Metallized Carbon Corporation, a global leader in the manufacture of oil-free, self-lubricating, carbon-graphite materials for severe service lubrication applications, is committed to expanding the benefits these products can offer to a range of applications.

For example, today’s rotary vane pump users can now benefit from custom vanes, rotors, and end plates for use in pumping both liquids and gases. The carbon-graphite components provide superior lubrication in most environments, and are ideal for pumping liquids with poor lubricating qualities, strong chemicals that attack metals, and to pump air, vacuum, combustion products and gasoline vapors. Also, aviation engineers are discovering the benefits of carbon- graphite bushings for use in aircraft engine gear pumps that pump fuel.

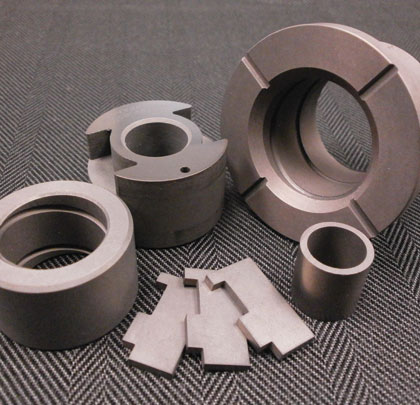

CUSTOM VANES, ROTORS, AND END PLATES FOR ROTARY PUMPS

Metallized Carbon’s carbon-graphite vanes, rotors, and end plates are used in such dry running applications as automotive anti-smog pumps and gasoline vapor pick up pumps, breathable air pumps and vacuum pumps. In-liquid applications include vending machine beverage pumps, fuel and liquid chemical pumps, and medical liquid pumps.

Metallized Carbon supplies the carbon-graphite vanes, rotor, and end plates to rotary pump and compressor manufacture and rebuilders. The materials are chemically resistant and are compatible with FDA food and beverage regulations. They have a low wear rate running in both gas atmospheres and low viscosity liquids.

IDEAL FOR BOTH LIQUIDS AND GASES

Carbon graphite vanes can withstand the rubbing of the vane tip against the housing bore and the rubbing of the side of the vane against the slots in the rotor. Lightweight carbon graphite rotors save energy and withstand the rubbing against the vane and the end plates. Carbon graphite end plates are pressure tight and dimensionally stable so that they can make a close clearance seal with the rotor and vanes. They also withstand the rubbing of both the vanes and rotor.

These materials work best in severe service applications With dimensionally stability and high strength-to-weight ratio, the components are available in several grades of Metcar’s proprietary carbon/graphite material. Metcar engineers assist in selecting the optimum grade based on application, environment, housing materials, revolutions per minute, and other parameters. The components can be supplied to meet custom prints and specifications.

CARBON-GRAPHITE BUSHINGS FOR AIRCRAFT ENGINE FUEL PUMPS

A more unique severe service lubrication application for carbon- graphite bushings is in use in gear pumps that pump aviation fuel for aircraft engines. Here, the carbon-graphite bushings are used to support both the drive gear shaft and the idler gear shaft. Metcar carbon-graphite bushings are preferred for this application because they can use aviation fuel as the bushing lubricant.

Aviation fuel is a low viscosity liquid that produces only an extremely thin hydrodynamic film, too thin to provide adequate lubrication for traditional metallic bushings. But since carbon-graphite material—in contrast—has no atomic attraction to a metallic shaft, the thin fuel film is sufficient to lubricate metallic shafts running in the carbon-graphite bushings.

UNIQUE MATERIAL WITH NUMEROUS ADVANTAGES

A second major advantage of carbon-graphite bushings is that they are self-lubricating—they can run dry for short periods of time without catastrophic pump failure or significant wear. In addition, carbon-graphite bushings are dimensionally stable, which permits the close bushing to shaft running clearances that are required in gear pump applications.

Finally, these carbon-graphite bushings have a relatively low elastic modulus. While elastic enough that they can be press-fit into the metallic gear pump housing with no difficulty, after being properly press-fit, the carbon-graphite bushings are pre-stressed in compression. Therefore, they exhibit nearly the same coefficient of thermal expansion as the metallic gear pump housing material. This assures that the running clearance between the shafts and the bushings will remain the same throughout the entire operating temperature range of the pump. ■

About The Author

Matthew Brennan is president and CEO of Metallized Carbon, an ISO certified and producer of the Metcar brand of solid, oil-free, self-lubricating materials. For additional information about the company and its services, visit www.metcar.com or call 914.941.3738.

MODERN PUMPING TODAY, September 2014

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Pumping Today Magazine!