In this article, the vibration signature on bearing housing caused by shaft rub was studied through applying a rotor rub device on a Machinery Fault Simulator (MFS)TM. Full annular rub was simulated with three types of rub head materials. These three rub materials are aluminum, brass, and plastic. The experiment was carried out under three speeds, i.e., 1,000; 2,000; and 3,000 RPMs. Acceleration signal on bearing housing were collected and analyzed. Several observations about the effect of rub on bearing housing vibration were presented.

INTRODUCTION

For rotating machinery, rub is an undesired contact between a rotating and stationary part. It causes direct damage to the contacting parts. The damage can range from mild, for light rub, to complete destruction of the machine.

Generally, rub is caused by some malfunction that produces a shaft/rotor and stator contact. Some examples of the malfunction which can cause rub include: excessive radial loads, looseness, misalignment, etc. The rub can be divided into partial radial rub and full annular rub. When the actual rub contact occurs over a fraction of the vibration cycle, it is called partial rub. When it occurs over the entire vibration cycle, maintaining continuous contact, it is called full annular rub.

How to identify the vibration signature caused by rub on bearing housing is very critical in preventing rub related machinery failure. Also, the effects of rub material and speed on vibration signature associated with rub are two other key issues. In this work, efforts are made to answer the above questions by simulating rub in a controlled way.

EXPERIMENT SETUP

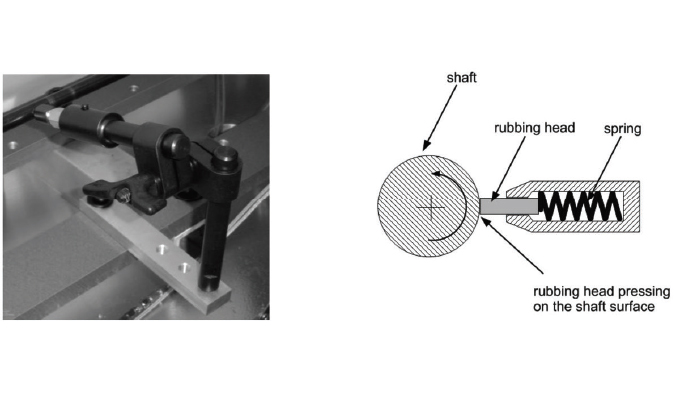

Shaft rub was simulated on a Machinery Fault Simulator (MFS) with a rub kit. The rub kit is illustrated in figure 1a. This kit permits the simulation and evaluation of typical rub phenomena associated with a variety of materials under different angle, loading, and lubricant conditions. The kit consists of an adjustable tool holder for the rub material, a vertical post, a horizontal bar, and clamping mechanism. A spring inside the tool holder is compressed and exerts a moderate pushing force which presses the rub head against the shaft or rotor surface (figure 1b). Therefore, the rub head will maintain continuous contact with the shaft all the time. The type of rub simulated with this rub kit is full annular rub.

The shaft in the MFS is 5/8 inches in diameter and made of steel. It is supported by two rolling element bearings. During the test, the shaft is not connected with any other components except the motor.

Three types of rub head materials were tested in this work. They are aluminum, brass, and plastic. The experiment was carried out under three speeds, i.e., 1,000; 2,000; and 3,000 RPMs.

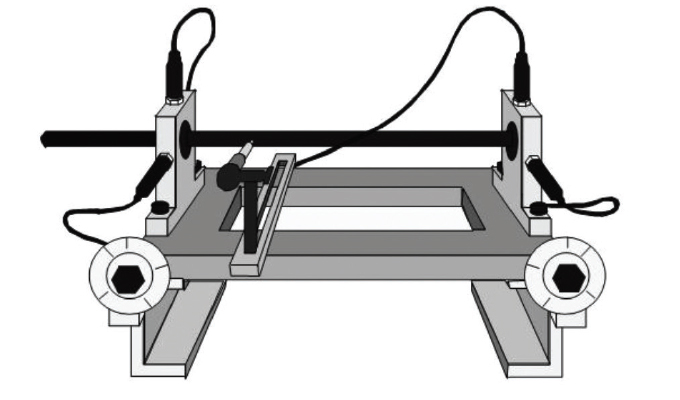

Two accelerometers were installed on each of the two bearing housings in horizontal and vertical directions respectively to collect the vibration data as illustrated in figure 2.

EXPERIMENTAL RESULTS

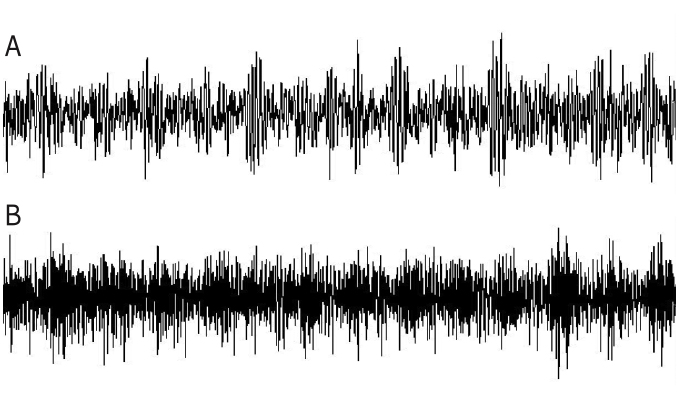

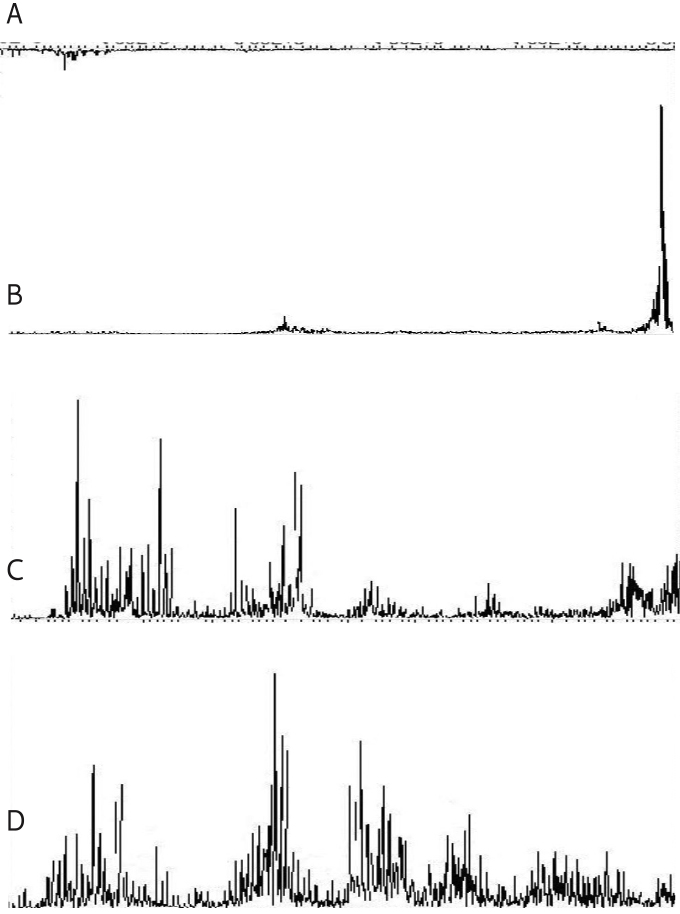

The vibration signal used for displaying and analyzing in this section is from the acceleration on the inboard bearing housing in the horizontal direction. Figures 3a and 3b display the baseline and shaft rub (aluminum rub head) vibration waveforms with the same time period at 1,000-RPM speed respectively. The amplitude range of figure 3a is 1.2e-2. The amplitude range of figure 3b is 2.4e-1. The vibration amplitude of bearing housing increases significantly with rotor rub for 1,000 RPMs.

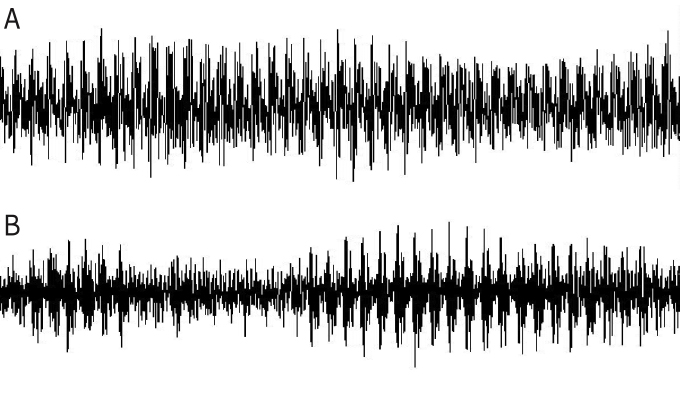

Figures 4a and 4b display the baseline and shaft rub (aluminum rub head) vibration waveforms with the same time period at 3,000-RPM speed respectively. The amplitude range of figure 4a is 1.1e-1. The amplitude range of figure 4b is 3.7e-1. The vibration of the baseline and rub one have the same amplitude level. Comparing figure 4 and figure 3, it can be noticed that the vibration amplitude of bearing housing of the baseline increases significantly with speed.

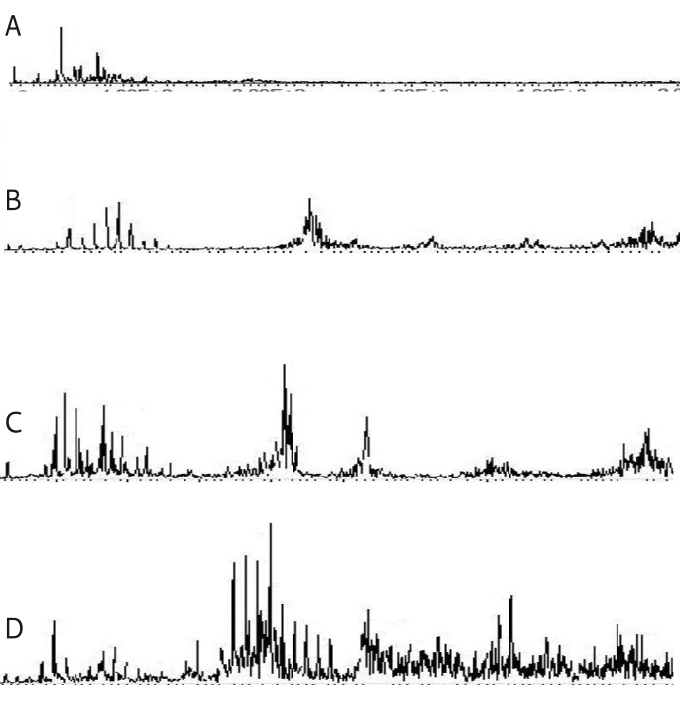

The vibration spectrum of bearing housing without rub and with rub (different rub head materials) for 1,000 RPM-speed are illustrated in figure 5. Figure 5a is the spectrum without rub. Figures 5b, 5c, and 5d are the spectrums for rub head materials of plastic, aluminum, and brass respectively. From figure 5, it can be noticed that the spectrum with rub has significant difference to that without rub. A careful inspection of figures 5c and 5d indicates that the spectrums for rub materials of aluminum and brass are similar to each other. The spectrum for the plastic rub material has a unique characteristic as illustrated in figure 5b. In figure 5b, there is a dominant resonance component close to 2KHz. Figures 5c and 5d suggest that the spectral components for the aluminum and brass rub materials are much more complicated than the case of plastic rub material. A lot of structural resonances are excited by the rubbing with these two materials. A comparison of figures 5b, 5c, and 5d indicates that there is a common resonance excited around 900Hz.

The vibration spectrum of bearing housing without rub and with rub (different rub head materials) for 2,000-RPM speed are illustrated in figure 6. Comparing figure 6 with figure 5, similar bearing housing vibration signatures can be observed. The plastic rub generates a dominant resonance component around 2KHz. The spectrums for the aluminum and brass rub materials are close to each other. And a common resonance around 900Hz emerges much more clearly in figures 6b, 6c, and 6d. However, the amplitude difference between baseline and rub cases decrease. In figure 5a, the baseline vibration is very low. However, the baseline vibration in figure 6s cannot be neglected.

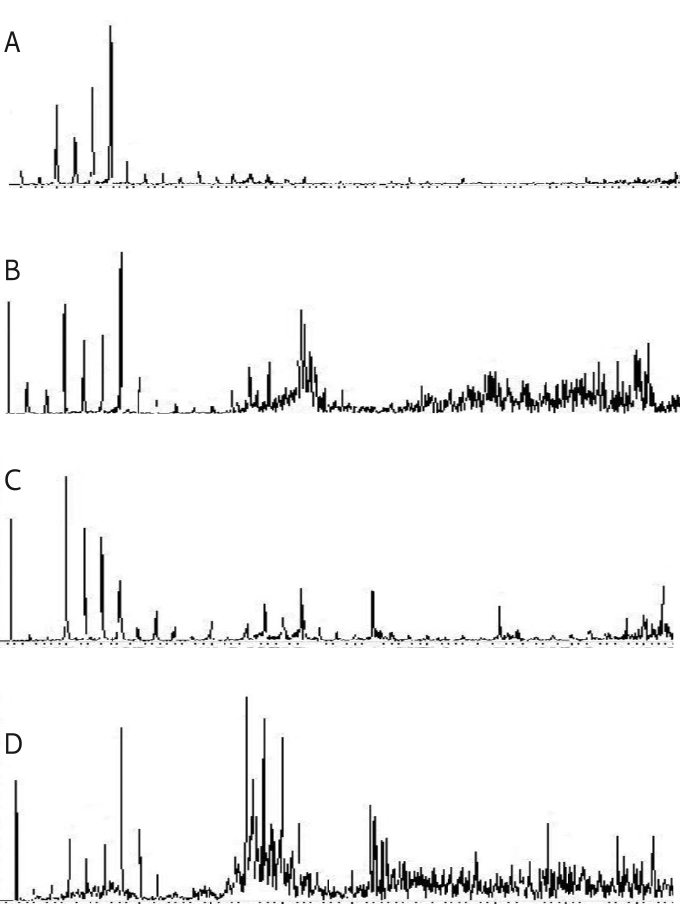

The vibration spectrum of bearing housing without rub and with rub (different rub head materials) for 3,000-RPM speed are illustrated in figure 7. Figure 7 indicates that with the continuous increase in speed, the baseline vibration has increased to the same level with the rub cases. The spectrums below 600Hz for the baseline and all the three rub cases are very similar. The difference between baseline and rub spectrum are in the high frequency range. The rub excites high frequency structure resonance which is illustrated clearly by the frequency components above 600Hz in figures 7b, 7c, and 7d. Comparing figure 7 with figures 5 and 6, the spectrums for the plastic and aluminum rub have the largest changes. Interestingly, it seems their spectrums switch characteristics between figure 7 with figures 5 and 6, i.e., figure 7b is similar to figures 5c and 6c and figure 7c is similar to figures 5b and 5b.

SUMMARY AND OBSERVATIONS

In this study, the vibration signature of rotor rubbing was studied by applying a rotor rub device on a Machinery Fault Simulator. Full annular rub was simulated with three types of rubbing head materials. The three rub materials are aluminum, brass, and plastic. The experiment was carried out at three speeds, i.e., 1,000; 2,000; and 3,000 RPMs. Acceleration signal on bearing housing were collected and analyzed.

From this experiment, it can be observed that rub generates high frequency structure resonances. Although the profile of the vibration spectrum caused by rub with a certain material will change with the speed, the excited structure resonance positions do not change. Under a certain speed, a specific structure resonance might be more dominant in the vibration spectrum caused by one rub material than those caused by other materials.

FOR MORE INFORMATION

SpectraQuest, Inc. is a leading developer and manufacturer of complete turn-key systems for training and diagnosis in machine vibration analysis, rotor balancing, and shaft/coupling alignment. System includes machinery fault simulators, interactive training program, data acquisition hardware/software, and accessories. To accelerate the learning and design process SpectraQuest offers a series of interactive software CDs on vibration fundamentals and calculations, signal processing, alignment, and balancing. For more information, visit www.spectraquest.com.

MODERN PUMPING TODAY, April 2022

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!