Wey knife gate valves have been used in the municipal sewage treatment market for nearly fifty years. The valve incorporates unique design features that overcome typical problems found in other knife gate valve designs. Today, the Wey knife gate valve has spread throughout the industry in all of Central Europe and other parts of the world where the original valve installations continue to perform successfully.

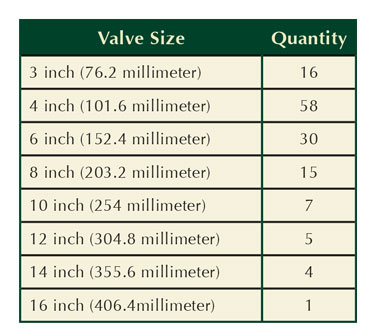

Table 1: Size and quantity of valves used in sewage treatment plant expansion.

ENERGY SAVINGS AS A RESULT OF GREATER VALVE FLOW CAPACITY (Cv)

This following case study is based on an actual sewage treatment plant expansion where the valves were supplied by Wey Valve, Inc. (see Table 1) and presents these four premises:

- Increased valve flow capacity (Cv) will result in improved overall plant efficiency due to reduced pumping motor power consumption.

- Reduced valve envelope sizes results in smaller building sizes.

- Reduced valve size and weight results in reduced foundation and pipe support sizes.

- Reduced valve face-to-face dimensions results in less piping.

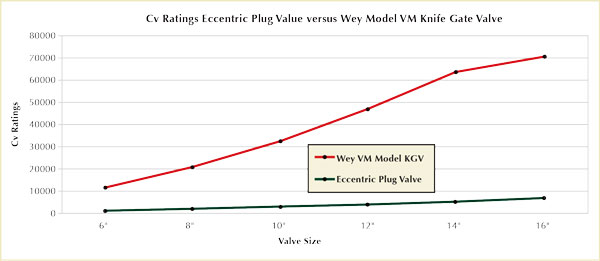

The basis for the cost comparison was a listing of flow capacities (Cv) for a popular eccentric plug valve (70 to 80 percent area) vs the Wey model VM knife gate valve.

The headloss (H) in feet through a valve is determined by: H = (Q/Cv)2 X 2.31 where Q is in gallons per minute and the power consumed (P) in horsepower, is determined by

P = QH / [3960(e)]

where (e) is the overall pump/motor efficiency.

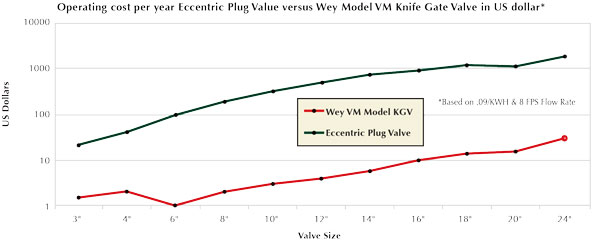

The estimated annual power cost will be based on 75 percent use, 8 fps, 70 percent overall pump/motor system efficiency and $0.09/KWH power cost. The estimated annual power cost for each valve under the assumed conditions is as follows:

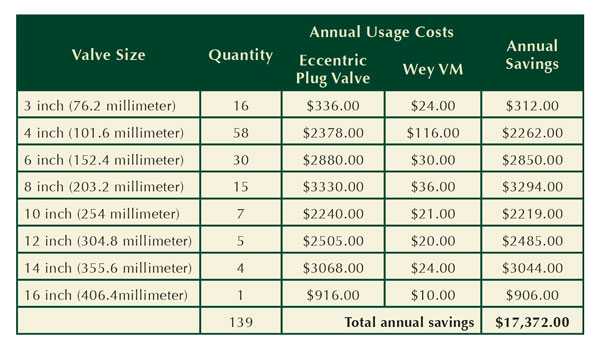

By taking the annual cost savings per valve size times the number of valves used on the project the total annual cost savings when using Wey knife gate valves on this project will yield a $17,372 year one cost savings or a cost savings of $434,300 over a twenty-five year life of the project.

It is noteworthy that despite the fact that the Wey model VM valve has a substantially larger flow capacity than the commonly used eccentric plug valve, the average selling price of the Wey valve is less than the eccentric plug valve. Eccentric plug valves are also available with 100% bore areas (higher Cv’s) but with a substantial price premium that more than offsets any savings in energy costs.

Further cost advantages associated with the use of the model VM valve include reductions in building space, size and cost of footings and foundations, piping, and size and numbers of pipe hangers. Also, use of the model VM valve could make it possible to use potentially smaller valve sizes and reduced pump and motor sizes. Furthermore, the Wey model VM knife gate valve fully complies with the AWWA C520-10.

RETHINKING KNIFE GATE VALVES

Knife gate valves in general have had a bad reputation in the municipal wastewater treatment market. Major problems that users have found include leakage to the exterior of the valve past the top gland as well as leakage past the seat of the valve. Knife gate valves have also been known for solids jamming in the seat and chest areas of the valve and requiring high input torque to actuate the valve, with unreliable actuation after prolonged periods of non-use. However, Wey Valve offers time-tested proven solutions to these common problems.

Top Transverse Seal

Wey knife gate valves do not make use of stuffing box and packing gland top seal designs. Instead, a unique top “transverse” seal prevents leakage to the exterior. If leakage does eventually occur, the valve can be repacked while in service and under full pressure.

Positive Seat Seal

The seat in Wey knife gate valves is a combination of metal and elastomer. The elastomer is mechanically retained to prevent “pull-out”. The gate is guided and supported for the full length of the stroke which when combined with the seat seal provides bi-directional bubble-tight shut-off from -28″ Hg vacuum to full pressure rating.

Self-Cleaning Design

Wey knife gate valves have a unique gate geometry and body bore contours to prevent solids from clogging in the valve. There is little space for solids to build up and in the event some small amount of solids is present, it is flushed out during actuation.

Reduced Operating Force

The unique gate geometry again plays a role in reducing operating force along with a molecular graphed polymer infusion on the stem reduces operating friction. Manually actuated valves utilize a non-rising “jack screw” mechanism to open and close the valves resulting in saved envelope space.

Long Life Reliability

An important measure of reliability in the wastewater treatment industry is how long a valve can remain “dormant” and then operate dependably after many years of inactivity. Wey Valves have a proven reputation for reliable operation after many years without operation. Experienced engineers often specify Wey knife gate valves for this reason alone. ■

About The Author

Wey Valve Inc. was founded in Nettleton, Mississippi as the North American sales and manufacturing headquarters for the Wey brand valve line. Since then, Wey Valve Inc. has developed various specialized models of knife gate and shear gate valves to solve specific process problems.

MODERN PUMPING TODAY, February 2015

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!