Water is required throughout a food and beverage facility for various uses, including makeup water for cooling towers and boilers, washing of equipment and input for the production of goods. That water can be delivered through a supply connection from a municipal system, extracted from the local environment’s natural water supply, such as a ground well, or by reclaiming existing wastewater from the facility’s processes with advanced reuse treatment, lowering the plant’s fresh water requirements.

Since water is an essential element in food or beverage operations, reusing it can reduce a business’s water usage ratios, help meet sustainability goals, lower supply risk, and contribute to cost savings, making it a top priority for many companies today.

THE BENEFITS OF REUSING WASTEWATER

Water is a resource that has been taken for granted for decades but is now a critical focal point for many companies, communities and governments as the earth faces a water crisis.

Only 2.5 percent of the world’s water is fresh water, and of that, only 1 percent is accessible as much is trapped in glaciers and snowfields (see reference 1). As a result, only a tiny fraction of the planet’s water is available for everyday use. By one estimate, global fresh water demand will exceed supply by a staggering 40 percent in 2030 if current trends continue (see reference 2).

As corporate citizens, businesses must look at their impact on the environment and assess how their operations affect the communities they operate in and serve. By reducing their source water requirements, food and beverage companies of any size can do their part to reduce environmental impact, while reinforcing their corporate social responsibility. Many companies also realize substantial cost savings from water-related investments.

Other benefits of water reuse include

- Enhancing sustainability practices

- Ensuring the appropriate water quality standards for food and beverage processes

- Mitigating business risk by lessening dependency on external water sources

These reasons help explain why water reuse is growing around the world. From this white paper, business leaders will gain an understanding of the deployment of water reuse technologies, including which elements should be considered when investing in a system.

WASTEWATER EFFLUENT

Wastewater that is discharged into a collection network is generally handled by a Publically Owned Treatment Works (POTW) or treated under the National Pollutant Discharge Elimination System (NPDES).

Publically Owned Treatment Works (POTW)

In the U.S., POTW facilities are typically owned by local governments or municipalities, and are designed to treat domestic sewage, not industrial wastewater. Some industrial facilities can be permitted to discharge water to these treatment plants if they follow certain pretreatment processes, such as removal of solids, reduction of biochemical oxygen demand (BOD) and adjustment of pH.

POTWs are sensitive to industrial discharge because of the potential impact it can have on their facility’s operations. As a result, many require corporations to pull permits for discharge and charge significant fees. In addition, fines and other penalties can be imposed for discharge permit violations.

National Pollutant Discharge Elimination System (NPDES)

Discharging water into a river, lake, creek or other body of water falls under the NPDES, a division of the Environmental Protection Agency (EPA). Companies wishing to discharge wastewater through the NPDES need to treat the water more heavily than if they were to discharge to a POTW facility.

As a government-regulated system, there are strict permit requirements for this type of discharge. In fact, many of these standards are more stringent than those imposed for reuse. Violations of these discharge requirements can result in the EPA issuing punitive fines and consent decrees, which subject plants to routine inspections to ensure compliance to standards. By not following the mandated provisions, companies can also find themselves responsible for environmental damage remediation.

Companies that are discharging wastewater either through POTW or NPDES should consider their full cost of wastewater disposal when evaluating treatment and reuse of wastewater.

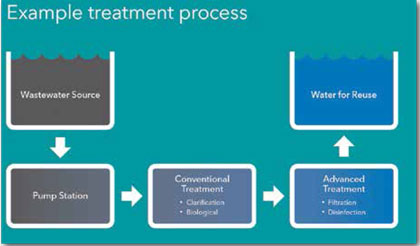

IDENTIFYING THE RIGHT TREATMENT OPTION

There are a wide variety of technologies commercially available for wastewater treatment in reuse applications. Those technologies can be classified as conventional treatment processes, which can remove solids, and adjust pH and chlorine levels, or advanced processes, which filter and oxidize water resulting in a higher quality product. Advanced methods give the plant more flexibility with how and where the recycled water is used.

CONVENTIONAL TREATMENT PROCESS

A conventional treatment process removes solid waste found in water. The technologies in this category provide minimal disinfection and include the use of screens, dissolved air flotation and primary clarifiers, filters, biological treatment via conventionally-activated sludge, chlorination and pH adjustment, reducing solids and Biochemical Oxygen Demand (BOD). For some reuse applications, such as turf irrigation, conventional treatment may be all that is needed.

ADVANCED TREATMENT PROCESS

When a conventional treatment process isn’t adequate for meeting the required treatment standards, advanced treatment technologies can be implemented. These technologies go further to remove contaminants that conventional treatment processes can’t. They are arranged for specific needs, including:

- Removal of solids and bacteria via microfiltration or ultrafiltration membranes.

- Biological nutrient removal with sequencing batch reactors (SBR) or membrane bio reactors (MBR).

- Removal of dissolved organics or salts with reverse osmosis.

- Removal of trace contaminants and pathogens via oxidation and disinfection.

- Removal of dissolved organics and contaminants via an adsorption process or ozone-enhanced biological active filtration. ■

REFERENCES

Shiklomanov, Igor. “World Fresh Water Resources.” Water in Crisis: A Guide to the World’s Fresh Water Resources. Ed. Peter H. Gleick. 1993. Print.

The Water Resources Group. Background, Impact and the Way Forward. Rep. 26 Jan. 2012. 16. Web.

[divider]

ABOUT THE AUTHORS

Nate Maguire is the Americas business unit director, industry, and agriculture for Xylem’s applied water systems business unit; Greg Claffey is Xylem’s director of treatment sales, North America; and Keel Robinson is Xylem’s North America reuse marketing and business development manager. Xylem’s well-known global brands provide world-class products, comprehensive solutions, and unmatched applications expertise in more than 150 countries. To implement a water reuse system in your facility, visit www.xyleminc.com/food.

MODERN PUMPING TODAY, August 2014

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!