There may be instances when a building water system needs to be shut down or placed in an isolation condition, including temporary closures of the building, building renovations, or isolation of a section of a larger distribution system. A water system that is in a low flow condition is slightly different but presents a similar potential for the development of biofilm and the amplification of potentially harmful bacteria.

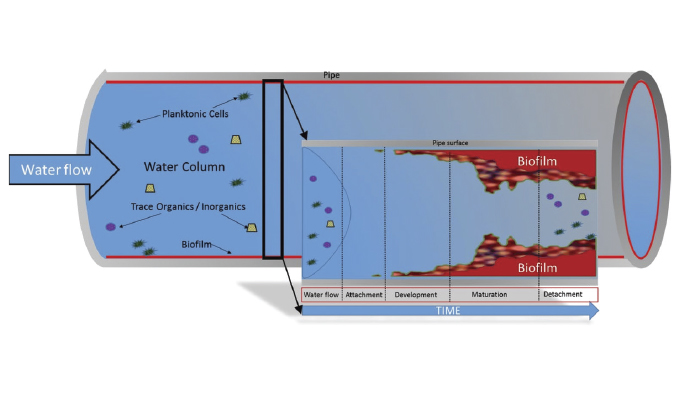

Under normal building operation, chlorinated or chloraminated water is supplied to a building from the local municipality and the disinfectant is evenly distributed throughout the building water distribution system. However, loss of disinfectant residuals may occur due to a number of factors, including disinfectant demand, temperature, nutrient loading, and water flow. In situations described above, if the water flow stops or is significantly reduced, bacterial growth and biofilm development can increase rapidly as the disinfectant in the water is depleted.

In cases where a building’s water flow has been reduced (but not valved off) it is important to develop a protocol or management plan for consistently flushing as many of the distal (away from the main header) faucets, fixtures, and outlets as possible. Each of the water lines off the supply main has the potential for concentrating bacteria and biofilm. Flushing these lines will help exchange the stagnated water with fresh water containing a disinfectant.

For building water systems that have been completely isolated for an extended period, a potable water disinfection (using chlorine) will be the process for any new or older piping. This will be part of the commissioning protocol and is typically mandated by the local health department prior to occupancy or human consumption. In this condition a total coliform test (positive/negative) is performed and must be tested within twenty-four hours of sampling. Check with the local health department for specific guidelines.

STEPS TO BE CONSIDERED

The following are some simple actions that should be considered while a building is under low-flow conditions:

- Flow and exchange 3 to 7 percent of the water based on estimated total water volume for the building.

- Flow water at each distal outlet until there is a chlorine residual (free or total) based on the type of disinfectant. This will require a free or total chlorine test kit. Additionally, a specific test for monochloramine can be used for chloraminated systems.

- For hot water potable systems, flush the water to the point where either the water temperature is the same as the hot water main or above 120 degrees Fahrenheit, or 49 degrees Celsius, (where allowed). This will require a thermometer.

Once the building water system is scheduled to return to normal service, flushing should be increased, and additional testing is advised.

- Disinfectant levels should be at or near the supplied water levels at all locations in the building.

- Samples for total heterotrophic plate count should be collected and cultured. Total heterotrophic plate counts should be less than 500 colony forming units.

- Local certified water testing laboratories will be able to perform these cultures and the interpretation of the results.

One of the most effective means of reducing bacteria amplification and biofilm development is simply exchanging the old water with new. Waterborne pathogens can concentrate in stagnant water if the building distribution system is not flushing regularly. It is important to develop and follow a written plan for both low flow and idle water systems. Documenting the process and procedures followed will help if a shutdown is required in the future.

Further details, including proactive steps to minimize water stagnation during building closures and actions items to address water quality prior to reopening, can be collected from a recently published document from the United States Environmental Protection Agency on restoring water quality in buildings.

RESTORING YOUR WATER QUALITY, THE RIGHT WAY

Per the EPA guidelines, facility owners are advised to contact their water utility about local water quality and to coordinate maintenance activities prior to flushing the building. Additionally, check information from the local public health department for any local requirements for reopening and follow appropriate regulations and policies for worker safety and health.

Once the facility is ready to begin the flushing process, the EPA advises owners review how water moves through their building, from the street to each point of use—this includes inspecting the plumbing, maintaining any water treatment systems (e.g., filters, water-softeners) following manufacturer’s instructions, and ensuring the hot water system is operating as specified.

The process for the flush itself should follow a straightforward procedure: First, flush the service line that runs from the water main to the building. Next, flush the cold water lines. With that step completed, it is time to drain and clean water storage facilities and hot water heaters. Now, flush the hot water lines. Finally, flush, clean, and maintain devices connected to the plumbing system following manufacturer’s instructions.

FOR MORE INFORMATION

As part of the Kurita Group, a leading industrial water solutions provider in the world, Kurita America brings innovations to market through a unique, customized water management approach called the Kurita Way. The Kurita Way embodies complete water harmonization through a consultive engineering engagement. By incorporating all aspects of our customers’ facility, including chemical, mechanical, and operational components, Kurita America gets to the root cause of customers’ most complex challenges to deliver optimal results and overall lower cost of ownership for a better, more sustainable world. For more information, visit www.kuritaamerica.com.

MODERN PUMPING TODAY, January 2023

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!