With the viability of steel industry seriously impacted by high energy costs, RMI Pressure Systems will be showcasing its energy-efficient high-pressure reciprocating pump solutions at the Association for Iron and Steel Technology (AISTech) conference, the steel industry’s largest annual trade show and exposition, this month. Below, RMI Pressure Systems’ Global Sales Manager Sean Heary breaks down what to expect.

MPT: As you were preparing for AISTech, what concerns do you see rising to the top for the steel industry as a whole?

Sean Heary: Among the key issues on AISTech delegates’ minds will be the dramatic increases in energy costs, as well as inflation, and rising capital costs. Other challenges facing the industry include the disrupted supply chain resulting from Covid-19 economic lockdowns, followed by the Russia-Ukraine war. The sector is looking for lower capital and operating costs, which is what RMI Pressure Systems can deliver through our years of experience with best-in-class plunger pumps.

MPT: What are you hoping to share with customers at AISTech?

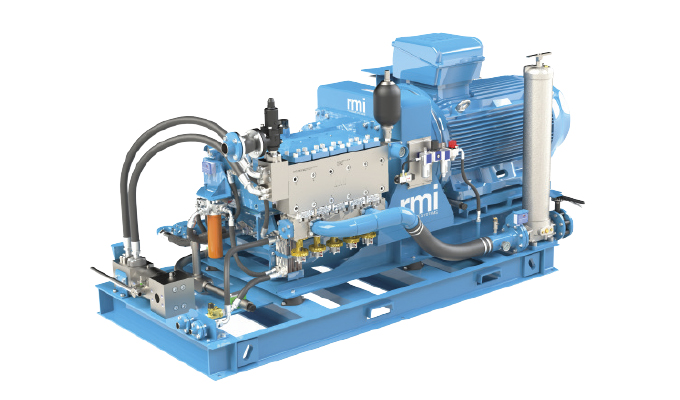

Sean Heary: At our exhibition booth at AISTech, the company will be sharing insights with visitors on our hydraulic power packs and systems for heavy industry—for applications including descaling, forging, and extrusion. We will also be promoting solutions for high-pressure flow applications such as cleaning, cooling, and dust suppression.

With its global installed base, RMI Pressure Systems has local service infrastructure in key markets to support customers. Our company’s manufacturing hub in Manchester, England, includes an in-house research and development capability to drive continuous innovation of its products and solutions. It has operations in the United Kingdom, Europe, the United States, China, India, and Australia.

MPT: Are there any products you’ll be placing emphasis on at the show?

Sean Heary: The two models in the RMI Pressure Systems’ S Series range—the TRIMAX three-plunger pumps and the QUINMAX five-plunger pumps—have proven volumetric efficiencies up to 98 percent. Their fluid end components are designed with computational fluid dynamics (CFD) to maximise efficiency.

Our pumps feature a quality and robust design that facilitates extended operating life, optimal uptime, productivity, and low total cost of ownership. RMI reciprocating pumps deliver 95 percent energy efficiency; variable speed technology reduces pressure when it is not required, so there is less wear and tear on system components—for longer life.

MODERN PUMPING TODAY, May 2023

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!