By Peter Schüten, Almatec

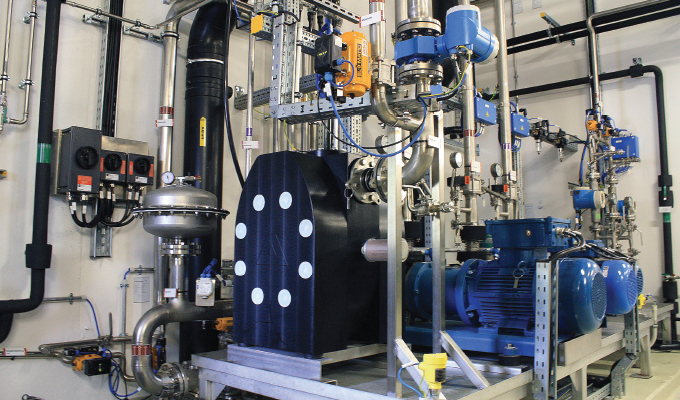

When first learning about air-operated double-diaphragm (AODD) pumps, many people are left asking how they are able to excel in so many diverse applications. The success in this enormous application range, and consequently the popularity of AODD pumps, lies in the pump’s design characteristics. These characteristics include:

- Simple startup

- Self-priming capability

- Resistant to dry running and runs smoothly with solids

- Gentle displacement pumping

- Continuously adjustable via controllable air volumes

- Self-adjusting when the medium changes

- No drives or rotating parts in the pumped medium

- No shaft seals

- Overload-proof—if the counter-pressure equals the drive-air pressure, the pump stops and restarts when the pressure drops—without regulation or monitoring via mean supply response time (MSRT) devices

- Easy to use in ATEX areas

- Current-less drive via compressed air

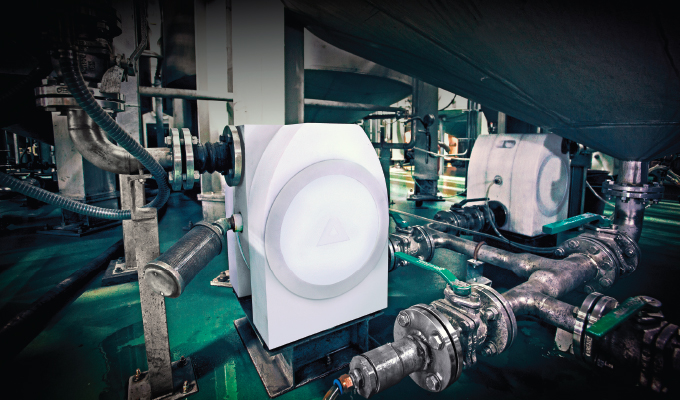

The first two characteristics—simple startup and self-priming—help explain why AODD pumps are so flexible. Part of this flexibility includes easy installation. Since there is no need to align the pump when changing locations, installation can be performed by simply standing the pump upright and connecting the fluid lines and air supply. And unlike other types of pumps, there is no need to prime an AODD pump. Therefore, rather than the laborious and, depending on the liquid, dangerous process of bringing the medium into the pump manually, the pump simply fills itself during operation by sucking the medium out of the receiver.

SIMPLICITY IN ACTION

Once in operation, an AODD pump is not only easy and simple to control, it also does not require any control electronics and/or expensive frequency converters, which might cause the motor temperature to rise during slow running without a forced cooling fan (critical for ATEX). Instead, the air volume and the pump flow rate are simply regulated with a needle valve. In addition, if, for example, the density or viscosity changes due to the temperature, the pump will automatically run slower or faster without damage to the pump or without the loss of liquid, as is the case with internal pump slip or a magnetic coupling that can tear during operation. And if the liquid fails to flow, for example, because the tank is empty, it simply continues to run dry.

REDUCING RISKS THROUGH GENTLE HANDLING

Another important design characteristic of the AODD pump is gentle displacement pumping. This characteristic stems from the fact that these pumps allow solids of considerable size to pass through them, resulting in very gentle pumping and low shear. And because AODD pumps do not contain any drive parts or other rotating parts within the fluid, there is no need to worry about damaging the shaft seal. Operational risks and the need to maintain mechanical seals (including the use of additives for flushing, etc.) are also eliminated. Instead, a purely static seal takes effect, which is “hermetically sealed” according to guidelines from the German Technical Guidelines on Air Pollution.

It’s also important to mention that an AODD pump is overload-proof. This means that the pump can only build up as much pressure as you give it via the drive air pressure, which, for example, can be the maximum permissible pressure of your filter. If the outlet pressure reaches the drive air pressure, the pump simply stops, meaning that there is no danger of the pump or the line bursting if the pressure line is blocked. This results in overload protection for lines/filters and a simple on-off operation via valves in the medium.

There is not a risk of sparks from an electric drive, also self-heating is not an issue, and static charges can be dissipated via the pump’s conductive materials (as well as plastic). This also makes AODD pumps ideally suited for use in hazardous areas (ATEX) and mobile applications. Light and compact, these pumps are also simple to install in hazardous areas and can even operate with stored air in the case of an emergency.

HIGH PERFORMANCE AND HIGHLY ADAPTABLE

Another key characteristic of an AODD pump is its enormous range of pump materials and their possible combinations. The interior of an AODD pump can be manufactured in a large number of elastomers and thermoplastics, from “black rubbers” such as neoprene or Buna-N to PTFE. The pump’s housing can be manufactured in various metals, ranging from cast iron and aluminum to high-grade stainless steels. The housing can also be manufactured in a variety of plastics, including high-performance plastics such as PTFE or PEEK.

Therefore, depending on the mechanical/chemical properties or the temperature of the medium, the pump can almost always adapt to the application. And the fact that the pump is constructed in a solid-block design also provides additional design advantages when it comes to safety, including high stability and rigidity, static weight, and smooth and highly chemical-resistant surfaces.

MAKING THE AODD CHOICE

In conclusion, if you’re looking for a pump that is flexible; simple to start up, control and maintain; that is overload-proof and self-adjusting without regulation; that can handle highly aggressive and/or solids-laden media without damage (even in hazardous areas); that can suck in medium when it is dry and also run dry; and that is also comparatively cheap to purchase and maintain; then an AODD pump is the perfect choice for you.

FOR MORE INFORMATION

Peter Schüten is the product management director for Almatec®, a leading manufacturer of air-operated double-diaphragm (AODD) pumps. He can be reached at peter.schuten@psgdover.com. Almatec is a product brand of PSG®, a Dover company. PSG is comprised of leading pump brands, including Abaque™, All-Flo, Almatec®, Blackmer®, Ebsray®, em-tec, EnviroGear®, Griswold®, Hydro Systems, Mouvex®, Neptune™, Quantex™, Quattroflow™, RedScrew™, and Wilden®. For more information, visit www.almatec.de or www.psgdover.com.

MODERN PUMPING TODAY, November 2021

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!