The specialist for combined heat and power plants and biomethane plants, ETW Energietechnik from Moers, Germany, has optimized the delivery program of its proven biogas upgrading system, ETW SmartCycle PSA, for worldwide use on biogas and waste fermentation plants. The aim of the development was a significant reduction of investment costs as well as execution time. With the new plant standard, the effective upgrading process can be adapted even more specifically and economically to the respective application areas.

MODULAR AND ADAPTABLE

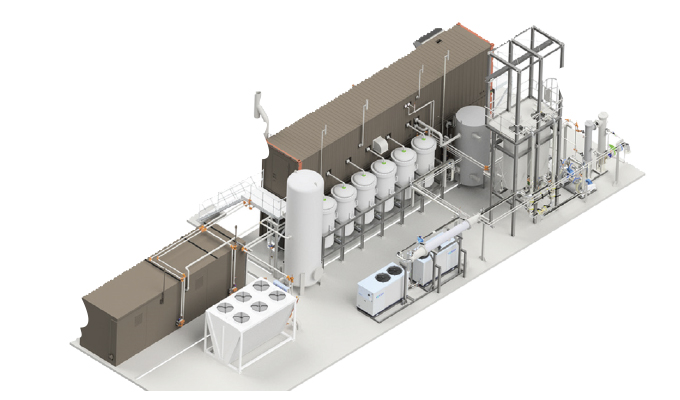

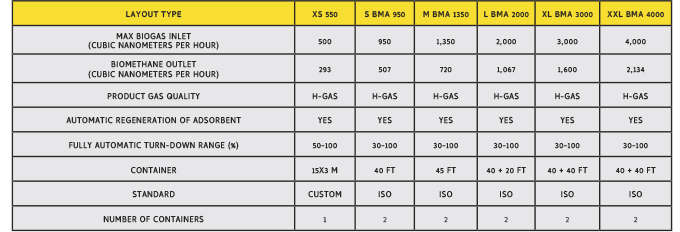

The new modular concept for upgrading biogas to natural gas quality is based on a modular system consisting of ISO standard containers in the standard sizes 20, 40, and 45 feet. With six standardized systems, the delivery program serves plant sizes with a raw gas capacity of 550 up to 4,000 cubic nanometers per hour.

“The result is a compact biogas upgrading system that is also well suited for large biogas volume flows,” says product manager Sayethan Kirubaharan, explaining the purpose of the relaunch.

HITTING THE STANDARD

ISO standard containers not only reduce transport costs but also make bureaucracy very uncomplicated—regardless of whether transport is by road, rail, or sea. All container modules are prefabricated at ETW Energietechnik‘s plant in Moers and assembled in the newly built 32-foot-high production hall exactly as they will later be erected on site.

This manufacturing principle means that all strategically important intermediate elements such as connecting parts, piping, and external units such as cooling systems and activated carbon filters can be perfectly matched.

“ETW Energietechnik supplies the plants in accordance with both the Pressure Equipment Directive 2014/68/EU and the ASME standard for worldwide use,” adds Kirubaharan.

All assemblies are delivered to the construction site in prefabricated modules, so that the plant is ready for operation just two weeks after delivery.

BUILDING ON SUCCESS

This new plant reduces costs by an average of around 15 percent compared to custom-made products; production and installation time on site are reduced by around 30 percent overall. The general benefits of the ETW SmartCycle PSA, such as minimal energy requirements, maximum turndown flexibility, long component service life, and low maintenance requirements, remain.

FOR MORE INFORMATION

ETW Energietechnik’s highly efficient systems enable it to generate electricity and heat wherever it is needed. With solutions for processing and feeding biogas as biomethane into the natural gas grid, it also creates ways to make sustainable energy usable where it is consumed but cannot be generated. With around 120 highly qualified staff, ETW Energietechnik has been developing and producing energy systems of all kinds and sizes at its Moers location for energy suppliers, agribusinesses, local authorities, and industrial companies since 1997—with creativity and ideas, technical knowledge, and innovation. For more information, visit www.etw-energie.de.

MODERN PUMPING TODAY, August 2022

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!