SEW-EURODRIVE

P2.e Planetary Gear Units

SEW Eurodrive announces a major expansion in its U.S. manufacturing capability with the local assembly of its advanced P2.e planetary gear units, now available with lead times as short as six weeks in two-stage and three-stage cataloged ratios and as little as twelve weeks for non-stocked options. The P2.e planetary gear unit series is engineered to deliver maximum torque in a compact footprint, with optimized fan-cooling options and new, modular motor inputs that do no longer require a pre-stage gearbox. For more information, visit www.seweurodrive.com.

ELKAY

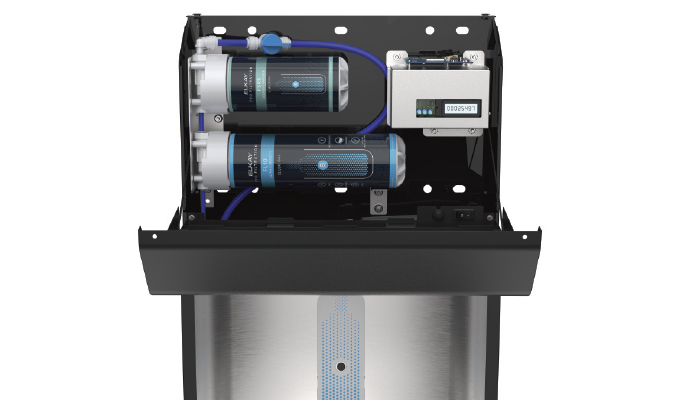

Pro Filtration Bottle Filling Station

Pro Filtration is designed to save time and cut costs. The new design houses filters at the top of the unit, allowing for filter changes in under thirty seconds. The included filters are ultra-capacity which provide filtration on up to 10,000 gallons; filter changes are only needed once a year. An optional sediment prefilter assists in reducing sediment buildup caused by the municipal water supply. The system detects newly installed filters and will automatically reset the filter status lights and flush the system. For more information, visit www.elkay.com.

ABB

SACE Emax 3 Air Circuit Breaker

The new SACE Emax 3 air circuit breaker will improve energy security and resilience of power systems in critical infrastructure—including data centers, factories, hospitals, and airports. This cutting-edge breaker includes sensing, intelligence, and advanced algorithms to provide predictive maintenance. Aimed at large facilities with high power demands, the innovative Emax 3 is designed to address increased concerns about grid stability, cybersecurity, and the surging power needs of AI in data centers. For more information, visit www.abb.com.

FINISH THOMPSON

DB Series Sealless Mag-Drive Pumps

The DB Series combines a close-coupled design with robust polypropylene or PVDF construction, ensuring safe and reliable handling of highly corrosive chemicals while minimizing downtime due to corrosion. Every model is equipped with powerful neodymium magnets, providing strong, efficient, and dependable power transmission. The pump’s replaceable shaft and bushing make maintenance straightforward and cost-effective, extending the operational life of the equipment. With a back pullout design, the DB Series allows for easy maintenance without disconnecting piping, further reducing downtime and labor costs. For more information, visit www.finishthompson.com.