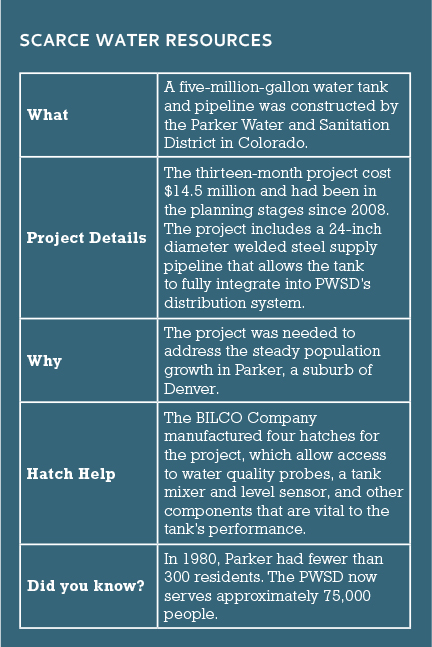

A new five-million-gallon tank and pipeline is bringing smiles to Parker Water and Sanitation District (PWSD) customers in a fast-growing Denver suburb. PWSD completed a thirteen-month, $14.5 million project that had been in the planning stages since 2008. Other projects and funding took precedence, but with recent growth in the Canyons, the new tank became a priority.

“We need to meet our expanding service area and continuing water demand,’’ says Project Engineer Alex Sofranko. “It will provide additional storage capacity for the drinking water and will then go to our wellhouses and get pumped out to the tank and then into distribution.”

The town of Parker has grown significantly over the past forty years. Slightly more than 20 miles southeast of Denver, Parker’s population has soared from less than 300 residents in 1980 to nearly 63,000. The Parker Water and Sanitation District was established in 1962 and serves approximately 75,000 people.

“The service area and the continuing water demand in Parker keeps growing,’’ Sofranko says. “We needed additional capacity for our drinking water and this project became a priority.”

SCARCE WATER RESOURCES

Like many other communities in Colorado, Parker faces water scarcity challenges due to reliance on diminishing groundwater supplies and projected population growth. Parker and other communities in Douglas County rely heavily on groundwater from aquifers.

Those aquifers, however, are facing depletion and are not replenishing at the same rate as they are being used. Some aquifers have lost as much as 6 feet in depth, and continued population growth is further straining existing water resources.

To help plan for the future, PWSD launched the Platte Valley Water Partnership alongside agricultural partners in northeast Colorado. The project will help diversify its water portfolio so that its customers are less reliant on Denver Basin groundwater. Instead, it will rely on renewable water sources for 75 percent of its water needs.

PROJECT DETAILS

PWSD’s Canyons Water Tank and Pipeline is a critical piece toward improving the agency’s infrastructure and planning for future growth. Working with design engineering consultants, Providence Infrastructure Consultants (PIC), the focal point of the project was a 200-foot diameter, five-million-gallon potable water storage tank and a 24-inch diameter welded steel supply pipeline that allows the tank to fully integrate into PWSD’s distribution system. A nearby interconnect metering station was also incorporated into the system to facilitate water transfer between PWSD and neighboring Castle Rock Water.

The project’s primary challenge was constructing the tank at the same elevation as an existing water storage tank in the district, located 10 miles to the east, to ensure proper functionality. PIC used triangulated satellite data to ensure accurate and matching elevations.

“Furthermore, excavation had to be made through 25 feet of rock at the selected site which resulted in additional hurdles during construction including developing noise mitigation measures to limit impacts to nearby residences,’’ PIC explains. “In addition to addressing difficult subsurface conditions, the tank’s overflow and drain facilities required detailed planning and unique design to minimize visual and operational impacts to adjacent properties.”

“We ended up hitting a lot more bedrock than we anticipated as they were excavating for the tank,’’ Sofranko says. “That kind of drew the timeline out a little bit. They ended up having to crush a lot of that rock and haul it out with a truck, and that was a bigger expense than we anticipated.”

Lastly, design coordination between PWSD and Castle Rock Water related to the future operational needs and requirements of the interconnect metering station highlighted the project’s overall complexity, necessitating significant stakeholder collaboration.

The project also included design coordination between PWSD and Castle Rock Water to address future operational needs and requirements of the interconnect metering station.

PIC said the tank’s overflow and drain were designed as a single facility to reduce the project’s cost. PWSD and PIC also collaborated with a hydraulic modeling consultant to optimize sizing and ensure long-term system functionality for accurate water transfer, remote operations and flexible operation and performance.

EQUIPMENT ACCESS

Among the important components for the project are four access hatches from BILCO, a manufacturer of specialty access products. The project includes one hatch that is 7 feet by 12 feet and three that are 5 feet by 9 feet.

The hatches allow access to water quality probes, a tank mixer, and level sensors, among other components, which are vital to the performance of the tank. Tank mixers, for instance, circulate water inside the tank to achieve water quality and consistent water temperature. By lowering the overall water temperature, mixing helps lower the tank headspace temperature and reduces corrosion rates. Mixers can also blend variations in water quality going into water tanks to deliver consistent, stable water quality.

“We have tank mixers that are able to keep five million gallons of water mixing, so we needed large hatches for installation,’’ Sofranko says. “Our contractor for this project selected the doors and they met the specifications for the project. We’ve used BILCO products in other projects and we’ve found them reliable.”

The hatches include compression spring operators for one-hand operation and automatic hold-open arms that lock the covers in the open position to ensure safe egress. They also are constructed with corrosion-resistant materials, an important consideration for projects that center on water management.

A BILCO KD door, which is used for applications where water or liquid infiltration is not a concern, was also included in the project. The 3-foot, 6-inch by 8-foot KD door also allows access to equipment.

BILCO’s manufacturer’s representative, Dalco Industries, provided the hatches for the subcontractor, Garney.

MANAGING GROWTH

The town of Parker’s Master Plan addresses the community’s concern with its rapidly expanding population. The area started as a small trading post in 1864, a place where traders and Indigenous Peoples met to exchange goods. The town was surrounded by vast open spaces and served the agricultural community.

The area has since transitioned from its agricultural roots, with farms giving way to housing developments and shopping centers. Between 2000 and 2010, Parker’s growth rate reached 92 percent and was one of the fastest-growing towns in the state and among the fastest-growing in the nation.

Amid the rising population, Parker is wrestling to deliver the infrastructure its residents need while managing responsible growth.

“Our goal,’’ according to the Town’s 2035 Master Plan, “is to maintain the hometown feel that is important to our citizens.”

Thomas Renner writes on building, construction and other trade industry topics for publications throughout the United States. The BILCO Company has served the building industry since 1926. During these years it has built a reputation among architects, engineers, specifiers, and the construction trades for dependability and for products that are unequaled in design and workmanship. For more information, visit www.bilco.com.