As we discussed in part 1 of this series, the measurement of steam flow during dramatic power boiler load changes is challenge that will grow as the amount of renewable electrical energy in the grid increases in relation to the amount of electricity generated by power boilers using traditional fuels. In this month’s conclusion, we’ll take a closer look at mechanical steam flowmeters, vortex shedding steam flowmeters, and—finally—ultrasonic steam flowmeters, in addition to a brief synopsis of maintenance issues.

MECHANICAL STEAM FLOWMETERS

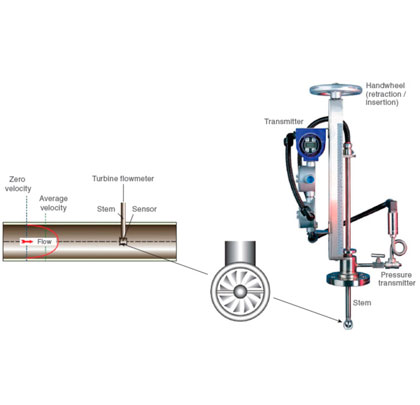

Mechanical steam flowmeters such as turbine and shunt flowmeters have been applied to steam service for decades—typically in smaller pipe sizes due to cost considerations. Insertion turbine flowmeters can often be applied cost-effectively in large pipes, can be removed from service while in service and exhibit little or no pressure drop. However, mechanical flowmeters inherently contain moving parts and bearings that can make their long-term operation and maintenance problematic due to wear and degradation. Also, insertion devices do not provide substantial accuracies due to the uncertainties associated with mounting.

VORTEX SHEDDING STEAM FLOWMETERS

Vortex shedding flowmeters are applied extensively to measure low pressure steam but their application in high pressure steam service can be limited by the operating pressure, operating temperature and pipe size. Pipe size limitations can often be mitigated using an insertion vortex shedding flowmeter that also allows removal of the flowmeter while the pipe is in service and exhibits little or no pressure drop. Because of their operating principle vortex shedding flowmeters are limited by a low flow cutoff that results in zero flow measurement below a minimum flowing velocity. This may pose operational problems in some applications.

Insertion turbine flowmeter (image courtesy of Spirax Sarco)

ULTRASONIC STEAM FLOWMETERS

Ultrasonic flow measurement systems are relative newcomers to the market with sensors now having overcome the challenges of operating at the extreme pressures and temperatures encountered in high pressure steam service.

In a steam ultrasonic meter, the flow sensor consists of a spool piece with one or more pairs of precisely positioned ultrasonic piezo transducers. Wetted sensor rods route the ultrasonic energy to the correct location in the pipe while protecting the transducers which are located external to the pipe where they can operate at lower temperature and with higher reliability than if directly in contact with high temperature steam. For high pressure service, the spool piece can be welded inline to reduce leak paths.

The flowing velocity of steam in the pipe is determined by the transit time difference between the ultrasonic energy that alternately travels with the flow stream and against the stream between the transducers. Pressure and temperature measurements are often incorporated to more accurately infer mass flow in a manner similar to differential pressure volumetric flow measurement systems.

Ultrasonic flowmeters address many of the disadvantages associated with differential pressure flowmeters outlined earlier.

The spool piece does not have any flow restrictions so there is no pressure drop.

The spool piece is constructed of materials suitable for high pressure steam and fabricated to exacting dimensions. The sensor geometry will not change over the life of the flowmeter eliminating the need for inspection to ensure accuracy.

Spool piece construction ensures that the flow element and its sensors will be installed in their proper location and examination or replacement of the sensor transducers does not require that the pipe be completely shut down. Although designed for decades of operation in high pressure steam service, the ultrasonic sensor transducers can be removed or replaced if necessary while steam is flowing—albeit using proper high temperature safety precautions.

Ultrasonic flowmeters are linear so accuracy does not degrade at low flow and accuracies are expressed as a percentage of the actual flow rate, and not of maximum range, so their accuracy is dramatically better than that of differential pressure flowmeter systems, especially at mid-range and lower flow rates.

Steam does not leave the spool piece so there are fewer opportunities for leaks as compared to differential pressure flowmeters where impulse tubing can be long and have many fittings.

Steam ultrasonic flow sensor and converter

The spool piece should be appropriately insulated for personnel safety typically at or near the spool piece.

The ultrasonic flowmeter’s velocity measurement is not affected by changes in steam pressure and temperature. For clarity, since this is a volumetric flow measurement device, pressure and temperature compensation is needed to infer mass flow from the raw flowmeter measurement.

The flowmeter is wet-calibrated at the factory so the performance statement for ultrasonic flowmeters includes the accuracy of the transmitter and its ultrasonic primary flow element and the complete meter is calibrated against a known and traceable measurement standard at the factory. A calibration certificate is provided for each meter.

Since the sensor measurement is done electronically, a wide variety of on board diagnostics are available to remotely evaluate the sensor and transmitter, as well as the actual measurement quality, at any time.

MAINTENANCE

Mechanical flowmeters with moving parts are subject to wear and bearing degradation. Differential pressure flowmeters are applied extensively in high pressure steam service but require frequent verification or recalibration to compensate for inherent drift and sensors and impulse lines should be periodically inspected to ensure they are not affecting measurement performance. Vortex shedding and ultrasonic flowmeters have no moving parts and tend to retain their geometry so as to require fewer inspections to ensure accuracy.

SUMMARY

Power plant equipment is increasingly required to respond not only to changing electrical loads but also to changing electrical supplies that include renewable power sources whose output can vary rapidly depending upon natural phenomena such as wind, sun, or clouds. These power source variations require that power boilers react faster and to a greater extent to provide reliable and stable electricity to consumers. These demands are expected to increase as renewable power generation increases in relation to the amount of power generated. Utilizing accurate and responsive high-pressure steam flow measurements are important to meet this challenge.

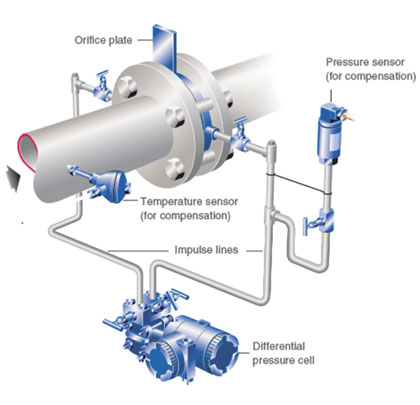

Differential pressure flowmeters used to measure high pressure steam flows have disadvantages such as pressure loss, wear over time, offset installation, periodic inspection, degraded accuracy at low flow rates, impulse lines with high pressure fluids, safety concerns due to technician error, safety concerns due to burns, transmitter pressure and temperature effects, and the accuracy of the primary flow element. In contrast to differential pressure devices, ultrasonic and vortex shedding flowmeters require less maintenance.

Utilizing ultrasonic flowmeters with wide turndowns and fast response can mitigate these disadvantages in high pressure steam service and enable power boilers to respond in a stable manner to the more extreme operating conditions and increasing numbers of startups and shutdowns in their new operating circumstances. The ability of power boilers to operate over a wider range in a stable manner can yield substantial energy savings under startup conditions and at low load. It will also tend to reduce the number of startups and shutdowns that would otherwise occur, thereby reducing operator activity reducing overall power boiler equipment maintenance.

Other possible benefits include power boiler efficiency (water and heat energy inputs/steam outputs) can be monitored more precisely to gauge or optimize boiler performance and wider turndown can readily benefit control optimization strategies during varying load conditions.

In some cases, by combining ultrasonic steam measurement with ultrasonic feed water, condensate flows and ultrasonic gas or liquid fuel flow measurement, the resulting wider operating range and accuracy improvements may allow a power generator to operate efficiently well below its otherwise rated capacity. This can result in substantial ROI if that avoids having to find a different way to efficiently generate that power, such as a lower capacity boiler. New power generation installations with these flow technologies can operate at greater efficiencies too.

If your plant uses older metering technology for steam or other flow measurements, consider the latest available ultrasonic developments to help optimize your process operations.

About the author:

Günter Pinkowski serves as director of marketing for Krohne, Inc., a world-leading manufacturer and supplier of solutions in industrial process instrumentation. Krohne offers supporting products and services for one-stop-shopping and in industries as widespread as oil and gas, water and wastewater, chemical and petrochemical, food and beverage, power, minerals, and mining and marine. For more information, visit www.krohne.com.

_______________________________________________________

MODERN PUMPING TODAY, April 2018

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!

![]()