Lobe pumps have been a staple in materials transport for more than 100 years, but they have one major design flaw: Pulsating flow. OCOR Corporation has released the prototype of a fully reversible lobe pump that produces both high pressure and high volume flow in a single stage, delivering continuous, non-pulsating flow.

MULTIPLE SEGMENT LOBE PUMP

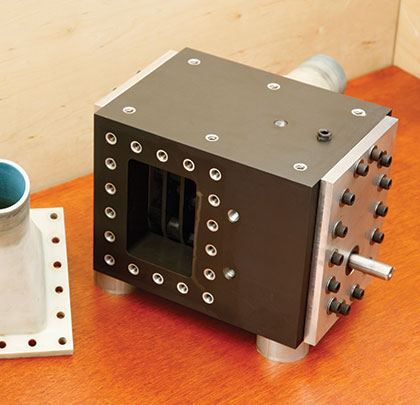

The OCOR Multiple Segment Lobe Pump (patent pending) transports all types of media, including high and low viscosity liquids, air and gases, as well as semi-solids such as mud or slurries of combined materials in a smooth, continuous stream. After years of proof-of-concept testing, this new design has the potential to redefine lobe pumps in commercial applications worldwide and is now ready for a development partner.

The flow variations that come from traditional lobe style pumps have been eliminated through OCOR’s patented multi-segment rotor system where side-by-side nesting rotors (a segment) divides the incoming flow sequentially into arc segments that, when rotated, positively displace (pump) the media through the isolated region (between inlet and discharge) within the containment housing.

BREAKTHROUGH TECHNOLOGY

As an example, picture three individual rotor segments separated by stationary seal plates on a shaft, each of which have three lobes which can be either flat sided or helical in shape, then each pumping chamber, (i.e. the volume encased by adjacent lobes and the stationary containment housing), would contain one eighteenth of the media volume that is seamlessly transported from inlet to discharge in one revolution of the input drive shaft (see figure 1).

The result of the new design, unlike any others on the market, is that the pump can run at any desired speed, in either direction, with constant displacement efficiency and deliver both high volume and high pressure.

COUNTLESS APPLICATIONS

In development for more than six years, the new lobe pump technology has countless applications. Solving this major design issue, when it comes to materials delivery, can be an invaluable breakthrough to industries worldwide.

A sampling of some of the potential markets to use the new OCOR Multiple Segment Lobe Pump include:

- Water Treatment/Waste Management: The pump can handle semi-solids, raw sewage and high particulate waste water flow with minimal inlet filtration. Liquids can be transferred to various stages of the purification process with a single pump that can flow in either direction. Since the pump is fully reversible, it greatly simplifies delivery and return of material.

- Desalinization: Current desalinization process design requires a variety of pump applications, the most demanding of which is high volume, high pressure water flow to the reverse osmosis membrane cartridges. The OCOR Multiple Segment Lobe Pump can deliver high volume, pressure and high efficiency for the application in a single stage. The OCOR pump eliminates the need for a reverse flow pump by simply reversing the rotor rotation. Additionally, there are currently dozens of additional pumps required to operate the entire desalinization process. The OCOR Multiple-Segment lobe pump can replace all of the pumps with one or two different size pumps that can operate a various speed thereby saving maintenance and replacement inventory.

- Marine Propulsion: The OCOR Multiple-segment lobe pump is ideal for use as a submerged water jet propulsion device when coupled with an advanced variable area discharge. Analysis of the propulsion system, when compared to a conventional propeller driven watercraft, indicates a possible fuel saving of approximately 40 percent over the full range of engine RPM and vessel speed.

- Firefighting: The high inlet suction (NPSH) characteristic of the pump makes it ideal for firefighting from a fresh or salt water vessel. Longer, high volume flow trajectories as a result of the positive displacement pump are possible.

- Oil and Gas Pipeline Operations: Flow through the OCOR Multiple-segment Lobe Pump is near linear, making it ideal for efficient pressure boost in water and oil pipelines.

- Air and Gas Compression: The new positive displacement design insures that none of the rotating pump segments can touch any of the stationary surfaces within the containment housing thereby eliminating any chance of contamination caused to surface contact wear. The result means no need for internal lubrication of any kind, just pure gas flow. Also, the effects of adiabatic heating resulting from the compression process are significantly reduced with this new design compared to piston type compressors.

TESTING DETAILS

A fully functional prototype was designed, fabricated and tested in order to verify the viability of the sequential rotor concept. For simplicity, the test unit was fitted with straight lobe rotors rather than helical lobe rotors, however, the segmented rotor geometry applies to both rotor styles. Over a series of controlled tests, at shaft speeds from 300 to 1120 revolutions per minute, the pump demonstrated over 81 percent displacement efficiency in the transport of both liquid and gas material. A demonstration of the prototype unit can be viewed OCOR’s YouTube channel.

ABOUT THE AUTHOR

Maki Onari is manager of turbomachinery testing and Juan Gamarra is senior staff engineer at Mechanical Solutions, Inc. (MSI). MSI performs consulting and R&D, as well as provides design, analysis and testing services for organizations throughout the US and overseas. MSI is proud of its outstanding track record in solving some of the world’s most difficult technical problems. For more information, call 518.320.8552 or visit www.mechsol.com.

____________________________________________

MODERN PUMPING TODAY, July 2015

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!