ZAPS Technologies manufactures automated, real-time water quality monitoring equipment in support of professionals involved in water treatment, water analysis, and environmental monitoring. The engineers and scientists at ZAPS have combined hybrid multispectral analysis (HMA)—an optical methodology which requires no reagents. The LiquID™ station, a unique stand-alone instrument uses HMA combined with state-of-the-art data analysis software and web-enabled information delivery to run unattended 24/7 while producing thousands of tests per day on flowing water from raw wastewater to finished drinking water, and water from rivers, lakes and marine environments.

THE TECHNOLOGY

Hybrid Multispectral Analysis (HMA) is a unique combination of advanced optical, photonic, and statistical technologies applied to the challenge of providing synchronized high frequency data for complex water types.

Those raw signals are then automatically processed into actionable information by sophisticated computer algorithms in the LiquID, which identify the presence and measure the concentration of a broad array of substances of interest in the sample flow. This information is then delivered to the LiquID station’s secure user interface or transmitted to a SCADA system for analysis by authorized plant personnel.

This type of information is required to control treatment processes in real time. HMA allows plants to continuously adjust treatment based on current and on-line historical data to eliminate over and under treatment, provide real time water security, and facilitate compliance with and more effective enforcement of environmental laws.

THE ADVANTAGES

In this way, a continuous, high-resolution historical data record for the LiquID station’s monitoring location- encompassing months or years of minute-by-minute measurements is created, covering each of the different parameters that the LiquID station has been programmed to monitor. Spike anomalies and sudden process upsets, as well as diurnal shifts in (for example) influent composition and seasonal trends in water quality, become easily visible.

Because that information was determined quickly and automatically by HMA through the LiquID station instead of by indirect inference, time-consuming wet chemical bench analysis or bacterial incubation protocols, the timeliness, cost-effectiveness, and integrity of the data are improved.

And because the LiquID station eliminates the need for manual sampling transport and analysis of water samples, it allows permit-holders to focus their resources more directly on protecting human health and the integrity of watersheds and aquatic ecosystems. It also facilitates better process control by placing each data point in the context of the active process, thus ensuring compliance with wastewater treatment regulations and enabling more timely and effective process management.

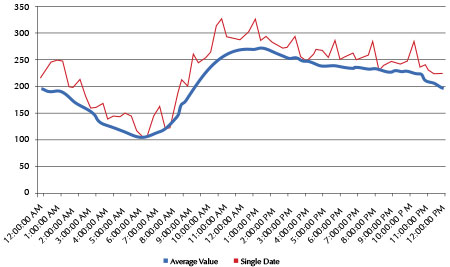

Figure 1: Raw influent cBOD data for Nov. 15, 2013 compared with annual average.

POULTRY PROCESSING WASTEWATER

Poultry processing plants convert live birds into packaged meat products for commercial sale. Significant quantities of water, about 7 gallons (26.5 liters) per chicken (Northcutt and Jones, 2004) are typically used in processing plants to wash the meat, remove and transport offal, and for cleaning and disinfection of process machinery.

Poultry processing wastewater (PPW) contains uncollected blood, solubilized fat, urine, and feces, and exhibits levels of BOD, cBOD, TSS, E.coli and nitrates that can be ten times the strength of sanitary wastewater. As such it can require treatment prior to discharge, either by treatment facilities on the premises of the processor or by municipal wastewater treatment facilities nearby.

Those facilities are hence at risk for BOD shocks and process upsets should an unexpected PPW load suddenly present in the influent matrix. Note also that PPW strength can spike much higher than average levels if a blood or offal spill occurs within the processing plant and enters the plant’s effluent stream, or when wastewater from specific plant operations is accumulated over an operating shift and then batched out into the effluent.

CASE STUDY:

DETECTION OF POULTRY PROCESSING EFFLUENT

A poultry-processing facility in Corvallis, Oregon, produces corn dogs from pre-processed chicken meat, and discharges its effluent into the wastewater collection network leading to the local wastewater treatment facility. Because the poultry processor does not work with live birds, their PPW stream contains no offal, feces or feathers but does contain significant amounts of meat juice from the grinding and extrusion lines that make the corn dogs.

The Corvallis, Oregon, Municipal Wastewater Treatment Facility is equipped with multiple LiquID stations including one to monitor the contents of the raw influent matrix and another to monitor the Facility’s final effluent. According to Dan Hanthorne, the facility’s manager, process operators who were studying the readings from the influent monitoring LiquID station in 2013 noted transient increases in cBOD and TSS readings with a repeat time of about two hours. Each two-hourly surge in cBOD and TSS stood out in the data as a distinct event. For example, figure 1 shows a single day’s worth of raw influent cBOD data (in red) in which the two-hour spiking pattern is particularly apparent. The blue line is a year-long average of one-day cBOD readings for comparison. The vertical axis is cBOD in mg/liter.

ROOT CAUSE

Armed with this data, the wastewater treatment facility operators were able to back-trace the cBOD and TSS spikes to a processing facility. Although the manufacturer had an on-site pretreatment system which was designed to remove high-strength wastes from their effluent, that system was being overwhelmed by pumped purges of hot water from the plant’s machinery cooling system which occurred at two-hour intervals. Eventually the pretreatment system was damaged by the purges, with the result being the release of extremely high-strength waste into the public sewer each time the cooling system was purged. Repair of the pretreatment system fixed the problem.

DISCUSSION

It is clear that a single composite manual measurement of the influent would not have captured these once-per-two-hour signals in the matrix. Despite the fact that the effluent from the poultry facility had a marked effect on the wastewater treatment process, the flow represented on average less than 3 percent of the total influent entering the Corvallis WWTF. The cBOD signals extracted from that influent stream by the LiquID station became visually and statistically resolvable due to the data’s reproducibility, large quantity, and high quality.

This examples demonstrates just one application of how access to real-time continuous monitoring furnished by the LiquID station allows treatment plant operators to better understand not only the processes occurring within the plants they manage but also processes that occur within the entire sewage collection and transport network. With the ability of the LiquID station to monitor over 50 distinct parameters in applications ranging from finished drinking water to raw wastewater influent in fresh or saltwater conditions there are a number of applications that can benefit from process optimization, plant stabilization and cost savings. ■

FOR MORE INFORMATION

ZAPS Technologies, Inc. is a producer of online, real-time, water quality monitoring equipment to aid professionals involved in water treatment, water analysis, and environmental analysis. For more information, visit www.zapstechnologies.com.

MODERN PUMPING TODAY, July 2014

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!