Located just south of the England’s second largest city of Birmingham, the small town of Redditch is not without its own municipal concerns—especially when it concerns improving the reliability and efficiency of their local wastewater system. One key concern was upgrading the suction lift application, but officials also desired to maintain some of the existing infrastructure. They found their solution in Hidrostal’s self-priming filter backwash end suction pumps.

LOOKING FOR AN ANSWER

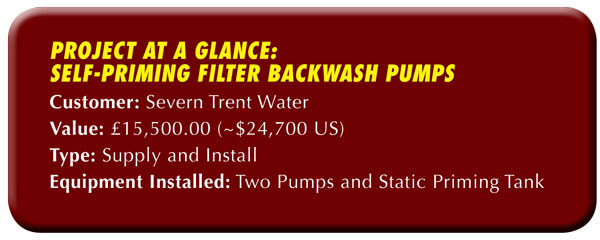

In the summer of 2012 Hidrostal supplied and installed a static priming tank system to feed two new 11 kilowatt Hidrostal end suction pumps. The new system was required to replace existing but unreliable self-priming pumps installed on a suction lift application at Redditch wastewater treatment facility. The application was to feed the sand filter backwash process.

A PERFECT FIT

Hidrostal were selected because the solution proposed utilized a lot of the existing equipment such as pump house, pipework, plinths, and control panel. This simple but clever solution represented a good value engineered and upgraded solution with a good low risk CDM compliance.

The static priming tank system is built around the Hidrostal Screw Centrifugal Pump, renowned for its high efficiency and low NPSH capabilities, an optimum centrifugal pump for suction lift applications. In fact the improved efficiency meant the new Hidrostal pumps were able to reduce the installed kilowatt size. One 11 kilowatt Hidrostal pump was capable of pumping more than two of the originally installed 18.5 kilowatt self-priming pumps.

Due to the higher efficiency of the Hidrostal system duty/standby was now possible, compared to the original duty/assist/standby layout. The static priming tank was installed into the position of the original middle assist pump, even making use of its concrete plinth.

On this installation Hidrostal supplied and installed two identical end suction bearing frame pumps of model E06U-MMN3R+EFM1X-M160 fitted with 11 kilowatt, 4-pole, WEG, WIMES High Efficiency motors. The two pumps were installed alongside a suitable sized and fabricated static priming tank to generate a suction lift of 7.5 feet (2.3 meters).

IMPROVED PERFORMANCE AND SAFETY

The installation now only required a single suction pipe from the wet well to the static priming tank. This in turn provided a new suction connection to the new pumps. Two of the original suction lines were removed from the pump station layout, improving access. The discharge pipework was maintained apart from the pipework in the redundant pump position. This was removed and blanked off, again improving access.

The Hidrostal above ground solution was compared to a number of submersible wet well proposals. The above ground solution was selected because it negated the risks of entering and lifting around the wet well, for both the installation and on-going maintenance requirements associated with submersible pumps.

New Hidrostal installation

LONG-TERM SOLUTIONS

Since commissioning in June 2012, the customer is very satisfied with the solution and system performance. Also, a follow up in April 2013 and later in October 2013 saw John Ratheram, service delivery manager for Redditch area report that the installed pumps continued to meet their needs and were operating successfully without incident.

Finally the long standing self-priming issue had been solved at this part of the works. The original 13.2 gallons (50 liters) per second pump duty, delivered from a pair of unreliable duty/assist self-priming pumps, is now being handled by a single and reliable Hidrostal duty pump with an output of 15.3 gallons (58 liters) per second. The Hidrostal solution was the simplest, safest, and most reliable solution proposed for the Redditch problem. ■

About the Author

Andy Wilson is the business development manager at Hidrostal Ltd. With over thirty years of experience and having deployed thousands of pumping systems, Hidrostal fully understands the needs and technical requirements of today’s pump users. For more information, email sales@hidrostal.co.uk or visit www.hidrostal.co.uk.

MODERN PUMPING TODAY, October 2014

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!