In the parts 1 and 2 of this series, we examined the benefits of reusing wastewater and the biological and disinfection processes available to plants who pursue treatment options for a specific need. However, treating water is only the first step to ensuring wastewater is recycled and reused efficiently and effectively within a plant because the transportation and storage of water reuse is also important. In this installment, we’ll take a detailed look at the choices and options that make a water reuse system a desirable option for plants, including the essential keys to consider when moving from planning to implementation.

ENSURING EFFICIENT AND EFFECTIVE WASTEWATER REUSE

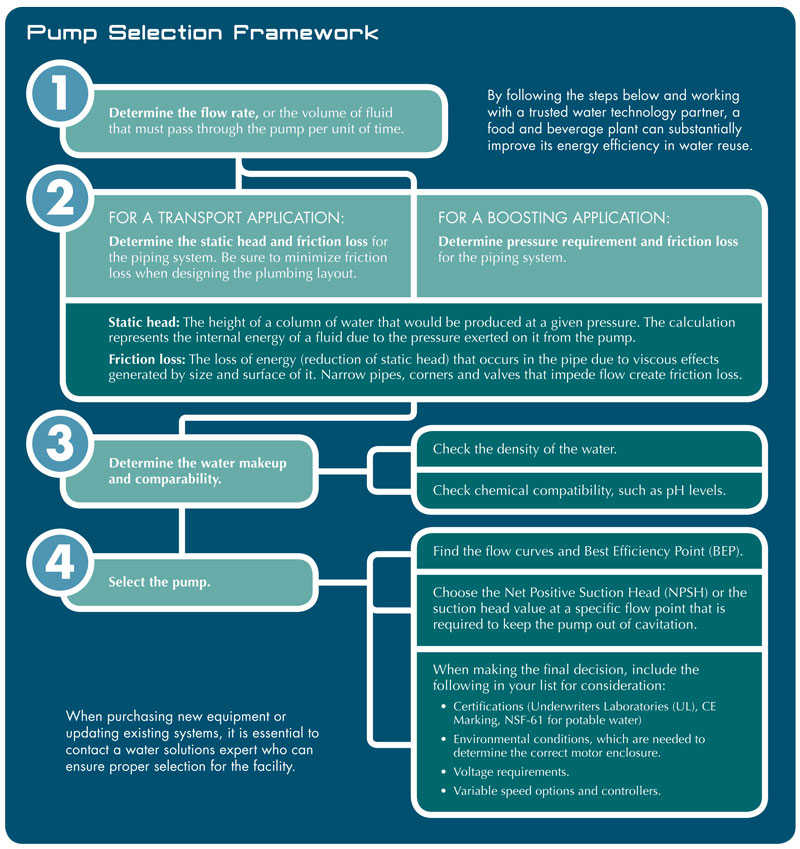

Treatment and pumping systems are primary energy consumers within a water or wastewater loop. Sizing the system and selecting the right equipment to meet specific reuse requirements are critical to maximizing energy savings over the life of the equipment.

Pumps serve two purposes in a reuse system: transporting and pressure boosting. Water needs to be moved from one location to another for treatment, storage purposes, or for use. Pressure boosting is required for some treatment technologies, including reverse osmosis (RO), where specific pressures are required to move water through a membrane. Many reuse applications, such as irrigation and equipment washing, also require boosting capabilities.

SELECTING THE RIGHT PUMP

The pump and piping selection can have a considerable impact on the energy consumed over the course of the system’s life. Pumps should be selected to operate at their Best Efficiency Point (BEP) and the plumbing should be engineered to minimize friction loss. A leader in global water technology, Xylem, estimates that a water reuse system using improperly sized piping and pumps can increase energy consumption by 200 to 300 percent.

IMPLEMENTING A WATER REUSE SYSTEM

- Define Objectives: When deciding what type of water reuse system is needed in a facility, a plant must define its objectives both from sustainability and cost perspectives.

- Select Applications: Next, plant owners and/or operators should define the applications for which the water will be used. It is best to start with high-volume reuse applications that have lower water quality requirements, therefore requiring less treatment, such as landscape irrigation. By following this approach, the facility will achieve the greatest return on investment, as higher levels of treatment drive costs up.

- Determine Treatment Levels: Finally, determine the treatment levels required for the selected applications by measuring current wastewater quality to establish a baseline, and then compare that to the quality level required for the selected applications. This gap in water quality will determine the treatment intensity.

SUSTAINABILITY

With increased reports of drought in the news, water reuse is at the forefront of how businesses can expand sustainability efforts and help ensure the available water supply. Beyond water shortage, there is also greater focus on social responsibility and water stewardship. In part, due to public indices such as the Dow Jones Sustainability Index, companies are investing more heavily in their sustainability efforts than ever before and are better managing their water use.

HEALTH AND SAFETY

Another driver of water reuse is health and safety mandates. Food and beverage operations must comply with the Food and Drug Administration (FDA), as well as the EPA and other relevant regulatory bodies. These standards put in place by these organizations to regulate wastewater quality vary, but apply in some form to all plants, regardless of size. For example, in 2012, the EPA released a document outlining state and federal water reuse guidelines for all industries, including food and beverage processing (see reference 4).

Any company that operates in a foreign country should also be aware of international regulatory bodies and standards. Reuse mandates vary from country to country, but many businesses are looking to the U.S. and Europe as examples of countries implementing regulations that could impact them.

THE TAKEAWAY

There are five key takeaways regarding water reuse in food and beverage facilities.

Water scarcity is a serious challenge: While the earth’s population continues to increase, readily useable water supply is decreasing. Many businesses, regardless of size, are using water reuse to help fill this gap.

Water reuse solutions mitigate business risk: Reuse systems enable companies to become less reliant on source water from aquifers and local municipalities, thereby lowering their risk of supply disruption and future water tariff increases.

Multiple treatment options are available for specific needs: There are a variety of conventional and advanced treatment processes that can be configured for each facility and tailored to be fit-for-purpose depending on the application.

Choosing the right equipment results in long-term benefits: A plant’s total water and wastewater costs are significant and will continue to rise due to the factors described in this white paper. Employing the correct reuse technologies can result in both hard and soft savings for your organization, including reduction in supply risk and benefits to the environment.

Collect the necessary information to start the process: Now that you’ve decided to start reusing water, the first step is to define your objectives. Consider both your financial and environmental goals. ■

REFERENCES

1. Shiklomanov, Igor. “World Fresh Water Resources.” Water in Crisis: A Guide to the World’s Fresh Water Resources.Ed. Peter H. Gleick. 1993. Print.

2. The Water Resources Group. Background, Impact and the Way Forward. Rep. 26 Jan. 2012. 16. Web.

3. EMD Millipore. “Filtration Basics.” Millipore Membranes and Filtration. Web.

4. United States. Environmental Protection Agency. 2012 Guidelines for Water Reuse. Sept. 2012. Web.

5. The Coca-Cola Company. 2012/2013 GRI Report “Water Stewardship.” Rep. Web.

About the Author

Nate Maguire is the Americas business unit director, industry, and agriculture for Xylem’s applied water systems business unit; Greg Claffey is Xylem’s director of treatment sales, North America; and Keel Robinson is Xylem’s North America reuse marketing and business development manager. Xylem’s well-known global brands provide world-class products, comprehensive solutions, and unmatched applications expertise in more than 150 countries. To implement a water reuse system in your facility, visit www.xyleminc.com/food.

MODERN PUMPING TODAY, October 2014

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!