savings that deliver a major contribution to overall cost reduction. By making better use of existing data resources, applying expert analysis and years of pump design expertise, Sulzer has created a flexible solution that enables better decision-making and has the potential to save millions of dollars for operators.

For more information, visit www.sulzer.com.

LOVATO ELECTRIC

ADXL Series Soft Starters

Soft starters are the best performing solution among reduced stator voltage starting devices. LOVATO Electric’s new 30 A to 320 A ADXL series performs two-phase control and provides advanced features for motor starting, stopping, monitoring, and protection. The current transformers (CTs) in ADXL devices constantly monitor the current and their control algorithm keeps the currents on the individual phases well balanced during starting and stopping. The ADXL series, with the two-phase control technology, is a compact and competitive solution that ensures high performance in all applications.

The new two-phase ADXL soft starters add torque control and the kick start function. The torque control provides motor starts with very gradual acceleration and deceleration: this drastically reduces mechanical failures and transmission wear. Kick start is the function that makes it possible to start a motor when the initial torque is not sufficient to overcome the initial friction forces, providing high torque in the very first few moments of start-up.

For more information, visit www.lovatoelectric.com.

BELL & GOSSETT

Parallel Sensorless Pump

Xylem Inc.’s Bell & Gossett brand is introducing its Parallel Sensorless Controller, a device that provides advanced system staging of up to eight pumps in parallel configuration to maximize system efficiency—an industry-leading offering with a large 5.7-inch touch screen that displays real-time feedback and enables energy modeling.

Sensorless pump control technology relies on pump-specific algorithms, which can accurately predict where a pump operates on its curve. Using speed, torque and power data to know where the pump operates on the curve, sensorless pump controllers can be set up to take action based on those factors.

The staging and destaging multi-pump configurations that are compatible with the Parallel Sensorless Controller are created on the basis of efficiency, thus allowing optimized hydraulic efficiency. It meets ASHRAE 90.1 system efficiency requirements and features advanced system staging with B&G’s expansive Efficiency Island operating range.

With the capability to run parallel configurations with up to eight pumps, B&G’s Parallel Sensorless Controller delivers the best efficiency staging to minimize energy costs and enables individual pumps to take control if one or more units or sensors are not active, ensuring reliable system flow and pressure.

For more information, visit www.bellgossett.com.

WINDROCK

Spotlight Monitoring System

Leveraging IIoT principles to deliver insights into the health and performance of critical assets, the new Spotlight Monitoring System is a plug-and-play solution that utilizes four magnet-mounted PUCs (Peripheral Universal Connection) to acquire high-speed rotating data. These PUCs are connected to the Spotlight Controller, considered the central nervous system, via a single cable. The Spotlight Controller then sends the data over to a Microsoft® Azure hosted cloud via gateway provides actionable insights and uncovers trends concerning the health of the entire fleet of assets. In addition, Windrock’s Spotlight Monitoring System allows for tiered services to enable digital transformation.

For more information, visit www.windrock.com.

BLACOH SURGE CONTROL

Hybrid Valve

For metering pumps, Blacoh’s new Hybrid Valve is the first combination pulsation dampener and back pressure valve in one. The combination eliminates common issues with installation, saves on space, and reduces the number of leak points. The quick-opening effect of a normal back pressure valve can create too much gain within the back-pressure valve resulting in inefficiency and chatter. The Hybrid Valve has been designed so that there is no chatter. Blacoh Industries is a woman-owned business and ISO 9001:2015 certified.

For more information, visit www.blacoh.com.

ANUE WATER TECHNOLOGIES

Phantom Series for Municipal and Industrial Markets

The Phantom system utilizes side stream wastewater to draw in concentrated oxygen and ozone. The aerated/ozonated side stream is delivered back to the wastewater force main, or wet well / lift station through AWT’s patented EP or HS well washing systems, uniformly transferring the oxygen and ozone for both FOG and odor / corrosion control. The technology is particularly well suited to high traffic areas or neighborhood locations requiring a small profile and an esthetically clean and attractive solution.

The Phantom system can also be utilized for small municipal TOC applications. Each system is engineered to meet the plant’s specific performance requirements. Another key benefit are the low capital and operating costs. The capital cost for the Phantom system is less than $90,000, and the operating cost is typically less than $10 per day.

For more information, visit www.anuewater.com or email Tonya Chandler, vice president of sales and marketing, at tchandler@anuewater.com.

PULSAFEEDER

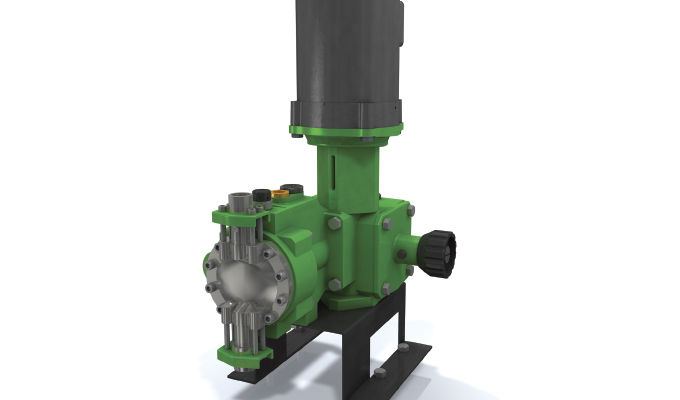

PulsaPro Metering Pumps

After the largest voice-of-the-customer exercise in the history of the company, Pulsafeeder’s API-675 compliant PulsaPro diaphragm metering pump series offers a variety of enhancements that simplify commissioning and start up, enhance the pump’s ability to survive upset conditions, and reduce the pump’s footprint.

A new push-to-purge valve maintains hydraulic balance by automatically removing air entrained in the hydraulics. A high-performance valve reduces maintenance costs and provides resiliency against system upsets. A new Hydraulic Bypass Valve protects the pump from over-pressurization. The new four-bolt tie bar resists connection forces and pipe stress by providing rigidity to the check valves and facilitating removal of the check valves without breaking the piping. A redesigned three-component check valve system (fluted valve guide, gravity seating check valve, and knife edge seat) ensures accuracy and longevity. And a new diagnostic window provides a visual indication of the pump’s performance, operation. and diaphragm integrity.

Pulsafeeder Hydraulically Actuated Diaphragm pumps are designed to simplify operation and maintenance—and they ensure dependability with a five-year drive train warranty.

For more information, visit www.pulsa.com.

WEIL PUMP, A WILO COMPANY

Weil Booster Systems

Weil Pump now offers a full line of vertical multistage booster pumps and systems. The new booster systems combine Weil’s Programmable Logic Controller (PLC) panels with Wilo-Helix V pumps and are available in two-, three-, or four-pump configurations. The multi-pump systems offer real-time diagnostics and remote monitoring with variable speed control and balanced run time for each pump. The booster packages are suitable for many applications, including water supply, pressure boosting, agriculture, washing/sprinkling systems, cooling circuits, and condensate return.

Weil’s PLC panels are built in-house at Weil’s production facility in Cedarburg, Wisconsin, and provide a powerful platform for the control of most pumping systems, including commercial, industrial, and process and booster service pumps. The panels feature an easy-to-use, seven-inch touchscreen and offer onboard ModBUS and optional BacNET and LonWorks interface. Additionally, the panels boast full-system kWh energy reporting with detailed metrics, built-in troubleshooting, and alarm histories for offsite management and control.

Weil’s booster pump offering also includes the Wilo-Helix V high-pressure vertical multistage centrifugal pumps as well as Wilo-Helix EXCEL high efficiency multistage pumps.

For more information, contact Sarah Morris, marketing communications specialist, at 888.945.6872 ext.219 or at sarah.morris@wilo-usa.com.

LIBERTY PUMPS

LSG-Series Omnivore® Grinder Pumps

The Omnivore® Series of grinder pumps by Liberty Pumps meet the demanding needs of commercial and residential sewage applications where difficult solids-handling is crucial. With thousands of units installed globally, the Omnivore has a proven track record in a variety of applications, including homes, motels, schools, shopping centers, and lakefront communities.

The pumps feature patented V-Slice® Cutter Technology developed by Liberty’s own engineering team. This new innovation provides more cuts per revolution for superior shredding performance in demanding sewage applications. The hardened stainless-steel cutting system aggressively shreds, jeans, shop rags, diapers, sanitary napkins, and other difficult solids into fine slurry with less jamming than other cutter designs. A unique open volute eliminates the traditional cutwater found in other pumps—improving solids flow and reducing potential jamming of material in the volute. Other features include a one-piece cast iron body, quick-connect power cord, stainless steel impeller and dual shaft seals. Models are available in single stage or two stage designs—providing maximum pumping heads to over 180 feet. Complete pre-designed grinder systems are available in a variety of basin sizes and backed by Liberty’s three-year limited warranty.

For more information, call 800.543.2550 or visit www.libertypumps.com.

VAUGHAN COMPANY

Conditioning Pumps

Vaughan Company’s Conditioning Pumps eliminate grease mats and contribute to less of those costly vacuum truck visits in the process. Lift stations and collection pits tend to form floating mats that standard lift station pumps cannot pump out. If left unattended, the layer will continue to thicken until, eventually, a vacuum truck is required to suck out the thick layer. Over time, the frequent vacuum truck calls can result in thousands of dollars of maintenance and dumping fees. Alternatively, incorporating a Conditioning Pump to effectively handle solids and mix the pit can help bypass the frequent service calls and contribute to a more cost-efficient lift station.

Conditioning Pumps are a submersible chopper pump mounted on a portable stand and fitted with a high-velocity mixing nozzle. These pumps recirculate the contents of a wet well while chopping and mixing to produce a homogeneous mixture that is more easily pumped out. The Conditioning Pump can be placed in the wet well to chew up all of the rags, wipes and solids so that the existing pump won’t get clogged.

For more information, visit www.chopperpumps.com.

IWAKI AMERICA

IX Series Advanced Metering Pumps

IWAKI, a worldwide leader of high performance chemical handling, dispensing and control equipment, is proud to introduce the IX-B metering pumps, significantly expanding their IX Series line of advanced metering pumps. Four new models offer an output range down to 0.002GPH, creating a full pump line with capabilities from 0.002GPH to 80GPH and pressures up to 250PSI in eight models.

The IX Series are direct-drive, digitally controlled metering pumps combining both accuracy and flexibility into a low-power, energy efficient design. Using sophisticated BLDC motor control technology, precise control is maintained over a wide output range, enabling a small product range to satisfy a broad range of application flow rate requirements. The IX Series meets today’s demands for automated chemical delivery in industries from wastewater treatment and chemical process to agriculture and food processing.

The new IX-B pumps retain all the advanced features of the existing IX family. Fully programmable inputs enable the pump to be controlled via analog, digital, or ProfiBus communication with additional standard remote control and alarming features. A high turndown capability coupled with an accurate 1% repeatability enable few pumps to cover a wide range of applications. The patent pending degassing design of the pump end coupled with the drive design enable the pumps to continuously purge gas in the system through the pumps—eliminating one of the most common pump problems. By design, the IX series pumps are extremely energy efficient and include advanced safety features, such as built-in leak detection, ensuring continuous pump operation.

The IX-B pumps include both functional and convenience enhancements ranging from new diaphragms to flexible installation and mounting abilities. An all new solid PTFE diaphragm improves overall chemical resistance and helps expand applications. A completely redesigned control unit enables the display/keypad location and orientation to be customized on-site to suit the installation. The status of the pump is easily viewed in dark locations or from a distance with a large multi-color LED indication bar mounted in the top of control unit. The pump mounting base quickly converts to a wall mount bracket for more convenient installation options. The flexible liquid connection options now include tubing connections. All the features in the IX-B pumps combine to provide tremendously versatile solutions in a small package.

For more information, visit www.iwakiamerica.com.

ADEDGE WATER TECHNOLOGIES

WaterPOD Containerized Treatment Units

WaterPOD Containerized Treatment Units from AdEdge Water Technologies have been developed to meet the growing U.S. and International demand for small footprint, cost-effective modular water treatment installations. The fully integrated, pre-engineered, pre-wired, packaged water treatment solution combines system performance with economy resulting in an ideal solution for sites where space, cost, and schedule are critical.

WaterPOD modular enclosures contain one of AdEdge’s many types of Packaged Units, or APUs, treating a wide variety of contaminants for drinking water, remediation, or industrial/commercial applications. Provided in either 20-foot or 40-foot lengths, the WP-20 or WP-40 units can be single, double, or multiple units combined to accommodate design flows of up to 2,000 or more.

The treatment systems are designed, custom built, and delivered inside the pre-manufactured and customized water tight enclosure. The unit is constructed of painted carbon steel with coated steel overlay on the wooden floor and can include multiple other customizable options including insulation, lighting, ventilation, pedestrian doors, windows, HVAC unit to meet site specific and weather requirements.

For more information, visit www.adedgetech.com.

GORMAN-RUPP

SF Series®

Gorman-Rupp SF Series® submersible solids-handling pumps are designed to provide you with the ultimate in pumping performance. All SF Series pumps use NEMA Premium Efficiency motors and pass a minimum 3-inch spherical solid. Vortex pumps use the patent-pending Staggerwing® impeller technology.

SF Series submersible solids-handling pumps are available in slide rail and construction / trash versions for use in most liquid removal applications. The SF Series comes with 3-, 4-, 6-, and 8-inch flanged discharge and power ranging from 3 to 75 horsepower (1.5 to 56 kW). These combinations will provide flows up to 3,100 gallons per minute (195.6 lps) and heads to 190 feet (57.9 meters). Built to the same exacting standards you’ve come to expect from our industry-leading self-priming pumps, SF Series pumps are designed for easy maintenance and constructed for long life.

For more information, visit www.grpumps.com.

CRANE PUMPS & SYSTEMS

SITHE Submersible Chopper Pumps

SITHE chopper pumps are the Barnes solution to clogging in highly demanding solids laden waste water applications in the Municipal market. SITHE chopper pumps are available in 4- and 6-inch discharge sizes from 7.5 to 60 horsepower. SITHE chopper pumps provide a maximum head of 200 feet and a maximum flow of 1,750 gallons per minute. Both standard and explosion proof SITHE chopper pumps are available in industry best lead times of three weeks.

SITHE submersible chopper pumps solve the largest problem faced by customers in the waste water industry—clogging. SITHE chopper pumps solve clogging issues by using a unique first-of-its-kind chopping design. The design consists of an open center cutter, heat treated 416 stainless steel blades and the industry’s lowest clearance between the stationary and rotating blades.

Other market defining features of the SITHE chopper pump includes highly efficient Barnes hydraulic designs, dual/tri voltage plug-n-play quick connect cords, liquid cooled motors, class H insulation, 416 stainless steel shaft with a tapered fit, readily available premium quality mechanical seals, heavy duty bearings, large lifting bails, and stainless steel hardware.

These premium features of the SITHE chopper pump provide immense value to customers like superior non-clogging and solid size reduction capabilities, high reliability, ease of maintenance, good hydraulic coverage, and low lifecycle cost.

KEY PRODUCT CHARACTERISTICS AND BENEFITS:

- Heat treated chopper blades and open center cutter design

- Explosion proof design – Class 1, Division 1, Groups C & D, T4

- Variable frequency drive rated Class H varnish and magnet wire

- Plug-n-play “quick connect” cord with integral temperature and moisture sensors

- Simplified maintenance

- CSA certified

- Double mechanical seals and heavy duty oil lubricated bearings

- Stainless steel lifting bail and hardware

For more information, visit www.sithechopper.cranepumps.com.