In part one of this article, we explored pre-SCADA methods of measurement, past approaches and difficulties in measuring lift station flow rates, and the current search for more accurate measurement by today’s municipalities—who appear almost trapped by limited investment capital but increasing quality regulations. In this concluding entry, we’ll lay out some of the benefits provided by contemporary effective and environmentally-efficient flow monitoring solutions.

TUNED FLOW LIFT STATION MONITORING

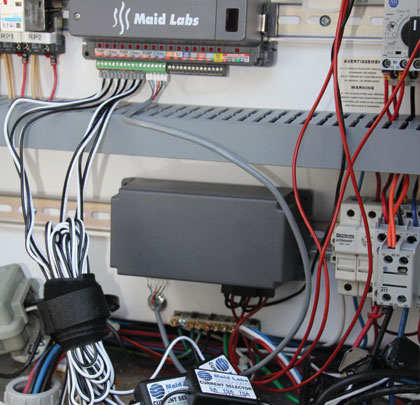

The Volucalc by Maid Labs was the first product that utilized software designed to tune pump capacities based on volumetric influent rates. This method required a data logger to store the pump cycle and volumetric data. In sampling the fill rates of the wet wells before and after each pump cycle, the software calculates pump capacities using past and future events to tune the results. This system made tuning and retuning pump capacities possible—the goal being to achieve superior accuracy. The first of its kind, this lift station monitoring system achieved overall accuracies of ± 2.5 percent.

However, ± 2.5 percent accuracy still seemed too low for a tuned-pump calculation. Although the Volucalc proved to be a breakthrough in accurately recording flow rates, the data recorded was still not exact enough. Part of the discrepancy rests with the algorithm this software hinges on. Developer Benoit Beaudoin of Maid Labs tested his algorithm with performance software that emulated typical flow rates generally seen in lift stations.

The software emulations included influent flow rates based on time of day and derived rainfall as I & I events. Beaudoin also wrote an additional algorithm within this software to imitate force main pressure variances—a critical component in calculating tuned pump capacities. The EPA did not dispute the calculation results because the product software used a bucket and stop watch approach to calculate the inflow rates and pump capacities.

Aiming to address the low percentage for tuned-flow monitoring, Beaudoin’s research found that in most current calculations, including drawdown tests, SCADA systems’ time-stamped data, which use the manufacturers’ pump curves, is just not accurate. SCADA systems derive results from a pump capacity—a capacity which does not change even though every input to calculate it does change. These calculations fail to anticipate or adjust to the dynamic effect lift stations present or the in situ pumping capacities.

LIFT STATIONS ARE DIVERSE

Wastewater flows into a wet well of many designs. Round, square, rectangular, sloped, tapered—lift station designs come in any functional shape an engineer can think up. Most lift stations collect the inflow in a wet well and pump/lift it to travel through a gravity system. Many utilities, however, use force mains or combine gravity/force main systems to transport effluent flow to be processed at wastewater plants. Variables related to pumping capacities also needed consideration; these pump capacities can vary based on size, horsepower, and type of pump(s) installed.

Also, most lift stations will experience a wide range of electrical issues from starters, contactors, alternators, and assorted relays which affect the accuracy of flow calculations. Maid Labs also found under- and over-designed station pumping capacities which impeded the force main pressures throughout the collection systems. This does not even account for the constant altering of influent flow rates or the drawdown/siphon effects on each cycle of the lift station.

Maid Labs’ MerMaid system calculates average flow rates within 2 percent of a standard magnetic flow meter.

CALCULATING MORE CONCRETE FLOW-RATE DATA

Now that the researchers understood why the tuned-flow system produced results with only ± 2.5 percent accuracy, the question shifted to how to overcome these dynamic properties for calculating more concrete flow-rate data. They knew the same old drawdown test would not be enough; it failed to account for changes in the influent rates, the force main pressures, the drawdown effect, or the siphon effect. The research and development department became obsessed with taking every small, potentially-overlooked detail into account. Developers had to adjust for the siphon effect, the drawdown effect, the possibility of mismatched pumps, the submersion of influent pipes, the capacity/volume of influent pipes—the list went on and on. Maid Labs had to do much more to their software to provide the overall accuracy desired in their products.

Past product successes worked to the advantage of researchers as it gave them the ability to review hundreds of raw data files. Armed with this information and dozens of lift station videos, the research and development team determined that the original emulation software produced calculated data too simplified to provide accurate tests. But the original algorithm Beaudoin developed was right, just limited! Starting over from scratch, Beaudoin created a new and highly versatile algorithm. What began as a single white board with the original algorithm expanded to three, then five, and now eight white boards of mathematical equations designed to continuously tune pump capacities.

The result of the team’s effort is a complex bucket and a stop watch algorithm that successfully takes the dynamic nature of lift stations and flow rates into account. The MerMaid system is a lift station performance analyzer that calculates average flow rates within 2 percent of a standard magnetic flow meter while providing critical data on the electrical performance and efficiency of the lift station in the process.

CONCLUSIONS

In addition to addressing the concerns of utilities, the MerMaid system follows EPA guidelines for cost effective and environmentally-efficient flow monitoring. On October 27, 2011, the EPA issued a memorandum with the following subject: “Achieving Water Quality through Integrated Municipal Stormwater and Wastewater Plans.” The memorandum aims to encourage utilities to use “Integrated Planning for Cost-Effective Solutions.” This plan raises the bar for utilities to meet the obligations required by the Clean Water Act (CWA); the EPA encourages states and municipalities to maximize their infrastructure-improvement dollars.

This plan surely did not exclude collections systems efficiency. But a collection system’s efficiency is not just about flow rates: it’s the combination of accurate flow data, pump capacities, head losses, and horsepower to produce usable results. Tuning the accuracy will provide key data for I & I studies, hydraulic modeling, and lift-station efficiencies. Beaudoin’s dedication and Maid Labs’ research has produced a product which takes the guesswork out of lift station performance and meets the current needs of utilities pursuing their CWA objectives. ■

REFERENCES

1. Salguero, Louis. (August, 12 2011). Wastewater Flow Measurement (SESD Publication No. SESSPROC-109-R3). Athens, GA: U.S. Environmental Protection Agency Science and Ecosystem Support Division. 1-16.

2. Stoner, Nancy and Cynthia Giles. (October 27, 2011). Memorandum: Achieving Water Quality through Integrated Municipal Stormwater and Wastewater Plans. United States Environmental Protection Agency. Washington, D.C: Government Printing Office.

_________________________________________________________________________

ABOUT THE AUTHOR

Gary L. Kerr is the national product manager for Maid Labs and brings with him over twenty years of experience in product performance and monitoring of wastewater pump station. For more information, visit www.maidlabs.com.

_________________________________________________________________________

MODERN PUMPING TODAY, October 2013

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!

![]()