Thordon Bearings recently provided water-lubricated elastomeric polymer bearings for installation to cooling water pumps commissioned for a major power plant expansion project by the state-owned Taiwan Power Company. Eiger Engineering, Thordon’s authorized distributor in Taiwan, delivered Thordon SXL and Composite bearings for the cooling water pumps. Below, Sam Williams, Thordon’s regional manager, APAC, and Ronnie Chen, director at Eiger Engineering, discuss this project and what it means for the region.

MPT: How did Thordon and Taiwan Power Company come together for this project?

Sam Williams: Thordon’s SXL and Composite non-metallic bearings were specified by San Tai Pumps, which is providing cooling water pumps to Taiwan Power Company, which is significantly expanding its generating capacity at the Hsin Ta power plant in Kaohsiung and the Taichung power plant in Longjing, Taichung.

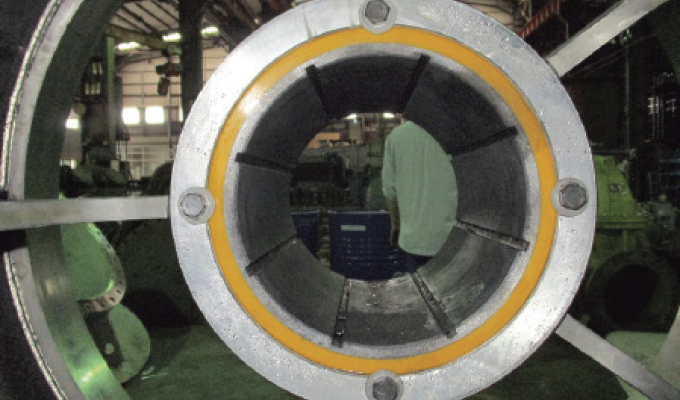

At Hsin Ta, the power plant is currently being expanded from three turbines to a six-turbine operation. Each of the three new turbines requires three cooling water pumps, which will extract seawater adjacent to the power plant for cooling. Seawater will also be used for lubricating the Thordon bearings. Each pump shaft is more than 32.8 feet in length and for each pump, six Thordon bearings are required—adding up to a total of fifty-four bearings for the Hsin Ta project.

MPT: What made Thordon the right fit for this application?

Ronnie Chen: The Thordon Composite material is ideal for more aggressive environments and therefore for use at the bottom of the pumps where they are extracting the water from the seabed—the Composite material is very resistant to abrasive media such as sand and other particles. The SXL bearings are used higher up the pump shaft; this material is ideal here because of its dry start up capability and long wear life.

Sam Williams: The long lifetime of the Thordon pump bearings, with less wear shown during overhauls, is a clear advantage. Typically, the bearings do not require replacement even at the two-year interval overhaul. Once the bearing used on the cooling water pumps’ original design has been monitored in action and shown to be running smoothly, the end user is expected to specify Thordon bearings for future projects.

MPT: How has this partnership worked so far?

Sam Williams: The first cooling water pump was installed at Hsin Ta power plant in mid-April 2023 and delivery of the project is due for completion in 2024. The first pump for the Taichung power plant expansion is in production, and delivery to Taiwan Power Company for this project is expected in the first quarter of 2024. In total, San Tai will deliver fifteen cooling water pumps to Taiwan Power Company over three years, all of which will feature Thordon bearing solutions.

Ronnie Chen: Eiger Engineering worked closely with San Tai Pumps on the TPC project, to select the suitable bearing material, analyze water flow, make calculations, issue drawings for approval by Taiwan Power Company, and provide support—collaborating in the best interests of all stakeholders.

MPT: How does this project fit within Thordon’s overall plans in the region?

Ronnie Chen: San Tai Pumps has specified Thordon Bearings in its pumps for the past twenty years, mostly for application in power plants. This has been based on factors including reliability, low maintenance costs, and the clear environmental benefits of using seawater for lubrication. The manufacturer wants to have high-quality components, so it has chosen the Thordon brand.

As Taiwan Power Company has embarked on its major power plant expansion program, Eiger Engineering and Thordon Bearings have the opportunity to supply on an even larger scale. San Tai Pumps is also working on a bid to supply cooling water pumps for further power plant expansions.

MODERN PUMPING TODAY, August 2023

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!