Food and beverage processing plant operators looking to add vitamins, colors, flavors, fragrances, enzymes, and preservatives into their processes have a new option available in the benefits from Fluid Metering, Inc.’s (FMI’s) valveless piston technology. Valveless metering pumps provide precision dispensing of additives for food processing applications—often in concentrated form, FMI pump’s precision of 0.5 percent ensures product consistency, while eliminating waste of expensive ingredients.

ELIMINATING VALVES, IMPROVING PRECISION

FMI’s patented valveless CeramPump® pumping principle utilizes one moving part, a sapphire-hard ceramic piston, to perform all fluid control functions, eliminating valves typically present in other low volume metering technologies. Elimination of valves, as well as having dimensionally stable ceramic internals, results in a pump that will provide millions of maintenance-free dispenses without the need for recalibration.

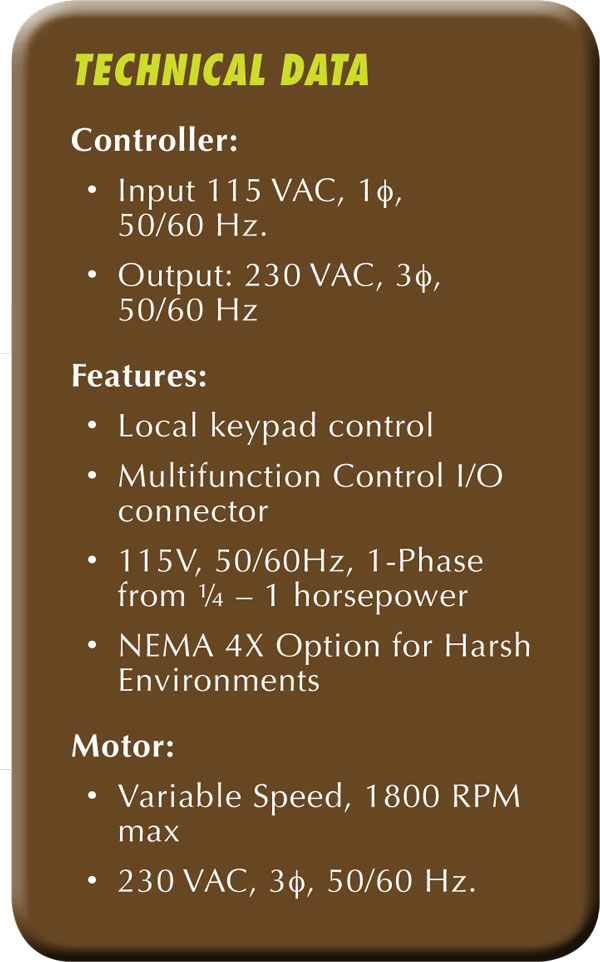

The IVSP Industrial Variable Speed Metering Pump is ideal for viscous fluids. It has a rugged ¼ horsepower variable speed drive motor and available with sanitary quick-disconnect fittings. Speed is controlled via a DIN mountable controller for both manual and electronic speed control.

SYNCHRONOUS ROTATION AND RECIPROCATION

The valveless function is accomplished by the synchronous rotation and reciprocation of the ceramic piston within a precisely mated ceramic liner. The reciprocation action of the piston, similar to a standard piston pump, accomplishes the pumping function. However, that’s where the similarity ends.

The piston also rotates, alternately aligning a flat at the end with the inlet and outlet ports of the pump. When the flat is aligned with the inlet port, fluid can be drawn into the pump. When the flat is aligned with the outlet port, fluid can exit the pump. Only one port is open at any time and at no point are both ports interconnected. This effectively functions as, and replaces, conventional check valves.

A COMPLETE PACKAGE

The Industrial Variable Speed Metering Pump’s variable stroke rate pump system for industrial process applications uses a high torque 3 phase variable speed drive, which is ideal for handling a broad range of fluid viscosities. The complete metering system consists of a valveless pump head module, a high torque drive module, and a control module. The pump head is integrally mounted to the drive and the control module is connected to the drive via a 4 conductor cable.

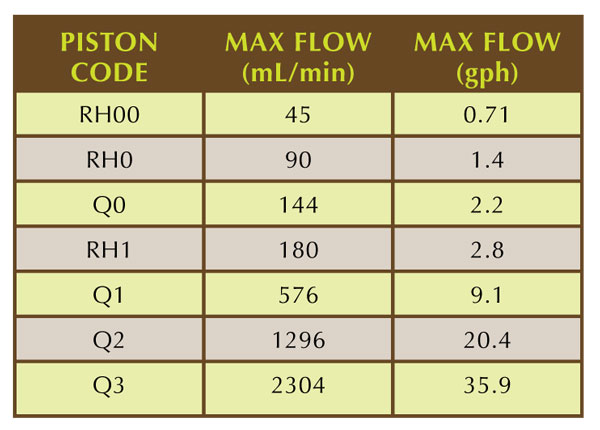

The control module has a 3 digit LED display corresponding to frequency – 2 Hz (60 rpm) minimum, 60 Hz (1800 rpm) maximum. Motor speed can be adjusted either manually using the convenient front panel membrane switches, or electronically using a 0-20 mA, 4-20 mA, or 0-10VDC input signal. Additional control functions include start, stop, acceleration, forward, and reverse. Flow rate is determined by the combination of drive speed, piston size, and pump head displacement.

For over fifty-five years FMI pumps have been used food and pharmaceutical processing; medical, analytical and laboratory instrumentation; industrial process, water and wastewater treatment, environmental monitoring, and much more. ■

About the Author

Herb Warner is the marketing manager for Fluid Metering, Inc. For more information call 800.223.3388 or 516.922.6050, fax 516.624.8261, email pumps@fmipump.com, or visit www.fmipump.com.

MODERN PUMPING TODAY, October 2014

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!