For more than half a century, Italy has taken a leading role in Europe in identifying and utilizing alternative fuels that can power motor vehicles. The roster of alternative fuels available to Italian drivers sounds like the ingredients of a very tasty “alphabet soup”: LPG (or Autogas), CNG, and LNG, the latter two of which are often referred to as “metano,” which is the Italian word for “methane.”

As the demand for “green” fuels continues to grow—with federal regulations (European Directive 2014/94/UE) in large part driving this growth with their requirements that retailers offer something other than traditional gasoline (petrol) and diesel fuel-Italy is now home to more than 4,200 stations that offer Autogas, 1,050 with access to CNG, and twenty with LNG filling points.

Retailers who must now offer alternative fuels also find themselves faced with another challenge: updating their sites with equipment that is not only capable of handling the unique dispensing characteristics of, for example, Autogas, but also creating a storage-and-dispensing system that is sensitive to the needs of surrounding homes, schools, and businesses.

“More and more customers are driving vehicles powered by alternative fuels and they must be made available to them,” explains Giorgio Gotta, general manager of GasTech Services s.r.l., Bari, Italy, a leading consulting and engineering firm that provides pumping equipment and site services to many customers (oil companies, private networks, etc.) all over Italy. “However, at service stations that are located near houses and businesses in the center of a city there are regulations that limit the amount of noise pollution that can be created by industrial operations, while mandating that overall site safety also be of the highest importance.”

One such site that faced the demands of supplying Autogas while meeting established noise and safety standards was an EWAPOINT service station in the town of Santa Maria Capua Vetere, which is situated about 22 miles due north of Naples and a comparable distance from the famous Mount Vesuvius volcano. Recently, the operators of the station wanted to begin offering Autogas to their customers.

“Because there are numerous houses and apartments located next to the station, there are regulations that demand a minimum safety distance between the Autogas tanks and dispensers and the homes,” says Gotta. “In some instances like these, it is sometimes impossible to meet the regulatory demands and you can’t offer Autogas service, but if you can look for a clever solution, you may be able to find a way to make it possible.”

For assistance, Gotta turned to Luigi and Graziano Pastore, the founders and managers of G.P. s.r.l., which is based near Naples in the city of Pomigliano d’Arco. G.P. is a long-time designer and installer of Autogas systems for Italian fueling sites. After surveying the site, the Pastores determined that the Autogas islands and dispensers would need to be placed away from the existing covered forecourt. Regulations noted that the Autogas could be stored in and dispensed from an underground storage tank (UST)—with a capacity of 6,600 gallons—which would, in this case, be buried behind the site’s office/retail shop.

However, there was not enough room between the shop and a vehicle pressure-cleaning station at the rear of the property to bury the UST in a horizontal orientation. Using some of that “clever” thinking that Gotta previously mentioned, it was decided that the UST could be installed vertically in order to satisfy the Italian regulations.

“To ensure sufficient capacity, we needed a tank—which would be 16 feet tall—that could hold 6,600 gallons, and it had to be a UST,” says Gotta. “After considering the alternatives, we realized that the only available solution was to use a vertical tank.”

FINDING THE PERFECT PUMP

After working out the logistics of the installation, the next step was finding a pump that could safely and quietly transfer the Autogas to the four fueling nozzles—oftentimes simultaneously—that are located at the fueling island and into the vehicle’s fuel tank.

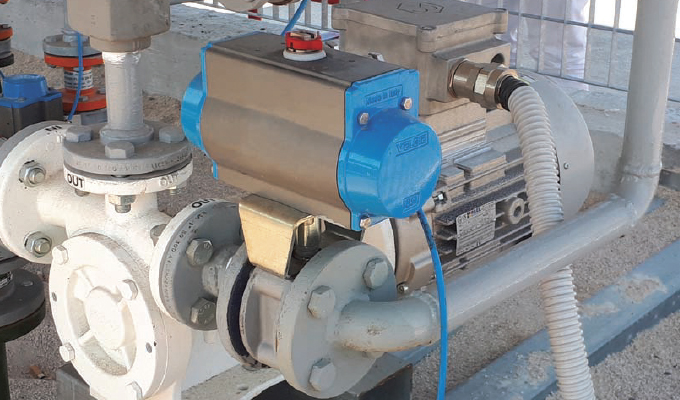

Based on past experience, the decision was made to install an RC40 Series Regenerative Turbine Pump from Ebsray®, Cromer, Australia (Ebsray is a product brand of PSG®, a Dover company).

“The challenge was to select a pump that could run reliably in these conditions,” says Graziano Pastore. “We have had positive experiences in the past working with Ebsray RB10 and RX submersible pumps, so we know that Ebsray pumps can supply the priming and 15.7 feet of suction lift that would be needed in this installation.”

A key consideration was that the pump would have to be able to create at least 10 bar (145 psi) of differential pressure in order to be able to transfer the Autogas from the UST to the dispenser. That can be a challenge for other pump technologies, especially in the warm southern Italian months, when high temperatures will increase the internal pressure in the vehicle’s fuel tank to a level that forces the pressure in the UST to also increase. This means that as much as a 7 or 8 bar (102 to 116 psi) differential pressure is needed in order for the fueling process to commence. If the proper differential pressure is not attained, it becomes difficult for the pump at the dispenser to transfer the fuel into the vehicle’s tank, leading to slow filling rates, or even the loss of service.

The Ebsray RC40 pumps fits the needs of this installation perfectly because it can create differential pressures up to 14 bar (200 psi) at motor speeds up to 3,500 rpm with maximum flow rates of 53 gallons per minute. In this specific installation, an electric motor that can produce 2,900 rpms with a maximum differential pressure of 14 bar and a maximum flow of 44 gallons per minute is being used.

The RC40 is able to deliver this performance because it features a single-stage bronze impeller (with ductile iron optional) that provides high performance with low, affordable maintenance, which is ensured by its cartridge-style mechanical-seal technology. The close-coupled NPT, ANSI, or DIN flange mounts to both 50Hz and 60Hz NEMA and IEC electric motors. The unique three-port design with two discharge ports allows for operational flexibility with lower installation costs. Finally, the RC40 pump complies with ATEX, UL51, and AS1596 regulatory codes for use in potentially explosive atmospheres.

CONCLUSION

The installation was completed in June 2018 with the first Autogas dispensed in July, the culmination of a process that brought together the best of the pump producer (Ebsray), distributor (GasTech Services), site outfitter (G.P.), and end user (EWAPOINT) to create an Autogas-dispensing solution that can satisfy both the availability and regulatory needs of a tricky site location.

“The site is operating perfectly with an average of 90 seconds needed to dispense 13.2 gallons at 10-bar differential pressure,” says Gotta. “Already, they are making plans to construct a second pump island that will allow them to operate up to eight nozzles simultaneously. This success could not be possible without the assistance of the RC40 Series Regenerative Turbine Pump from Ebsray. Mission accomplished!”

FOR MORE INFORMATION

Siemens Digital Industries Software, a business unit of Siemens Digital Industries, is a leading global provider of software solutions to drive the digital transformation of industry, creating new opportunities for manufacturers to realize innovation. With headquarters in Plano, Texas, and over 140,000 customers worldwide, we work with companies of all sizes to transform the way ideas come to life, the way products are realized, and the way products and assets in operation are used and understood. For more information, visit www.sw.siemens.com.

Jean-Marc Bernard is the EMEA–senior market manager LPG Europe for Ebsray® and PSG® and can be reached at jean-marc.bernard@psgdover.com. Ebsray is a leader in the design and manufacture of regenerative turbine and positive displacement pump technologies, including sliding vane and gear, for a wide range of industrial applications. Founded in Brookvale, Australia, Ebsray has grown into a leading supplier of specialized pumps for use in a wide array of industries, including chemical, petroleum liquids, mining, food and beverage, pulp and paper, municipal and utility services, and paint and coatings. Ebsray is a product brand of PSG®, a Dover company. PSG is composed of several leading pump brands, including Abaque®, All-Flo, Almatec®, Blackmer®, Ebsray®, EnviroGear®, Griswold®, Mouvex®, Neptune™, Quattroflow™, RedScrew™, and Wilden®. For more information, visit www.psgdover.com.

MODERN PUMPING TODAY, July 2019

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!