In part 1 of this series, we introduced how one small town in Oregon has taken a creative and innovative approach to ensure optimal performance at its water treatment facility, and had turned to ZAPS Technologies of a Corvallis, Oregon. Developed by ZAPS Technologies specifically for online monitoring, the LiquID station uses Hybrid Multispectral Analysis (HMA)—a combination of in situ fluorescence, absorption, and scattering measurements in a single flow-cell to continuously characterize chemical bonding and molecular structure. Emergent water treatment technologies like this continue to revolutionize the way we view our world and the ways in which our municipalities address their most pressing environmental and efficiency concerns.

CONVINCING THE STAKEHOLDERS

Public Works Director Eric Quinn’s challenge then became convincing his funding sources that this emergent technology merited the investment. “Once I had my mind made up and was able to describe the advantages of realizing real-time data to the City Council, there was no holding me back. The funding agency needed the vision explained outlining the obvious advantages of being able to optimize treatment. Improved water quality was the goal and what or who offered a better mechanism to attain that?”

Hoping that the chance might present itself, Quinn worked with the engineer to make some subtle changes that would allow the LiquID stations to be installed at the end of the project very simply and without any issues.

“When Federal USDA Grant Funds from our wastewater plant upgrade became available, I took advantage of the opportunity and convinced the funding agency of the value that ZAPS could have on their investment.

“The installation and set-up went without a hitch and the set-up personnel were very helpful in explaining how to utilize the equipment. The biggest problem was learning how to efficiently pump the sample to the equipment at the relatively low flows required by ZAPS without creating cavitation issues and potential plugging caused by the very characteristic nature of wastewater,” says Eric.

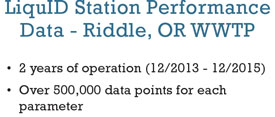

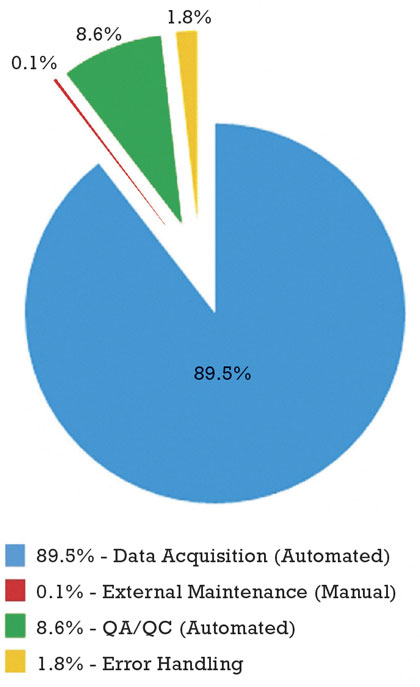

The LiquID station at Riddle went online on December 2013. Its reliability and performance has been impressive.

Follow-up visits from the funding agency’s representatives were numerous. It didn’t take them long to see the obvious advantages.

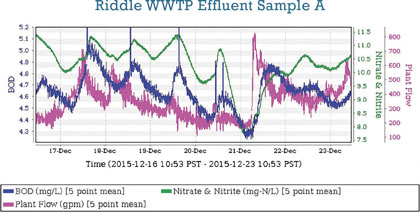

There has always been an understanding among plant operators of the relationship between ammonia and nitrate, but the ability to visualize that interaction through real-time trending brought it home to those observing the real-time data from the Riddle, Oregon plant. Several test results a week vs. thousands of sample characterizations performed by the LiquID station, allowed the staff to optimize the ammonia removal process and regulate efficient blower operation by analyzing the data with a click of the mouse.

Eric goes on to explain, “The LiquID station is monitoring our effluent. The WUI site is constantly up on the computer which gives us the ability to glance at the level of treatment at any moment. I like to utilize the trend charts so I can tell where we have been and where we are headed. Once you get your plant working and feel satisfied with your results, small changes in process management allow you to fine tune the system achieving a level of water quality that in the past relied heavily on luck.”

The Web User Interface (WUI)–included without additional charge as part of the instrumentation purchase – clearly displays all current and trending data and make all the Riddle, Oregon WWTP’s historical data immediately accessible. “The tools available to the user on this site are nothing short of amazing to me,” says Quinn. The ZAPS Technologies WUI gives operations staff the ability to review long-term comparable data to help them make decisions on performance optimization options. As Eric puts it, “This has made the difference from good performance to great performance possible.”

Asked what ultimately has come of being able to monitor his plant’s process in with multi-parameter real-time data acquisition Quinn is emphatic, “I am grateful be able to have in my arsenal of tools, the capability to manage our processes just that little bit better and with that higher level of confidence than I had using only our conventional monitoring methods. ZAPS has allowed us the ability to immediately measure and assess our successes and failures when it comes to refining our wastewater process. How cool is that?!!

“What greater tool placed in the operator’s toolbox is there than real-time data? Operational decisions must be based on sound science, experience and knowledge. ZAPS technology gives operations staff the capability to position all those fundamentals at their fingertips and use them in a way only dreamed about not too many years ago. The installation of a LiquID machine at our facility has allowed us the luxury of process refinement and true optimization management.”

Still, Quinn has his sights set on even better performance and hopes to be able to eventually further refine his facility’s process with additional LiquID Stations installed to monitor other key aspects of the plant. He refers back to Corvallis, Oregon, a city of 55,000 where the early adoption of three LiquID stations and critical decision making helped reduced disinfection chemical costs by 62 percent and has managed to save the city approximately $75,000 in one year. For Eric, that’s all the information he needs to keep his eyes on the charts and monitoring the water he protects in a new light. ◆

For More Information:

The LiquID Station from ZAPS Technologies is an innovative, optical instrument for continuous water quality monitoring. The automated online instrument analyzes a continuous flow-through stream from a pressurized water sample line using hybrid multi-spectral analysis (HMA), and uses no reagents nor produces any waste other than the original sample (which is returned or wasted as appropriate). With this method, the LiquID station is capable of monitoring a wide range of water quality parameters in a number of different industry applications, including those relevant to municipal water and wastewater treatment, water reuse systems, and industrial process control. For more information, visit www.zapstechnologies.com.

____________________________________________

MODERN PUMPING TODAY, October 2016

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!

![]()