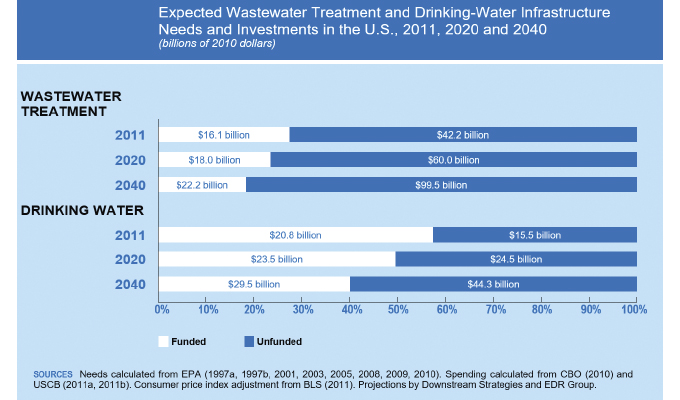

An act that provided incentives, penalties, as well as funding for communities to clean their water, the Clean Water Act (CWA) was passed in 1972. The Environmental Protection Agency (EPA) at the time estimated that over two-thirds of the waters in America were unfit for fishing or swimming; a number that was cut in half after the CWA was established. Almost fifty years later the early success of the program has declined. A combination of funding cuts, aging infrastructure, and new pollutants has pushed the responsibility for water treatment back upstream to the facilities that produce the wastewater.

Historically, large centralized publicly owned treatment works (POTW) were the beneficiaries of the CWA. Funding and regulatory changes made investment in these POTWs beneficial for the communities and production facilities that used their services. The American Society of Civil Engineers issued a D+ grade to our nation’s POTWs in 2017. Our POTWs throughout the country continue to fail. Production facilities will be required to manage their water use and discharge more efficiently and effectively because the local POTW cannot handle the water flow and/or the contaminant loading.

FACILITY DRIVERS

The reality is that the burden of water treatment is moving away from the centralized POTW and further upstream to the production facilities. While production facilities have always focused on optimizing their operations to maximize profits, they have now added a water treatment cost center. This adds operational costs; it does not improve profits.

More importantly, water treatment is not typically a facility’s core competency. Yet, the same business considerations that a facility considers for their operations and stakeholders are the same considerations that impact their water treatment:

- Quality and brand protection

- Food safety and regulatory compliance

- Environmental compliance

- Sustainable development goals

- Profitability and productivity

- Asset protection

- Worker safety and liability

DEVELOPING YOUR HOLISTIC ROADMAP

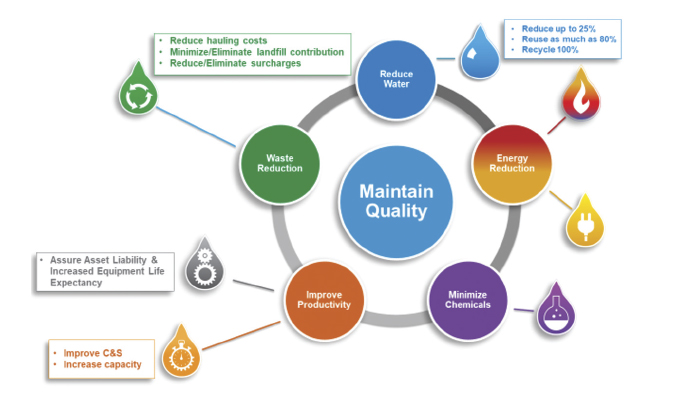

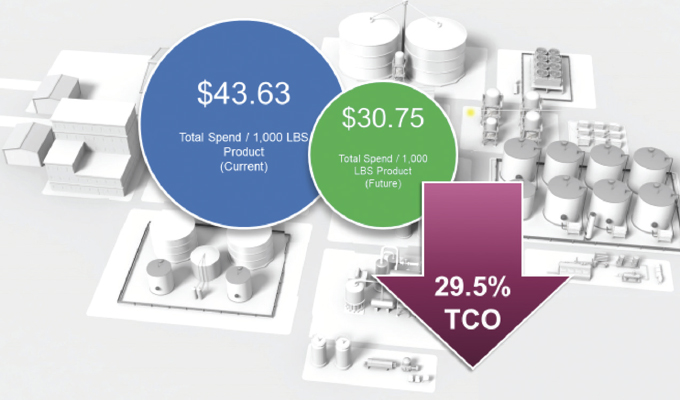

Commoditized water treatment chemicals and services is no longer a model that works effectively. Gone are the days where a buyer at a facility makes decisions based on cost per pound or cost per month for water treatment. Corporations are looking for an experienced business partner in their water treatment approach. An approach that includes working with on-site engineering, EHS, maintenance, management, procurement, and executives.

The development of the roadmap starts with a comprehensive site assessment (CSA). This includes discussion with your company’s stakeholders to determine local and corporate key performance indicators (KPI’s), a facility assessment, evaluation, and ways to implement. The assessment results in sharing sustainable best practices and opportunities for integrated solutions; specific to your facility and generally applicable to your organization. The assessment combines local facility expertise and insight with the assessment team’s water business expertise. In many instances, the CSA improves communication between departments and organizationally—effectively breaking down operational silos. For example, when the sanitation manager can be shown the impact a change in the cleaning and sanitation process has on the liquid solids separation operation, it helps facilitate change.

The CSA establishes the roadmap. The recommendations and implementation of items from the CSA become specific directions to achieve operational excellence. That is why developing a holistic roadmap to your water treatment matters. It results in the following:

- A comprehensive facility approach to water treatment versus department by department. For organizations with multiple facilities, it allows the facility to meet corporate goals and key performance indicators (KPIs) and prioritize capital funding and operational budgets.

- Specific solutions to meet desired goals that can be adjusted to meet production, scheduling, or business changes at your facility.

- A standardized approach that improves internal communication and goal setting.

CONCLUSION

POTWs will continue to struggle to meet their community needs and will require additional household funding to make necessary upgrades and repairs to their infrastructure. This will likely increase the financial burden on industrial users (production facilities). Getting a head start on establishing a holistic roadmap to your water treatment is the prudent thing to do.

FOR MORE INFORMATION

Daryl Mandoza is a product manager for wastewater treatment solutions at Kurita America, specializing in liquid solids separation. As part of the Kurita Group, a leading industrial water solutions provider in the world, Kurita America brings innovations to market through a unique, customized water management approach called the Kurita Way. The Kurita Way embodies complete water harmonization through a consultive engineering engagement. By incorporating all aspects of our customers’ facility, including chemical, mechanical, and operational components, Kurita America gets to the root cause of customers’ most complex challenges to deliver optimal results and overall lower cost of ownership for a better, more sustainable world. For more information, visit www.kuritaamerica.com.

MODERN PUMPING TODAY, March 2023

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!