As global conditions place more stress on water resources, a great deal of attention is being paid to water reuse technologies, particularly those that facilitate the reuse of the next level of difficult-to-treat or highly variable raw water sources. New hollow fiber ultrafiltration membrane technology is proving to be key to successful water reuse strategies for available water sources, especially those with high solids. The membranes can achieve higher recoveries for industrial water, work well for seawater pre-treatment, and are even being used for potable water treatment.

One recent example is the PURON® MP pressurized hollow fiber ultrafiltration (UF) treatment system for high solids water and wastewater, developed and manufactured by Koch Membrane Systems (KMS). The new technology has achieved excellent results in thirteen pilot tests around the globe, with full-scale systems under construction in China and Singapore. The membrane produces high quality permeate at low fouling rates with difficult feed water. The design has a smaller footprint and uses less energy and chemicals than other wastewater treatment options, offering lower lifecycle costs for difficult-to-treat water.

GLOBAL TRENDS FAVOR WATER REUSE

Governments around the world are shifting focus to water reuse strategies as population growth and global development places a strain on existing fresh water supplies. In addition, wastewater reuse in both the industrial and municipal sectors has become more prevalent in recent years as the cost and regulations for waste disposal increase. Treated wastewater effluent can be used for agricultural and landscape/golf course irrigation, industrial cooling processes, and indirect potable reuse.

Water reuse strategies are taking hold around the United States with more systems coming online every day. In New York State watersheds, many wastewater plants use UF membrane filtration before discharging wastewater effluent to aquifers. In more arid environments that are experiencing water scarcity, like those in California, Arizona, and Nevada, membrane plants are common.

In some cases reclaimed water is distributed around a municipality for a variety of purposes through a completely separate water main, leading to increased overall water use efficiency.

As some sources of usable fresh water dry up or otherwise become unavailable, other alternatives are becoming more attractive, including difficult-to-treat sources such as brackish water, pond water, or seawater. Ultrafiltration products are being developed to process the vast number of feed streams that are not clarified enough to be processed by drinking water membranes currently in place.

In the case of surface waters, like reservoirs, lakes, and rivers, these alternative water sources can be highly variable in terms of suspended solids or turbidity. High solids and increased levels of total organic carbon (TOC), tend to wreak havoc on conventional water treatment equipment. A storm rolling across a shallow lake can churn up sediment causing a peak turbidity event. In a lake with an average turbidity of 5-10 NTU, a storm could cause a spike in turbidity levels to 100-200 NTU, or even as high as 1000 NTU. In the case of rivers, a 2-inch (50.8 millimeters) rainfall can cause excessive runoff from roads to flow into the river. When the flow of this murky water enters a treatment plant using sand filter or clarifier technology, the plant often cannot meet set turbidity output standards.

Filtration challenges are increased by other factors as well, such as seasonal change, storm runoff, and water temperature changes. Variability in suspended solids or turbidity is often introduced to water sources as seasons change. Finally, filtration is more difficult in colder water, as increased viscosity makes it more difficult to push water through a membrane filter.

Primary lagoon and blower building

NEW ULTRAFILTRATION TECHNOLOGY MEETS THE NEED FOR PERMEATE CONSISTENCY

In response to the need for end-users to achieve consistent permeate under highly variable conditions, KMS developed the PURON MP ultrafiltration membrane. This product was specifically designed for high-solids water and wastewater applications, including surface water treatment, high TOC water treatment, RO pretreatment, and tertiary wastewater treatment. A combination of robust membrane fibers and a unique cartridge design allows the PURON MP product to withstand the stress of high turbidity events with surprisingly effective flux recovery.

A 4-year research and development process began with an early prototype placed at a reservoir test site with moderate to high TOC levels. This pilot, located near the KMS Wilmington, MA, manufacturing facility, ran for about a twenty-four months as researchers and engineers evaluated operating modes, cleaning sequences, and cartridge designs to come up with an optimum configuration. Tests were conducted on air scouring, backflushing and chemical cleaning; the results were used to fine-tune the cleaning sequences.

Following extremely positive test results, engineers developed and tested additional prototypes with different packing densities to arrive at the optimum number of fibers to place in each cartridge. The optimized system has been tested on different applications at more than ten surface water or municipal wastewater pilot sites in the United States, Australia, China, Brazil, Italy, and Spain. The tests have been used to optimize operating parameters and demonstrate long-term performance on a wide variety of feed water sources. Full scale systems are currently being installed at industrial facilities in China and Singapore.

PILOT TESTING SHOWS EXTREMELY HIGH TOLERANCE OF SOLIDS

Pilot test findings indicate that the membranes can tolerate an extremely high level of solids even after significant storm events, producing consistent permeate no matter which type of raw water is received.

At one pilot site, the feed water was a river with periods of extremely high solids due to rains and runoff. Even with measured turbidity peaks up to 8000 NTU, while the pilot would see an increase in transmembrane pressure (TMP), no unusual cleaning was necessary to return the cartridge to baseline TMP after the turbidity spike cleared. In general, even with these very high upsets, the permeate turbidity did not increase above 0.1 NTU.

At another site (pictured), feed water consisted of high fouling lagoon wastewater plant effluent with high TOC and incomplete nitrification. The change from fall to winter brought a snowfall that caused the lagoon to “flip”, causing TOC readings to jump from 12-15 parts per million to more than 20 parts per million. Even so, the membrane cartridge consistently produced permeate with very low turbidity and silt density index (SDI) values, demonstrating excellent water reuse potential regardless of feed water turbidity and TOC.

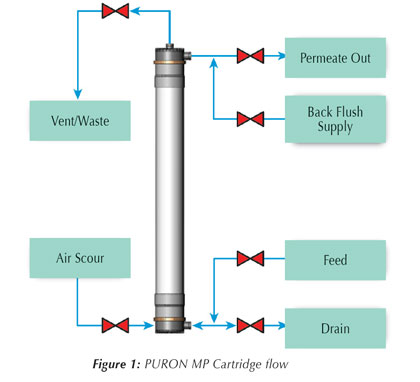

Operators back flushed the pilot witha 20 minute cycle during the lagoon flip event, allowing the facility to stay clean without high TMP. The pilot operated well through the winter with very low temperatures and in high feed TOC conditions at 25 gallons per square foot (1018 liters per square meter) of membrane per day (GFD) with a clean in place (CIP) interval of thirty days. In addition, the unit also demonstrated very high coagulant dosing tolerance. Tests with an on-line permeate UV254 instrument showed that coagulant dosage can be optimized for more efficient chemical consumption, rather than dosing excessive, expensive concentrations to ensure that worst case conditions are managed. Figure 1 shows the flow through the membrane cartridge.

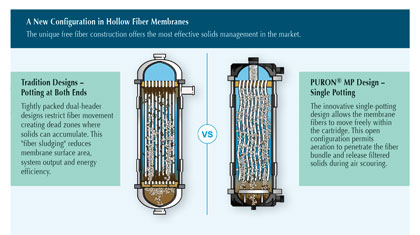

Figure 2: Comparison of potting designs

UNIQUE FEATURES REDUCE FIBER SLUDGING

The design of the PURON MP modules includes features that make them more forgiving for use in difficult-to-treat waters and better able to handle high solids without fiber sludging. Because the PURON MP cartridge utilizes a strong reinforced hollow fiber, the membranes are able to be bound or “potted” at the top end only. This single-potting design allows the membrane fibers to move freely within the cartridge, thereby allowing air scouring to penetrate the fiber bundle more completely and release accumulated solids to the bottom, where they are easily drained away. In addition, backflush discharge is in the center of the cartridge, the zone most likely to experience sludging.

By contrast, other hollow fiber membrane cartridges utilize traditional designs with potting at both ends. The tightly packed dual-header configuration in these traditional modules restricts fiber movement, creating dead zones where solids can accumulate. This fiber sludging reduces membrane surface area, system output and energy efficiency. Figure 2 shows a comparison between the two approaches.

Another advantage of the PURON MP system setup is that being able to rely on automated cleaning sequences to keep the membrane clean during difficult turbidity events, eliminate the need to take down the system for intensive chemical cleaning. Air scouring, backflushing, and draining keeps TMPs lower so operators do not have to come in on an emergency basis to deal with these types of events.

The cartridge uses a virtually unbreakable braided reinforced fiber, which minimizes the type of damage that could shut a system down or contaminate the permeate. This results in improved uptime, ensuring the system can operate at full capacity, so there are no deleterious effects on downstream processes. Figure 3 shows the fibers, the cartridge and the complete PURON MP skid.

The PURON MP system’s high flux and solids tolerance properties eliminate the need for costly clarifiers and chemical pretreatments in many tough applications. This reduces the footprint required, limiting initial capital expenditure as well as operating costs associated with chemical use. Advanced membrane chemistry, a tight pore size and distribution and effective air scouring can deliver more stable performance without the need for extensive chemical cleans.

SIMPLE OPERATIONS AND LOWER TOTAL COST OF OWNERSHIP

The new pressurized hollow fiber UF cartridge technology by KMS produces high quality permeate at low fouling rates with difficult feed water. The cartridge design incorporates a single header design with free floating, reinforced fibers that allow for solids removal during cleaning. Simplifying operation, the new membrane eliminates clarifier pretreatment in many applications, minimizes downtime, and reduces chemical usage. These benefits add up to a lower total cost of ownership. ■

About The Author

Kevin Phillips is product development manager at Koch Membrane Systems. For half a century, KMS has been a world-class developer and manufacturer of innovative membrane filtration systems serving a global marketplace. KMS solutions are at work today in a wide variety of markets that include municipal and industrial water and wastewater processing; dairy, juice, and wine processing; industrial biotechnology; and many more. For more information, visit www.kochmembrane.com.

MODERN PUMPING TODAY, April 2015

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!