In the sometimes messy business of food and beverage procssing, liquid ingress protection is a critical element in keeping your electrical systems operational. Exposure to water in applications, condensation and accidental spills of machine oils and lubricants can all shorten the life of your electrical system. Effective protection of your electrical system can mean the difference between consistent operations, or unscheduled downtime while liquid-damaged components are replaced or the system is rebuilt. Thankfully, the innovators at ABB have addressed this and other vital processing concerns with their newest product line.

KEYS TO THE THREE-LEAD DESIGN

- Streamlined three-lead electrical connection

- 360-degree rotatable conduit box

- 1-5 horsepower, three-phase designs

A NEW DESIGN

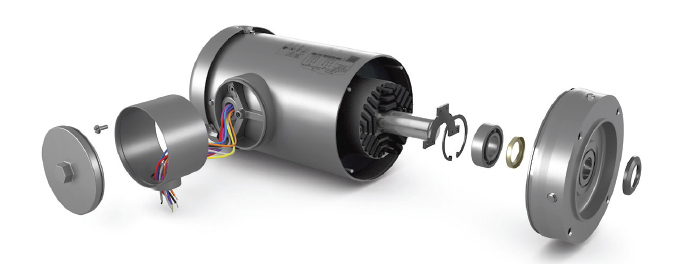

ABB, the world’s leading manufacturer of NEMA motors, has elevated its Baldor-Reliance Food Safe stainless steel motor product portfolio with a streamlined three-lead electrical connection design, delivering a superior experience for food and beverage processing operations. This new motor solution is engineered to simplify installation, enhance reliability and improve workplace safety—all while seamlessly integrating with existing 460V systems.

“This new configuration of the Baldor Reliance Food Safe stainless steel motor is a testament to ABB’s commitment to supporting our customers with reliable, efficient and industry-leading technology,“ said Brandon Canclini, global product manager for ABB’s NEMA Motors Division. “ABB is dedicated to developing solutions that address the unique demands of food processing environments.”

EASY SET-UP, EASY OPERATION

The optimized design reduces installation time and simplifies the setup process. By minimizing the number of leads, the risk of connection errors decreases, resulting in greater reliability with fewer interruptions. These enhancements will allow facilities to boost productivity while lowering maintenance costs and reducing downtime. The nine-lead configuration is still available for variable speed drive operation and more complex electrical systems.

The Baldor-Reliance Food Safe stainless steel product lineup, featuring 1 to 5 horsepower, three-phase motors, is engineered to meet diverse operational needs with advanced performance and durability. The stainless steel enclosure features smooth, crevice-free surfaces and a self-draining design, preventing food particle buildup, ensuring thorough cleaning and minimizing contamination risks. Additional features, such as welded feet, a polished 360-degree rotatable conduit box and smooth external drains, further enhance sanitation efficiency.

KEEPING ELECTRICAL SYSTEMS SAFE

All Baldor-Reliance Food Safe motors are built with corrosion-resistant stainless steel, providing IP69 ingress protection and withstanding high-pressure, high-temperature washdowns while exceeding rigorous sanitary standards. The design eliminates the need for motor shrouds, offering full 360-degree access for inspection and cleaning.

This motor line is available in C-Face foot-mounted and footless designs, offering flexibility to meet diverse operational needs. Encapsulated, color-coded leads and a laser-marked nameplate enhance usability during installation and maintenance. Designed to NEMA Premium® efficiency standards, the motors deliver exceptional energy savings, combining cost-effectiveness with dependable performance.

SETTING THE STANDARD

The three-lead motors are constructed from 300-series stainless steel and designed for inverter use per NEMA MG1 Part 31.4.4.2. They deliver exceptional performance across a wide range of applications. Each motor is backed by a three-year warranty, reflecting ABB’s commitment to quality and reliability.

ABB is a global technology leader in electrification and automation, enabling a more sustainable and resource-efficient future. By connecting its engineering and digitalization expertise, ABB helps industries run at high performance, while becoming more efficient, productive and sustainable so they outperform. At ABB, we call this „Engineered to Outrun.“ The company has over 140 years of history and more than 105,000 employees worldwide. For more information, visit www.abb.com.