In the first part of this series, we addressed some of the basics of effective valve station planning. Continuing in that mold, let’s take a look at different customization options and the practical design considerations to consider before a valve station is installed.

CONSIDERING OTHER OPTIONS

A valve position indicator is very useful for operations personnel as it gives the ability to see the exact position of the valve during operation. If a remote signal is required this can be upgraded to a position transmitter, supplying a 4-20 mA signal via SCADA or a limit switch can be added to give an output for a position transmitter. Pressure transmitters can be added to give 4-20mA signals for both inlet and outlet pressures. This option is useful if the intention is to utilize a pressure management program in the future.

Also, consider options to give more system control. A second pilot control can be added to give the ability to have upstream pressure sustaining. This is very useful in situations where there is a need to protect the upstream from being starved of pressure by high downstream demand. If downstream surge could be an issue, a downstream surge pilot can be added to the reducing valve that will close the control valve quickly should the downstream pressure rise slightly above the pressure reducing pilot set point.

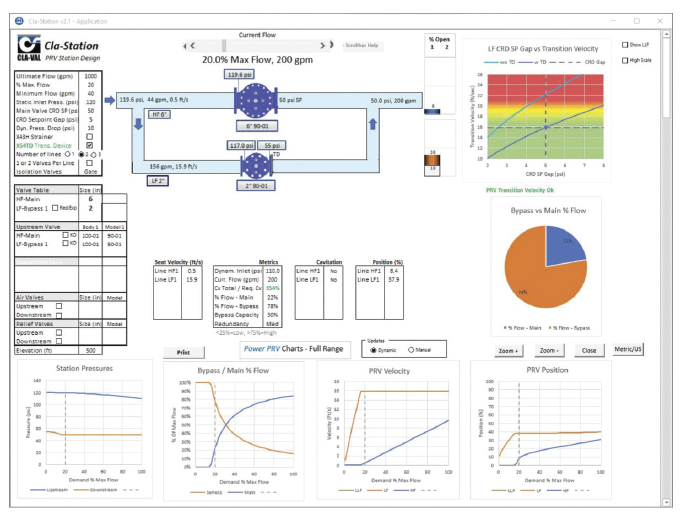

Some manufacturers will offer package solutions, for example, the Cla-Val Model XP2F offers full instrumentation that includes upstream pressure, downstream pressure, valve position, instantaneous flow, and totalized flow. When deployed across the system network the XP2F package allows for insight into pressure, leakage, flow and system distribution management. The inlet pressure, outlet pressure, valve position, flow, and totalized flow can be retransmitted to SCADA or the AMI System and logged to the internal SD Card.

The possibilities of the additions are numerous and specific requirements should be discussed with the control valve supplier to ensure you get the full benefit of all that is available.

DESIGN LAYOUT OF THE VALVE STATION

There are some key items that every valve station requires, namely isolating valves, upstream and downstream of the control valves. These are required to allow maintenance for isolating the control valve when it is necessary to work on the control valve. These valves can be either butterfly valves or gate valves and can be installed with handwheels or operating nuts depending on whether it is required to operate these valves from above ground. Most utilities will use non-rising stem gate valves as these are the valves that are typically located throughout the network so everyone is familiar with them, however, if space or cost is an issue, butterfly valves can be used, as long as there is space between the butterfly and the control valve to allow for clearance for any equipment in the control valve such as insertion strainers or flow meters.

It cannot be stressed enough the importance of protecting the control valve from foreign objects in the pipeline and this is where a line strainer is an excellent addition to the station. While most water supplies have screening at the intake point, it is common for objects to be introduced into the network, either by insufficient flushing after piping work or even open pipe ends that can attract animals during development. Everything from welding rods, fish, rodents, pieces of wood, and even expensive tools has been seen.

Each station should be installed with pressure gauges, either on the pipeline, or sometimes they are supplied with the control valve. It is necessary to know the outlet pressure to set the reducing valve, and having an inlet gauge allows the operator to see also what the conditions are upstream.

Air valves should be strongly considered for every valve station. The operation of reducing pressure naturally allows air to form in the pipeline and if this is not removed downstream of the control valve, this will move down the pipeline and potentially cause issues elsewhere. A good practice is to install an air release valve on the upstream side of the control valve—this will eliminate the possibility of air entering the pilot system, which can be a problem.

PRACTICAL CONCERNS MATTER

Lastly, some practical and functional additions are best considered before a valve station is installed as these items are easier to install before the station is operational.

- Lifting eyes in the ceilings above major pieces of equipment. If this is a concrete chamber, these need to be decided upon before the concrete is cast to ensure correct capacity, but these will make maintenance a much easier task for the operations crew.

- Spare pipeline connections, possibly for a hose bib connection. It is much easier to install before the line is pressurized.

- A sump drain. Chambers can flood and getting water out of these chambers can be an issue. This may be as simple as a daylight drain or a sump with an electric pump may be required.

- Protection for the downstream network from over-pressure. Consider adding a relief valve on the downstream piping inside the valve station.

With regard to point #4, typically, this valve will be a much smaller valve than the main line valve and an angle style is most common. The outlet from this valve will require a drain connection to eliminate the flooding of the chamber, should the valve ever be utilized. However, that is a small cost compared to the potential damage that a burst water main may cause downstream.

While a valve station design is not necessarily difficult, poor design can certainly lead to operational issues down the road. Take the time to think it through and you will win friends in the operations department later.

Mark Gimson is director of marketing and international sales for Cla-Val. As a mechanical engineer with forty years in the water industry, Gimson has a passion for expanding markets and understanding customer challenges to provide the optimal solution. Cla-Val is a world-leading designer and manufacturer of automatic control valves. From reducing and relief valves to deluge, air valves and more, Cla-Val manufactures and provides a wide variety of solutions for use in some of the world’s most demanding applications. For more information, visit www.cla-val.com.