Sewage collection systems have long been subject to issues with odor and corrosion, which is understandable given the nature of what they convey. Sewage odor, the rotten egg smell almost everyone has experienced, is a localized and political issue and is really the driving force behind implementing controls in sewage collection systems. Corrosion, however, is the issue with the greatest potential for environmental harm and real systemic and economic damage. This damage can arise in the form of burst pipes, lift station degradation, and other similar forms of equipment and system failure. Failures of this type not only require the repair and replacement of collection system materials and equipment, but also have the potential to expose the environment to unpredictable releases of hazardous waste that are very difficult, if not impossible, to contain or recover. In fact, according to the ASCE’s 2009 Infrastructure Report Card [ASCE, 2009], where a grade of “D-” was given:

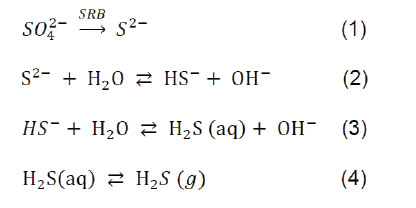

A major contributor to odor and corrosion in these systems is hydrogen sulfide (H2S) and its associated compounds. All human waste, and subsequently, all wastewater, contains sulfur compounds, which provide the molecular basis for the generation of hydrogen sulfide. Hydrogen sulfide arises from the combination of anaerobic conditions and the presence of sulfites and sulfates in conjunction with the colonies of microorganisms present on the inner walls of all collection system, referred to as the slime layer. Sulfate reducing bacteria (SRB) will utilize these compounds in the absence of free oxygen (O2) for metabolism. These bacteria do not actually utilize the sulfur component, and it is available to react with water, specifically free protons (H+), which results in the generation of hydrogen sulfide. This generation pathway can be represented by the following balanced reactions:

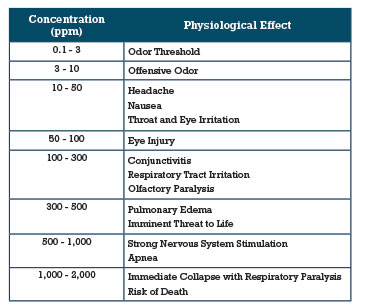

Following its generation, hydrogen sulfide can be released into the atmosphere, as shown in equation (4), and find its way to receptors through manholes or other junctions of the atmosphere and collection system, at which point it is an odor concern. Hydrogen sulfide is a colorless gas that has a characteristic rotten egg odor, is highly toxic and is very corrosive to certain metals. It is heavier than air, meaning it can accumulate in wells, manholes, and other similar locations that do not have much ventilation. The effect it can have on humans, at varying concentrations relative to ambient air, is shown in table 1.

Table 1 – Hydrogen Sulfide Health Effects at Varying Concentrations

Hydrogen sulfide becomes a corrosion issue when it comes into contact with moist concrete or steel, among other metals, in the presence of oxygen, even at very low gaseous concentrations. Conditions such as these are fairly common in the headspace of some pipes as well as at manholes, lift stations, and other areas where the collection system is provided with easy access to atmospheric oxygen. Bacteria in these areas are able to convert the H2S into sulfuric acid (H2SO4) which then begins to react with the infrastructure in a destructive manner.

Historically, control of odor or corrosion has been implemented through either vapor phase techniques, where the headspace of a lift station is treated, or liquid phase techniques, where treatments target the liquid flow. Vapor phase treatments like scrubbers do not provide corrosion control, as opposed to liquid phase techniques, some of which can offer corrosion control. The most common method of inducing liquid phase treatment, or directly treating the wastewater, inside the collection system, has been by drip dosing chemicals into the systems. A constant and continuous dose of chemical is fed from a large reservoir with a small pump into the collection system, typically at a manhole or pump station. These chemicals are meant to react with the odor causing compounds present in the wastewater or cease their formation and/or release from solution.

A LOOK AHEAD

The main classes of reactions used for control of hydrogen sulfide include oxidation, sulfide scavengers (iron salts), pH adjustment, alternate oxygen source/sulfate substitute, and the combined use of oxygen and ozone for treatment. We will go into deeper detail for each of these methods in part 2 of this series, but for now, it is important to note that, in terms of a robust and green methodology for the treatment and prevention of odor and corrosion in collections systems, the combined forces of oxygen and ozone are at the top of the list.

In parts 3 through 5, we will walk through the experimental conditions applied for testing conducted at a municipal waste water district in southern Arizona that had received numerous complaints from an upscale neighborhood regarding the presence of strong sewage odor—and the applied solution we brought to bear. Anue Water Technologies (AWT) of San Diego, California, designs and manufactures a comprehensive range of systems, referred to as FORSe 5™, that utilize oxygen and ozone for effectively inducing clean, sustainable and cost effective treatment of odor and corrosion in collection systems.

The direct treatment of the wastewater is achieved through a proprietary process of treating a factional flow of wastewater and returning this treated flow into the untreated flow, thus inducing change. This process is termed hydrodynamic infusion. ◆

Anue Water Technologies is a privately owned, U.S. company dedicated to providing innovative solutions for improving the processing and treatment of water and wastewater. Anue serves the global market with a network of sales representatives and service providers to actively support applications development, leading to optimized solutions—working with municipalities, wastewater operating and industrial companies who encounter challenges with wastewater, to create tailored, highly effective solutions for treating odor and corrosion. For more information, visit www.anuewater.com.

____________________________________________

MODERN PUMPING TODAY, June 2017

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!

![]()