Force Control Industries introduces the PosiClutch 200 Series PTO clutch, a hydraulically actuated microprocessor-controlled Oil Shear PTO clutch which is ideal for high volume pump applications. Designed to mount on a diesel engine with SAE 00 flywheel housing, this versatile clutch can include up to four pump pads to drive additional hydraulic pumps, up to 400 horsepower. Advanced engineering design eliminates the need for separate transmission fluid cooling equipment, thereby eliminating components, hoses and fittings which can leak and fail. At just 33¼ inches in length, including sheave support bracket, this is the most compact package available—reducing overall footprint and weight. The PosiClutch 200 Series PTO is ideal for high volume pumps such as high-volume emergency flood water control, on barges and workboats, and more.

SIMPLE DESIGN YIELDS BIG BENEFITS

- Each PosiClutch clutch consists of seven basic components:

- The input shaft which is connected to the motor or engine

- The output shaft which is connected to the load

- A clutch and brake stack consisting or multiple alternating friction discs and drive plates

- A centrally located piston between the brake and clutch that will engage either the clutch, or brake, but never overlap to engage both at the same time

- The piston seals (o-rings with Teflon liners with each o-ring)

- Springs tending to push the piston to the brake side (there are many combinations of springs and pressure called logic types)

- The transmission fluid that make the whole unit possible

UNIQUE FEATURES AND BENEFITS

The PosiClutch provides quiet, smooth, maintenance-free, operation with no adjustment or regular downtime required. It features a totally-enclosed, heavy duty, foot mounted, cast iron sealed housing for operation in dirty, dusty, wet environments. Inside or outdoors, at manufacturing facilities, on barges or boats, or high-volume emergency flood water control wherever it is installed, the PosiClutch functions with no regular adjustment or maintenance intervention during its 40,000,00-cycle design life (annual fluid changes are suggested for maximum service life).

This proven design includes an internal brake that can be released to allow free movement of the output for inspection or freeing a jam. A proprietary controller communicates through the J-1939 communications protocol typically used on most engines. These include limiting engagement at proper engine speed, overload protection if the engine overloads and falls below a specified speed (preventing engine stall condition), detection preventing clutch damage. This control can also be used for remote start enabling the clutch to be properly engaged remotely, or automatically eliminating the need for personnel in the area.

The multiple disc friction stacks provide high torque and thermal capacity in a low inertia (only 61 pounds per square foot) compact package. Highly developed friction materials function optimally with the transmission fluid and resist wear. Teflon liners protecting every piston o-ring seal eliminates cracking and leaking of the o-ring seal, and provides smoother quicker engagement. Because there is virtually no wear of the friction material, piston travel is reduced, utilizing less actuation air or hydraulic fluid, and providing a quicker response.

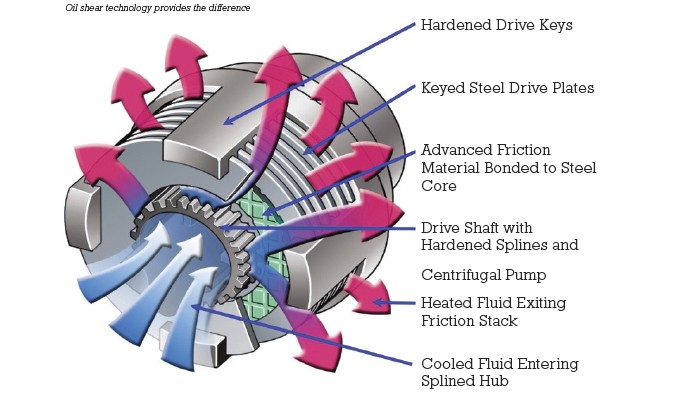

OIL SHEAR TECHNOLOGY

Oil shear technology is the heart of all Force Control clutches and brakes. Transmission fluid flowing through the friction stack is put in a shear condition during dynamic engagement. It transmits torque between the friction discs and drive plates, protecting the parts from mechanical contact, and absorbing the heat of engagement as it flows through the stack. Upon exiting the stack it flows down the housing walls where it is cooled and back into the bottom of the unit to re-circulate back into the friction area. As the pressure continues to clamp the friction stack together it reaches a point of static lock up unless continuous slip is a desired condition.

The transmission fluid also serves to lubricate the bearings and splines for greatly improved operating life. Depending on the thermal loads the additional cooling of the transmission fluid can be done with fan cooling, water cooling, external oil-to-air cooling, or oil-to-water cooling. The PTO clutches can use engine coolant for additional cooling, if desired.

ABOUT THE AUTHOR

Stan Porter can be reached at 513.868.0900 or sporter@forcecontrol.com. Headquartered in Fairfield, Ohio, Force Control Industries is the world leader in oil shear technology, offering a full line of clutches, brakes, and clutch brakes for diverse severe duty applications. Their manufacturing campus includes three manufacturing facilities with over 100,000 square feet of manufacturing space along with engineering, design, customer support and administrative offices. All facilities are ISO9001/2000 certified for quality assurance. For more information, email sales@forcecontrol.com or visit www.forcecontrol.com.

_______________________________________________________

MODERN PUMPING TODAY, November 2018

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!

![]()