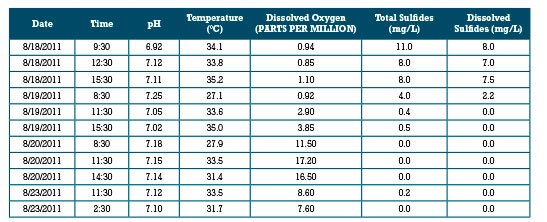

Aside from H2S vapor levels, the total and dissolved sulfides and DO levels (liquid phase) should be examined. For this discussion, only the grab samples collected by the third party will be used. Since both data sets have been shown to be, for the most part, in agreement with each other, this both limits any potential sampling bias as well as simplifies the analysis by only using one data set. This data set, shown in table 5, is also very complete and has a high level of precision, augmenting the chart in figure 14 from last month’s installment.

For the duration of the sampling, pH stayed relatively constant at slightly above 7, averaging 7.11, and the temperature was in the range of 27.1 to 35.2 degrees Celsius, averaging 32.4. These are relatively normal values for this location and time of the year, indicating that temperature and pH did not play a significant role in the reductions achieved and can be eliminated as alternate explanations for reduced H2S concentrations. What does change significantly is sulfide and DO concentrations, especially in the range highlighted.

Table 5: Third Party Grab Sample Results at MH1

August 19 is when significant changes occur, for reasons that have already been discussed, and the data above further illustrates the point. The reduction in total and dissolved sulfides between the last sample on August 18 and the first on the 19th is 50 percent and 70 percent, respectively. While these are great reductions, even better is the 100 percent reduction to both these values that occurs by the time the first sample is collected on August 20 and continues throughout the sampling period. The dramatic rise in DO is also very apparent, increasing from 1.1 to 11.5 parts per million, an increase of over 1000 percent. In regard to the suspected feed line impingement mentioned above, it is interesting to note the decrease in DO levels that takes place on August 23, although the levels are still elevated well beyond what is considered aerobic.

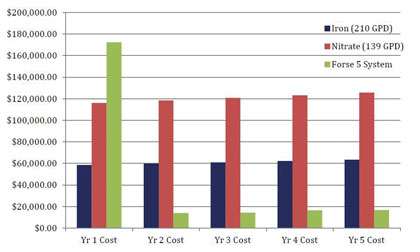

Figure 15: Five-Year Annual Costs for Iron, Nitrate, and FORSe 5 Hydrogen Sulfide Treatments

CONCLUSION

The current methods of odor control being employed by utilities and municipalities create technical and financial compromises. The technical compromises tend to produce undesirable side effects, ranging from infrastructure corrosion to clogging to actually facilitating the sulfide producing anaerobic slime layer. Additionally, the use of chemicals requires ongoing and escalating year-over-year expense, stressing operations budgets. Often, these technical and financial challenges impact performance and compromise results.

Anue Water Technologies has introduced a new technology that concurrently advances the effectiveness of treatment and decreases ongoing cost. Using the sustainable approach of onsite oxygen and ozone generation, the FORSe 5 system has demonstrated its ability to quickly and completely control H2S production and increase DO levels under extreme conditions.

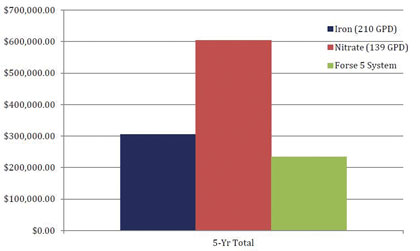

Figure 16: Total Five-Year Costs for Iron, Nitrate, and FORSe 5 Hydrogen Sulfide Treatments

The theory of operation is supported by pilot tests cited herein. Furthermore, this treatment is accompanied by minimal to zero negative side effects. In these terms it is a much more effective means of treating wastewater collection systems for odor and corrosion than traditional methods.

To illustrate the cost effectiveness of FORSe 5, consider the situation where a municipality is using, on average, 210 gallons of iron salts per day in one of their force mains. For nitrates, the approximate stoichiometric equivalent is about 33 percent less usage than iron, or about 139 gallons per day. The costs associated with these treatment methodologies can then be compared to that of an appropriately sized FORSe 5 system, which would actually be expected to provide a higher level of overall performance, over a number of years, so that an accurate comparison can be made between them, as shown in figure 15.

The assumptions used to create this chart were:

- Iron – 210 GPD average usage at $0.75/gallon;

- Nitrate – 139 GPD average usage at $2.25/gallon;

- FORSe 5 – Capital equipment cost and operating costs of 16 kW @ $0.08/kWh, 24 hrs, 365 days, miscellaneous consumbles;

- All costs are assumed to increase at a rate of 2 percent annually, which is believed to be very conservative.

It is clear that after the first year, costs associated with FORSe 5 quickly fall below those associated with chemical usage. To further illustrate this, the total five-year costs associated with each treatment methodology are shown in figure 16.

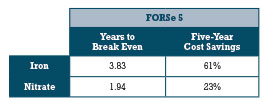

Figure 16 clearly indicates that a FORSe 5 system will be less expensive to operate over five years than either of the two other treatment chemicals discussed here, which are basically the two ends of the chemical pricing spectrum. The actual years to break even and total five-year cost savings are included in table 6.

Table 6: FORSe 5 Years to Break Even and Five-Year Cost Savings

Additionally, what are not included in the chemical costs are the unseen costs; the potential for damage to infrastructure or increased usage issues that were discussed previously. This is in sharp contrast to the fact that FORSe 5 systems will tend to improve the collection system environment over time, as has also been previously discussed.

Overall, the application of oxygen and ozone into the wastewater environment brings with it not only a much more technologically and cost effective means of treatment than traditionally available, but is also much more effective from a sustainability standpoint, an issue that is gaining in both technological and social importance. ◆

Anue Water Technologies is a privately owned, U.S. company dedicated to providing innovative solutions for improving the processing and treatment of water and wastewater. Anue serves the global market with a network of sales representatives and service providers to actively support applications development, leading to optimized solutions—working with municipalities, wastewater operating, and industrial companies who encounter challenges with wastewater, to create tailored, highly effective solutions for treating odor and corrosion. For more information, visit www.anuewater.com.

____________________________________________

MODERN PUMPING TODAY, October 2017

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!

![]()